Method for improving furfural yield by furfural steam gas phase neutralization

A technology of aldehyde yield and gas phase, applied in the field of biomass energy chemical industry, can solve the problems of waste water discharge polluting the environment, low furfural yield, and high energy consumption of rectification, and achieve energy saving, energy consumption reduction, and purity and concentration improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

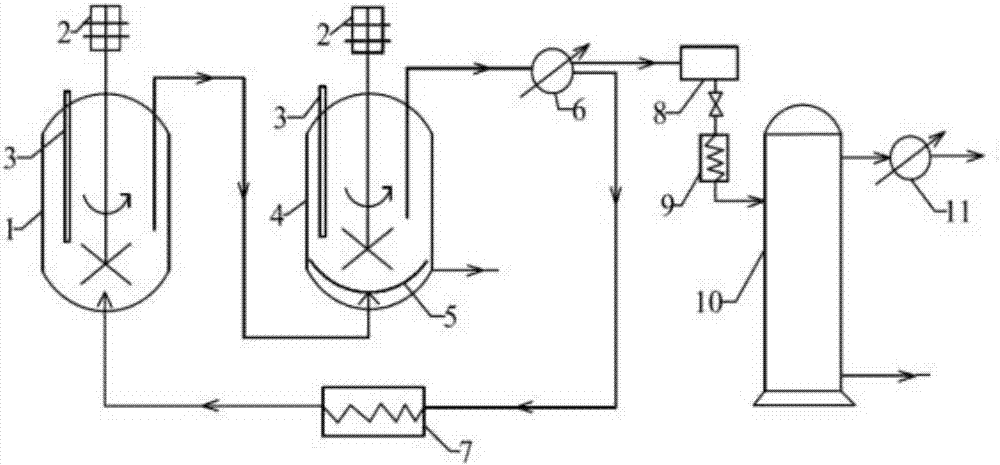

[0037] Step 1, according to figure 1 In the process shown, first add 2mol / L sulfuric acid catalyst solution into the dehydration reactor 1, and pass nitrogen gas at 150°C to 200°C at the bottom of the dehydration reactor 1, heat the catalyst solution to reflux, and then add a cocatalyst to chlorinate Sodium, the quality of sodium chloride is 25% of sulfuric acid solution quality, stirs to form a rotating liquid level with fixed catalyst concentration, and this nitrogen is heated through nitrogen heater 7.

[0038] Step 2. Add the 10wt% xylose solution obtained by hydrolysis of hemicellulose dropwise into the reactor at 2ml / min to 5ml / min, heat the reaction at a constant temperature with nitrogen, carry out dehydration reaction of xylose on the liquid surface layer, and generate furfural vapor Escape together with nitrogen.

[0039] Step 3: Add 5 wt% sodium sulfate solution as a neutralizing agent into the neutralization reactor 4, and set the temperature of the neutralization...

