Chemical nickel-plating waste liquor treatment method and system

A waste liquid treatment system and electroless nickel plating technology, applied in chemical instruments and methods, metallurgical wastewater treatment, special compound water treatment, etc., can solve problems such as inability to remove nickel, large stability constant, etc., to save energy and simplify the system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

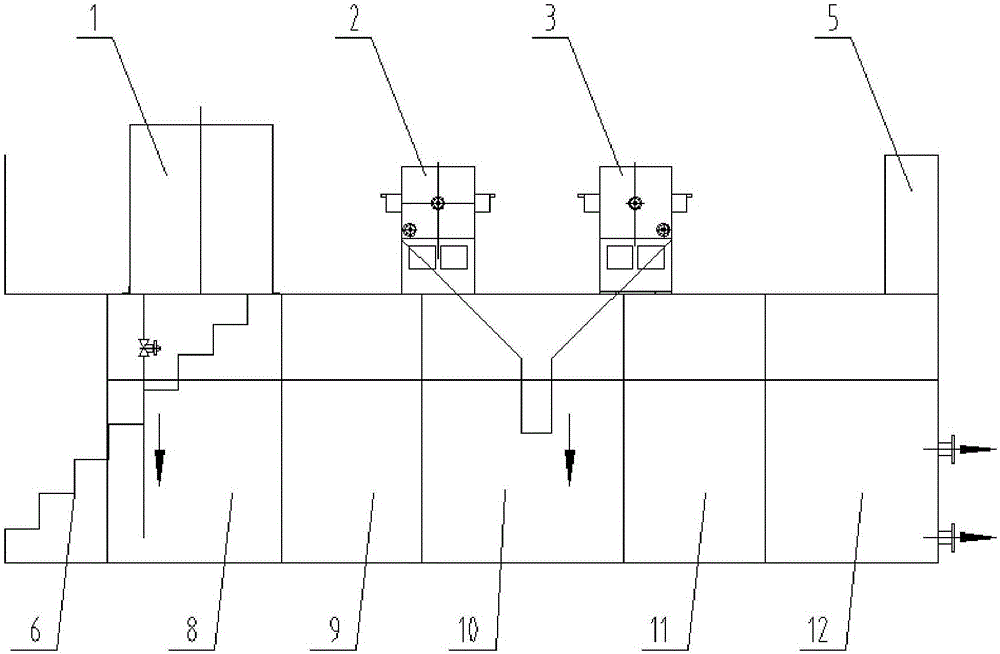

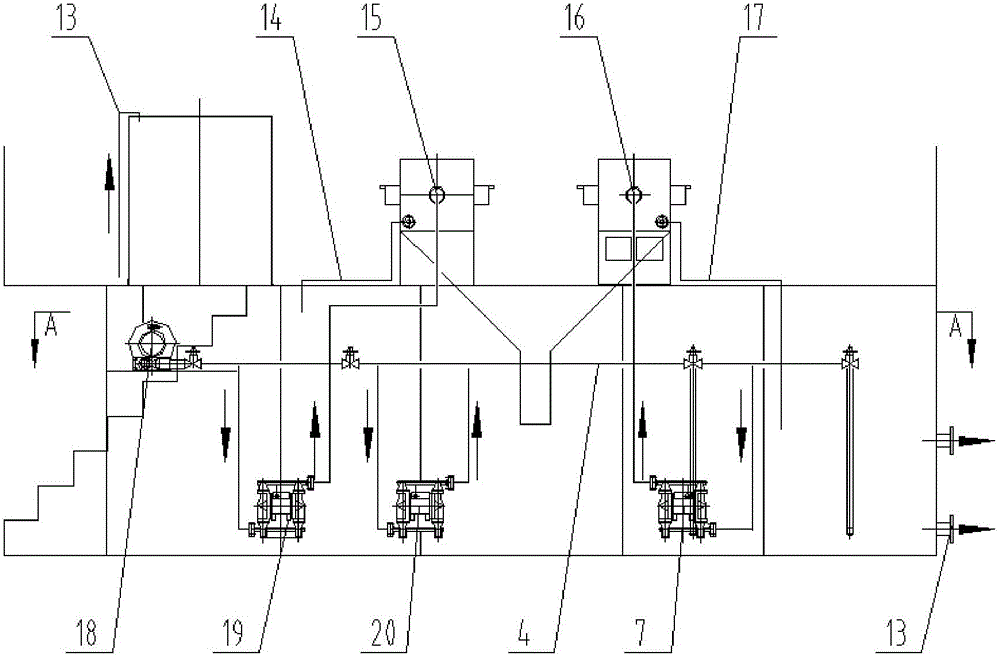

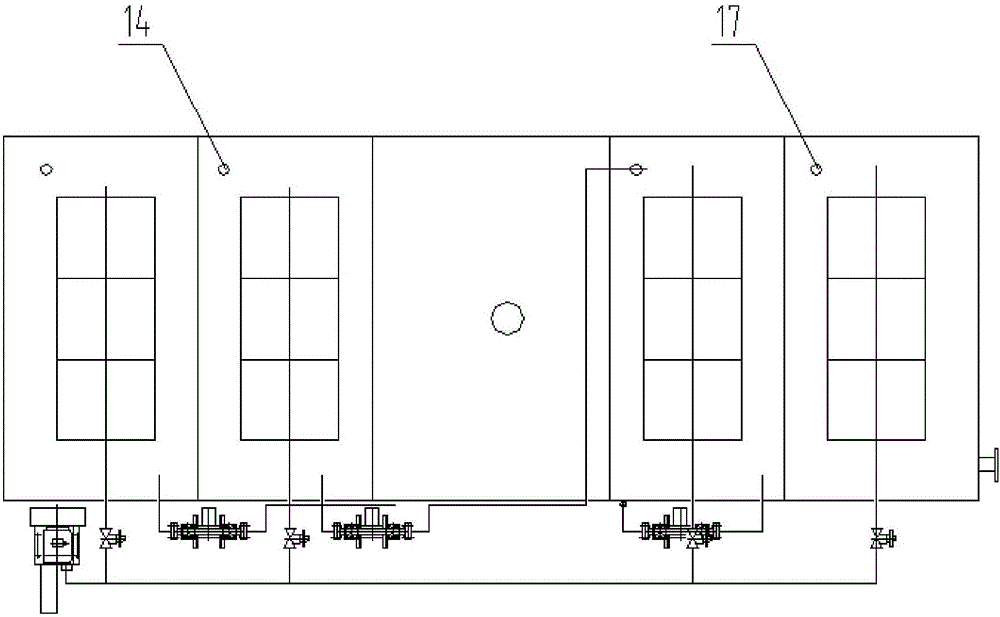

Image

Examples

Embodiment 1

[0063] A method for treating waste electroless nickel plating solution, comprising the following steps:

[0064] Use calcium hydroxide to adjust the pH value of the electroless nickel plating waste solution to 8-8.5, add 2g of barium chloride per liter of waste solution to carry out the complexation reaction, then adjust the pH value of the solution to 11-12, and then add PAM to carry out coagulation and precipitation to obtain the first mixed solution;

[0065] performing solid-liquid separation on the first mixed liquid to obtain a first filtrate;

[0066] The first filtrate is neutralized to achieve recovery and discharge.

Embodiment 2

[0068] A method for treating waste electroless nickel plating solution, comprising the following steps:

[0069] Use calcium hydroxide to adjust the pH value of the electroless nickel plating waste solution to 8-8.5, add 4g of barium chloride per liter of waste solution to carry out the complexation reaction, then adjust the pH value of the solution to 11-12, and then add PAM to carry out coagulation and precipitation to obtain the first mixed solution;

[0070] performing solid-liquid separation on the first mixed liquid to obtain a first filtrate;

[0071] The first filtrate is neutralized to achieve recovery and discharge.

Embodiment 3

[0073] A method for treating waste electroless nickel plating solution, comprising the following steps:

[0074] Use calcium hydroxide to adjust the pH value of the electroless nickel plating waste solution to 8-8.5, add 3g of barium chloride per liter of waste solution to carry out the complexation reaction, then adjust the pH value of the solution to 11-12, and then add PAM to carry out coagulation and precipitation to obtain the first mixed solution;

[0075] performing solid-liquid separation on the first mixed liquid to obtain a first filtrate;

[0076] The first filtrate is neutralized to achieve recovery and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com