Production method of monopotassium phosphate

A kind of technology of potassium dihydrogen phosphate and production method, which is applied in the direction of chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of backward production technology, single factory establishment, high price, etc., achieve broad market application prospects, simple process, The effect of a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

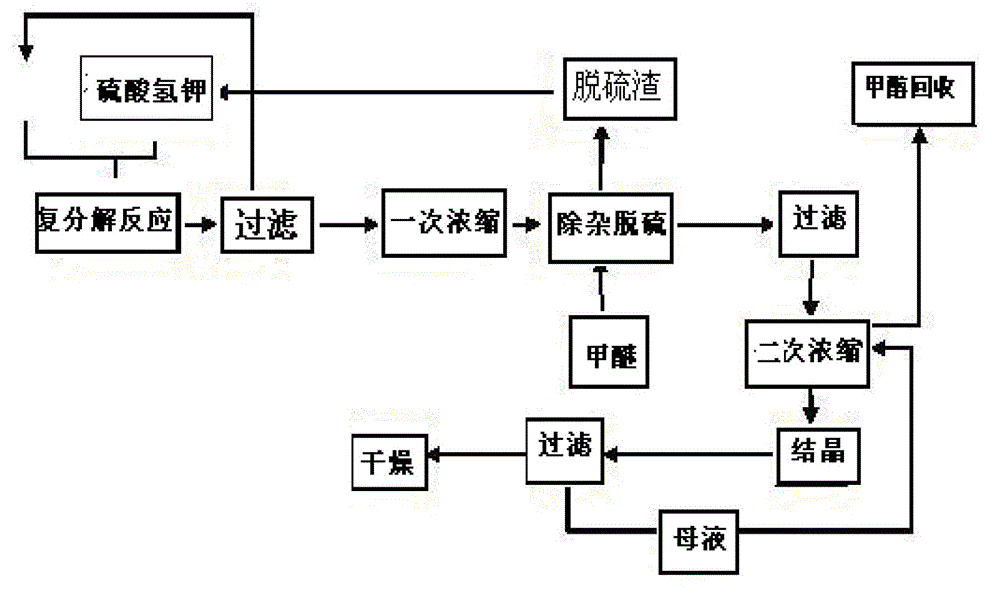

Method used

Image

Examples

Embodiment 1

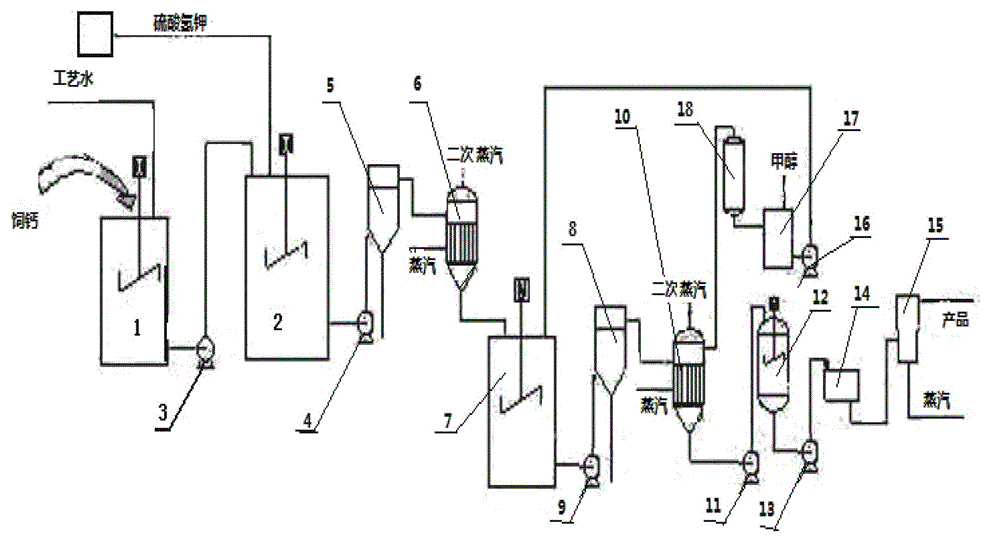

[0013] Potassium dihydrogen phosphate production device is mainly composed of feed calcium slurry tank 1, reaction tank 2, feed calcium slurry pump 3, reaction slurry pump 4, first automatic backwash surface filter 5, primary evaporator 6, impurity removal and desulfurization Tank 7, second automatic backwash surface filter 8, slurry pump 9, secondary evaporator 10, mother liquor pump 11, crystallizer 12, crystal slurry pump 13, flat scraper centrifuge 14, dryer 15, methanol delivery pump 16. Composed of methanol recovery storage tank 17 and methanol condenser 18; wherein the feed calcium feed slurry tank 1 is connected to the reaction tank 2 through the feed calcium feed slurry pump 3, and the potassium bisulfate preparation tank is connected to the reaction tank 2 through pipelines, and the reaction tank 2 Connect with the first automatic backwash surface filter 5 by the reaction slurry pump 4, then connect with the primary evaporator 6 with pipeline, and the primary evaporat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com