Titanium dioxide wastewater treatment method favorable for improving utilization ratio of calcium oxide and dehydration property of byproduct gypsum

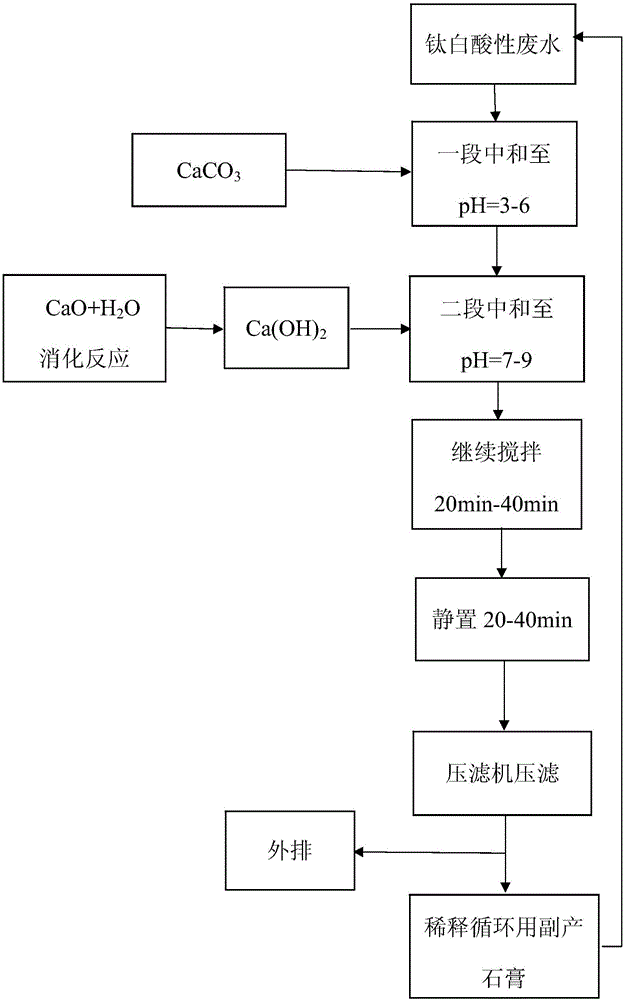

A technology of by-product gypsum and dehydration performance, which is applied in the field of titanium dioxide acid wastewater treatment, can solve the problems of poor dehydration performance of by-product gypsum and low utilization rate of calcium oxide, and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take 400mL of deionized water, heat it to 35°C, and add 80% calcium oxide to the reaction vessel under the condition of stirring intensity of 300r / min to prepare the digested product calcium hydroxide, and dilute it to a concentration of 2wt% hydrogen calcium oxide solution.

[0034] Take 500mL of titanium dioxide acidic wastewater, heat it to 45°C, and add calcium carbonate to the acidic wastewater under the condition of stirring intensity of 400r / min, adjust the pH to 4.5; 30min; then add the diluted calcium hydroxide solution into the acidic wastewater at a flow rate of 5mL / min for the second stage of neutralization, and adjust the pH value to 9. After the neutralization is completed, add 0.1mL cationic polyacrylamide solution (CPAM) with a concentration of 1wt%, and then continue to stir for 30 minutes; after stopping the stirring, let it stand for 20 minutes; Press the by-product gypsum into a filter cake, measure the water content of the filter cake, and compare ...

Embodiment 2

[0038] Take 400mL of deionized water, heat it to 35°C, and add 80% calcium oxide to the reaction vessel under the condition of stirring intensity of 300r / min to prepare the digested product calcium hydroxide, and dilute it to a concentration of 2wt% hydrogen calcium oxide solution.

[0039] Take 500mL of titanium dioxide acidic wastewater, heat it to 45°C, and add calcium carbonate to the acidic wastewater under the condition of stirring intensity of 400r / min, adjust the pH to 4.5; 30min; then add the diluted calcium hydroxide solution into the acidic wastewater at a flow rate of 5mL / min for the second stage of neutralization, and adjust the pH value to 9. After the neutralization is completed, add 0.1mL cationic polyacrylamide solution (CPAM) with a concentration of 1wt%, and then continue to stir for 30 minutes; after stopping the stirring, let it stand for 20 minutes; Press the by-product gypsum into a filter cake, measure the water content of the filter cake, and compare ...

Embodiment 3

[0043] Take 400mL of deionized water, heat it to 35°C, and add 80% calcium oxide to the reaction vessel under the condition of stirring intensity of 300r / min to prepare the digested product calcium hydroxide, and dilute it to a concentration of 2wt% hydrogen calcium oxide solution.

[0044]Take 500mL of titanium dioxide acidic wastewater, heat it to 45°C, and add calcium carbonate to the acidic wastewater under the condition of stirring intensity of 400r / min, adjust the pH to 4.5; 30min; then add the diluted calcium hydroxide solution into the acidic wastewater at a flow rate of 5mL / min for the second stage of neutralization, and adjust the pH value to 9. After the neutralization is completed, add 0.1mL cationic polyacrylamide solution (CPAM) with a concentration of 1wt%, and then continue to stir for 30 minutes; after stopping the stirring, let it stand for 20 minutes; Press the by-product gypsum into a filter cake, measure the water content of the filter cake, and compare t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com