High strength seamless steel pipe with excellent low temperature toughness and manufacturing method thereof

A seamless steel pipe, low temperature toughness technology, applied in the field of low alloy steel manufacturing, can solve the problems of structure, performance fluctuation, difficult control of manufacturing process, steel strength can not reach 100ksi, etc., to achieve easy realization, simple manufacturing process, stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

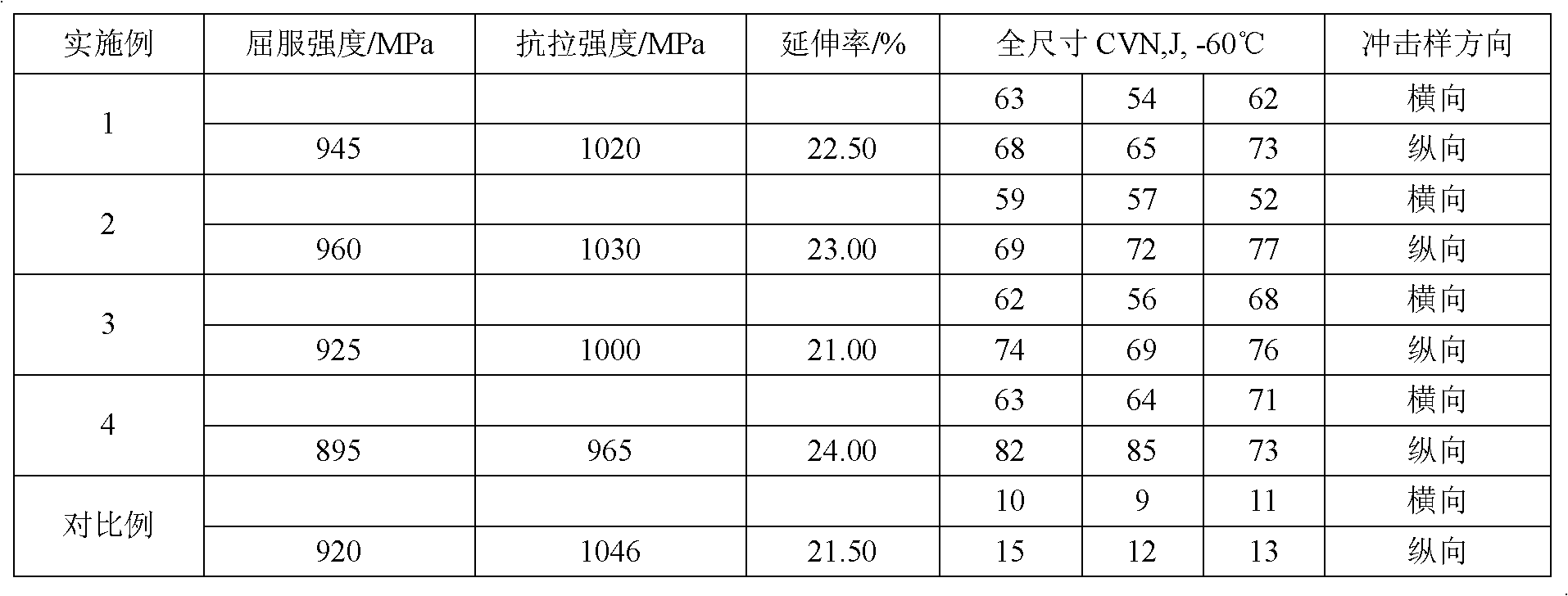

Examples

Embodiment Construction

[0037] Below by embodiment the present invention will be further described.

[0038] Adopt pure steel smelting process of hot metal pretreatment + converter smelting + LF refining + VD vacuum degassing, hot metal sulfur ≤ 0.0012%.

[0039] Carry out protective casting with electromagnetic stirring on molten steel with the composition in Table 1, and continuously cast it into a 280×380mm billet. During casting, control the superheat to less than 30°C, control the electromagnetic stirring current to be greater than or equal to 500A, and control the casting speed fluctuation range Within 0.05m / min, control the tension leveling temperature not lower than 950°C. After the continuous casting billet comes off the production line, it enters the soaking furnace for heating and heat preservation at 1300-1340 ℃, and then it is rolled into a round tube billet with a size of φ210 through rough rolling and finishing rolling. It can also be rolled into a φ200, Different sizes such as φ185. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com