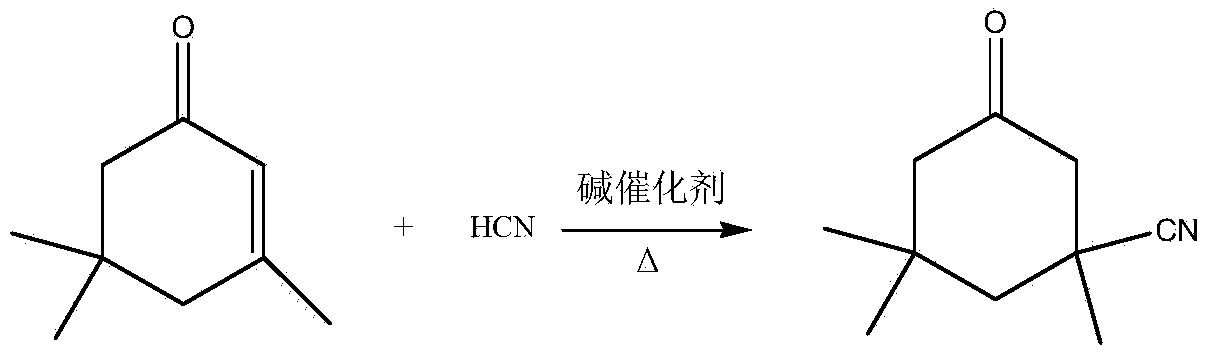

Improved method for treatment of isophoronenitrile reaction solution

A technology of isophorone nitrile and isophorone, which is applied in the process field of secondary neutralization and treatment, can solve the problems of increased side reactions, etc., achieve stable operation of the device, reduce equipment and safety costs, and reduce high polymer The effect of equal solid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

