Full-biodegradable dental floss pick handle and preparation method thereof

A dental floss stick, all-biological technology, applied in the field of oral care, can solve problems such as non-degradation, environmental pollution, etc., and achieve the effects of low equipment requirements, simple process flow, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Correspondingly, the embodiment of the present invention also provides a method for preparing the handle of a fully biodegradable dental floss stick as described above, including the following steps:

[0046] According to parts by mass, polyglycolic acid, toughening agent, nucleating agent, lubricant, compatibilizer and antibacterial agent, and optional components are blended to obtain a material;

[0047] The material is extruded and injected to obtain a fully biodegradable dental floss handle.

[0048] The embodiment of the present invention weighs polyglycolic acid, toughening agent, lubricant, compatibilizer, nucleating agent, filler, antibacterial agent and other raw material components according to a certain proportion, puts them into the mixing equipment, and mixes them evenly to obtain the material (also known as blends); the content of the proportion of each component, type selection and other content as mentioned above.

[0049] In the embodiment of the prese...

Embodiment 1

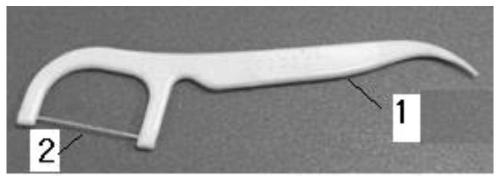

[0058] Press 85 parts of PGA, 10 parts of PBAT, 1 part of PE wax, 3 parts of talcum powder, 0.5 part of silver ion antibacterial agent, the mass ratio of 0.5 part of KH550, put the raw material components into the mixing equipment and carry out blending, the obtained blend The mixed material is prepared by a twin-screw extruder to obtain a special material for the handle, and the melt extrusion temperature is 220-250 °C; then, the obtained special material is prepared by an injection molding process to obtain a handle of a fully biodegradable dental floss stick; the injection molding melting temperature is 220-250 °C ℃, the mold temperature is 50-80℃, and the product structure is as follows figure 1 Middle handle 1.

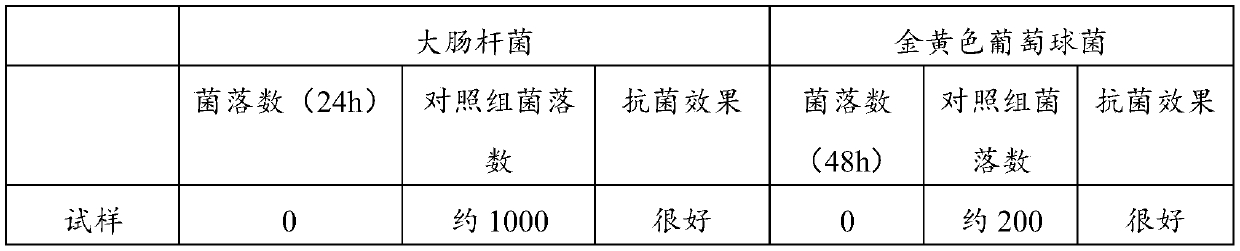

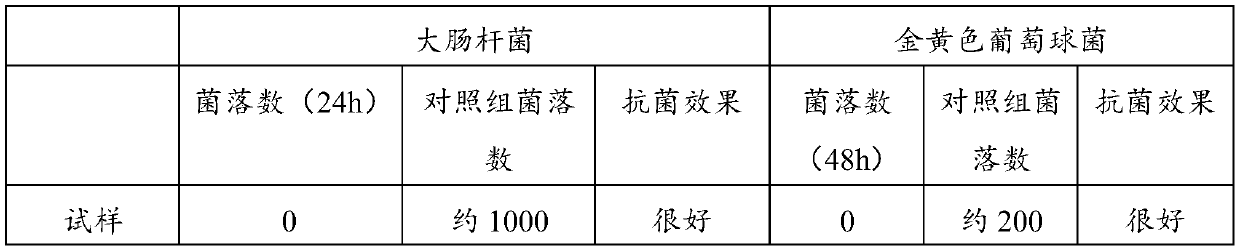

[0059] In addition, the special material was made into a standard sample, and the performance test was carried out. The mechanical performance results were as follows: the tensile strength was 76MPa, and the elongation at break was 94%. The antibacterial propert...

Embodiment 2

[0063] According to 70 parts of PGA, 12 parts of PCL, 15 parts of starch, 1 part of silicon dioxide, 1 part of EBS, 0.5 parts of silver ion antibacterial agent, and 0.5 parts of KH550 by mass, the raw material components are put into the mixing equipment for blending, The obtained blend is prepared through a twin-screw extruder to obtain a handle special material, and the melt extrusion temperature is 220-250°C; then, the obtained special material is prepared through an injection molding process to obtain a handle of a fully biodegradable dental floss stick; injection molding melts The temperature is 220-250°C, the mold temperature is 50-80°C, and the product structure is as follows figure 1 Middle handle 1.

[0064] In addition, the special material was made into a standard sample, and the performance test was carried out. The results of the mechanical properties were as follows: the tensile strength was 47MPa, and the elongation at break was 82%. The antibacterial effect is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com