Method and device used for forging and pressing hard disk drive substrate with extension height

A hard disk drive, forging technology, applied in the direction of forging/pressing/hammer device, forging press, forging press, etc., can solve the problem of harmful, flowing into or leaking from the completed hard disk drive substrate, extending the hard disk drive Substrate and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

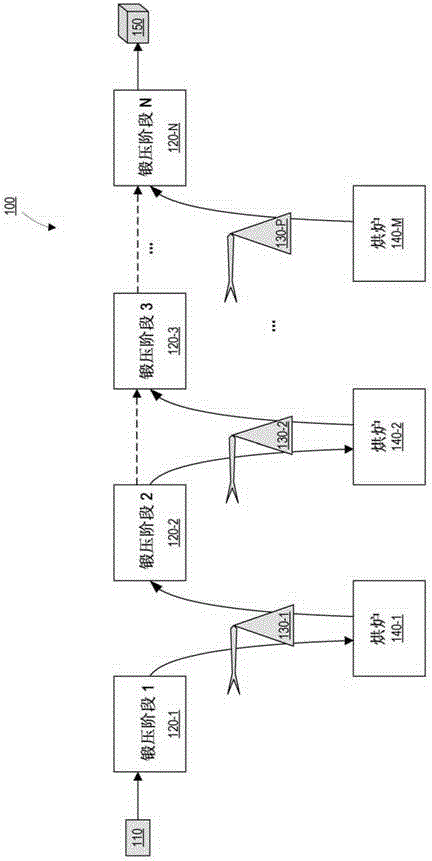

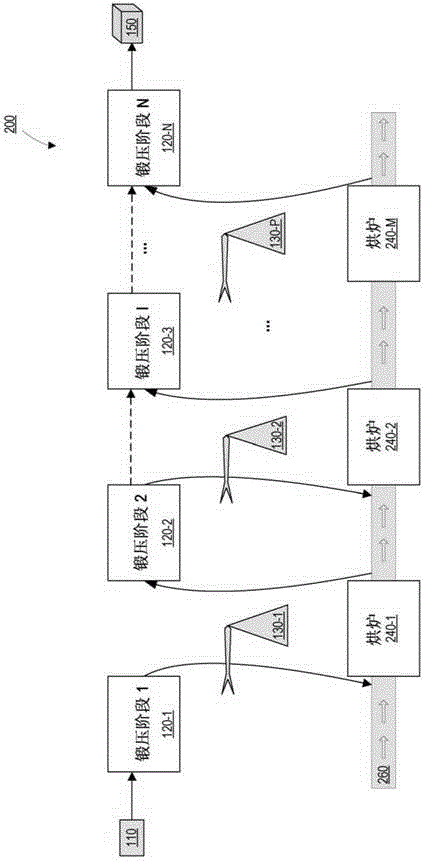

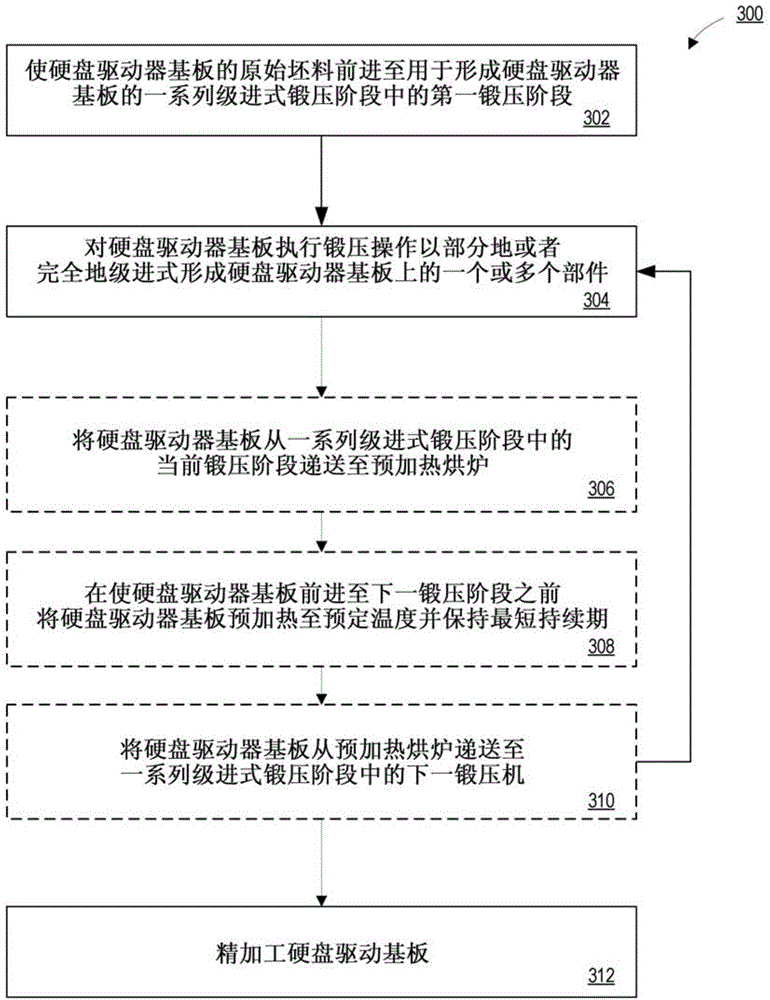

[0013] figure 1 One embodiment of a system 100 for swaging a hard disk drive substrate having an extended height is shown. In one embodiment, metal extruded sheet 110 is progressively formed in a series of transfer dies over a series of progressive forging stages (eg, stages 120 - 1 to 120 -N) to form hard disk drive substrate 150 . The pressplate of the transfer die that performs the forging operation is either coated with a titanium nitride (TiN) coating or made of high speed steel or carbon tool steel to increase the hardness of the pressplate and to increase the tool use of the pressplate Life, and improve forging efficiency. In one embodiment, additional press processing operations are performed in additional stages using additional machines (not shown) to further form the hard disk drive substrate, including trimming, punching, stamping, embossing, or other suitable processing.

[0014] In one embodiment, the metal used in the series of stamping stages used to form the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side wall height | aaaaa | aaaaa |

| Side wall height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com