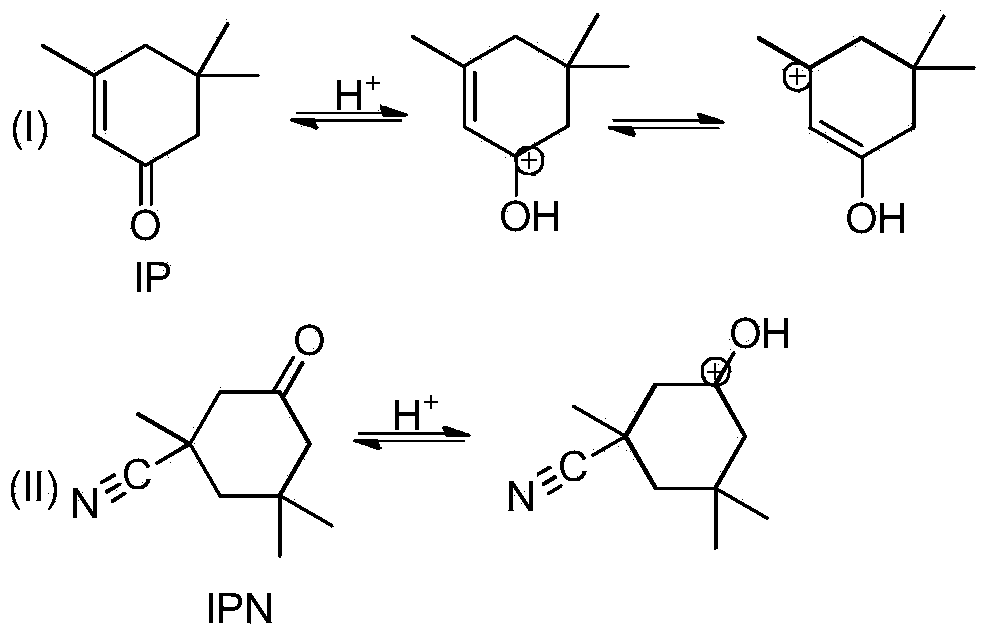

Problems solved by technology

Method used

Image

Examples

Embodiment 1

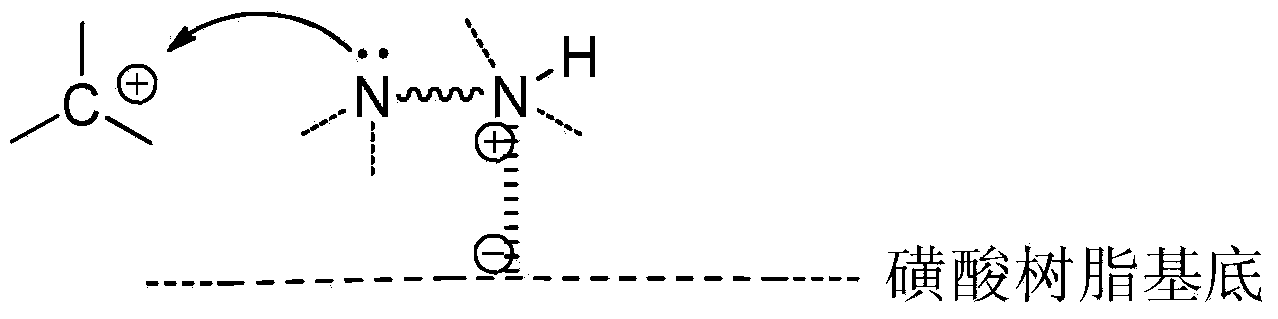

[0046] The acidic cation exchange resin is AMBERLITE IR120H. If the resin leaves the factory in sodium form, it needs to be washed or backwashed several times with hydrochloric acid or sulfuric acid solution to convert it into hydrogen form, and then washed with soft water. AMBERLITE IR120H has a pore size between 80-100nm and a total mass exchange capacity of 4.5mmol / g. It is filled in a tubular container with a filling capacity of 87kg.

[0047] (1) Add 5.5g of ethylenediamine and 32.5g of phenylenediamine (the total molar weight is about 0.1% of the molar weight of the hydrogen ion of the sulfonic acid group in the resin) to 380kg of isophorone to make a mass content of about 0.01% IP solution of the diamine at 10 °C. The solution was transported into a tubular container filled with resin, and flowed through the entire resin layer for a residence time of 5 minutes to modify the strongly acidic cation exchange resin.

[0048] (2) Under 150 ℃, 1350kg isophorone and 135kg hyd...

Embodiment 2

[0054] The strongly acidic cation exchange resin is selected from German Bayer Lewatit Monoplus S100. If it is in the sodium form at the factory, it will be converted to the hydrogen form by referring to the method of Example 1. In the tube container, the filling quantity is 250kg.

[0055] (1) Add 1740g of diethylenetriamine (the total molar weight is about 1.5% of the hydrogen ion molar weight in the sulfonic acid group in the resin) to 1740kg of isophorone to make diethylenetriamine with a mass content of about 0.1%. Amine solution in isophorone at 30°C. The solution is transported into a tubular container filled with resin, flows through the entire resin layer, and stays for 10 minutes to modify the strongly acidic cation exchange resin.

[0056] (2) At 80°C, 1.35t of isophorone reacted with 145kg of hydrocyanic acid under the action of the alkaline catalyst sodium ethoxide, of which 18.2kg of the alkaline catalyst sodium ethoxide, and 1506kg of the reaction solution was ...

Embodiment 3

[0063] Jiangsu Suqing 001×7 is selected as the strongly acidic cation exchange resin. If it leaves the factory as sodium form, refer to the method of Example 1 to convert it into hydrogen form. Jiangsu Suqing 001×7 has a pore size between 100-200nm and a total mass exchange capacity of 4.5mmol. / g, filled in a tube container, the filling amount is 34kg.

[0064] (1) 670g triethylenetetramine (total molar weight is about 3% of sulfonic acid group molar weight in resin) is added in 67kg isophorone, is made into the isophorone solution of 1% triethylene tetramine, temperature is 20°C. The solution is transported into a tubular container filled with resin, flows through the entire resin layer, and stays for 20 minutes to modify the strongly acidic cation exchange resin.

[0065] (2) At 180°C, 1350 kg of isophorone reacted with 135 kg of hydrocyanic acid under the action of the basic catalyst calcium hydroxide, wherein 375 g of the basic catalyst calcium hydroxide obtained 1480 kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com