Embodiment 2

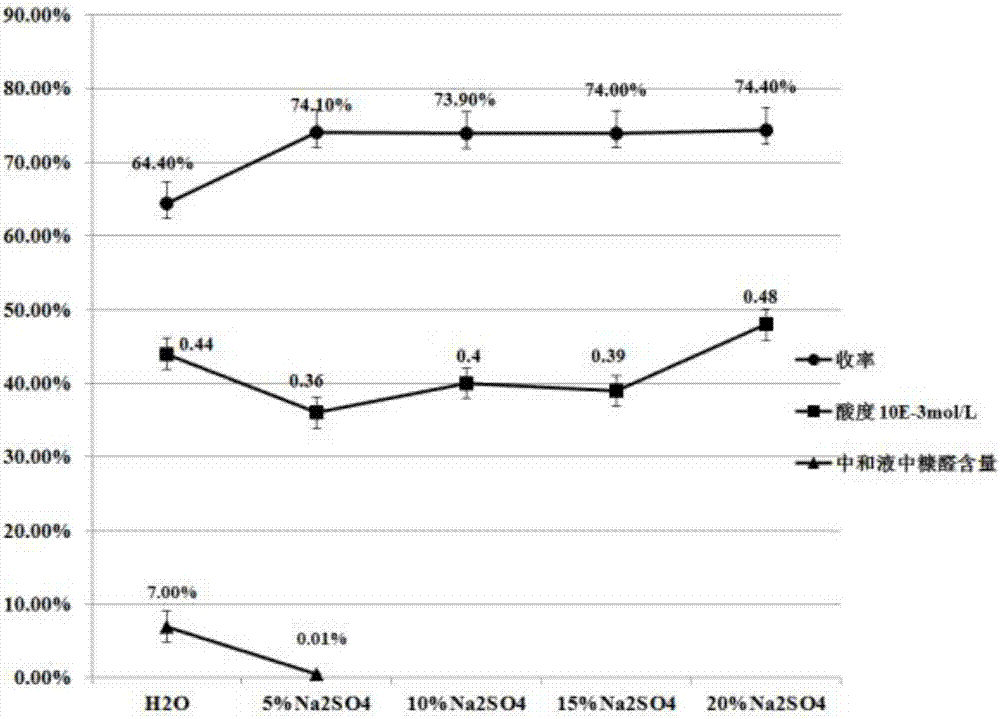

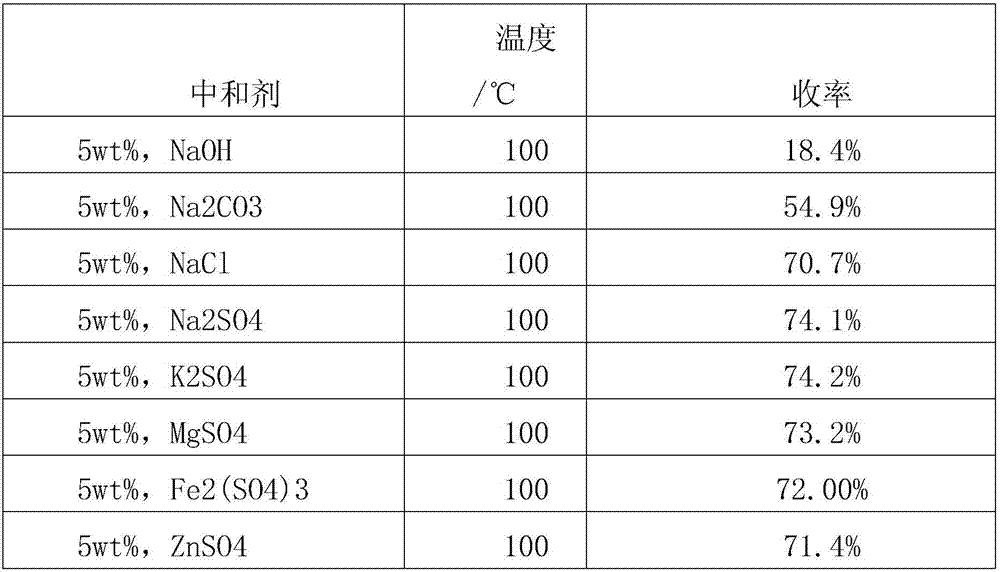

[0043] Embodiment 2: the concentration of changing sodium sulfate solution is respectively 10wt%, 15wt%, 20wt%, other conditions are identical with embodiment 1, and the furfural liquid acidity that obtains is respectively 4.0 * 10 -4 mol / L, 3.9×10 -4 mol / L, 4.8×10 -4 mol / L, furfural yields were 73.9%, 74.0%, 74.4%, and the pH values of neutralizers were 0.58, 0.62, 0.54.

[0044] Depend on figure 2 Known, the yield of furfural after the neutralization of inorganic salt solution is obviously higher than the furfural yield of neutralization in water, and after neutralization in water, the content of furfural in the neutralization liquid is 7% (accounting for the percentage of theoretical furfural mass), sodium sulfate neutralization The furfural content in the liquid is very little about 0.01%, which shows that some furfural is dissolved after the aldehyde vapor enters the aqueous solution.

[0045] According to the electrostatic field theory, there is an electric field a...

Embodiment 3

[0046] Embodiment 3: adopt sodium chloride solution as neutralizing agent, other conditions are identical with embodiment 1, and the furfural liquid acidity that obtains is 2.2 * 10 -4 mol / L, the furfural yield is 70.7%, and the pH value of the neutralizer is 0.77.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com