Tailing-based cementing material and preparation method thereof

A technology of tailings and rubber base, which is applied in cement production and other directions, and can solve the problem of low utilization of tailings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing a tailings-based environmental functional material, the specific implementation steps are as follows:

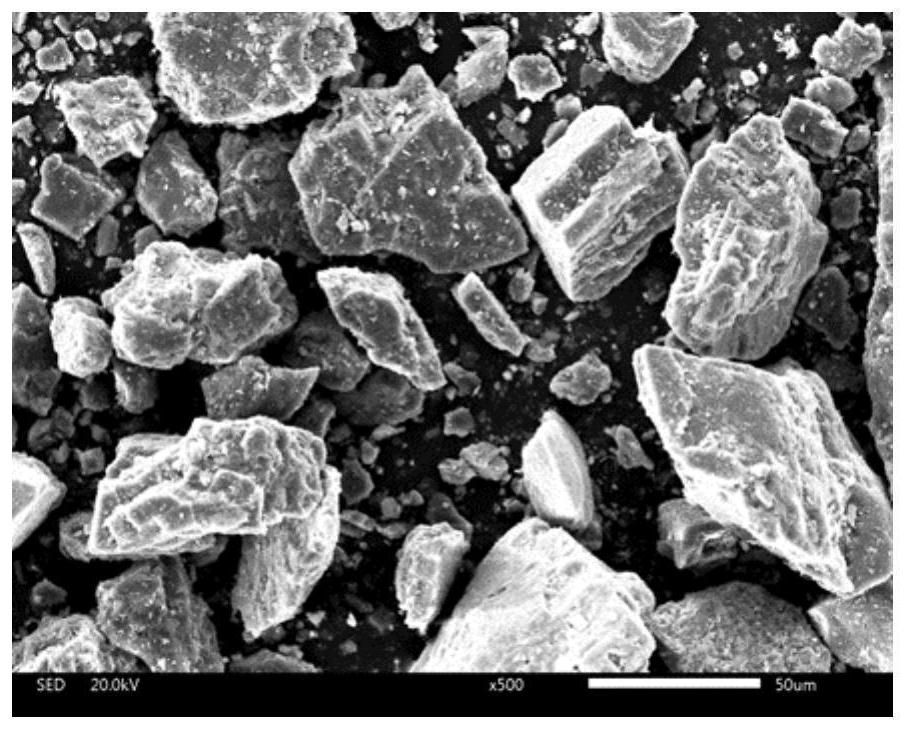

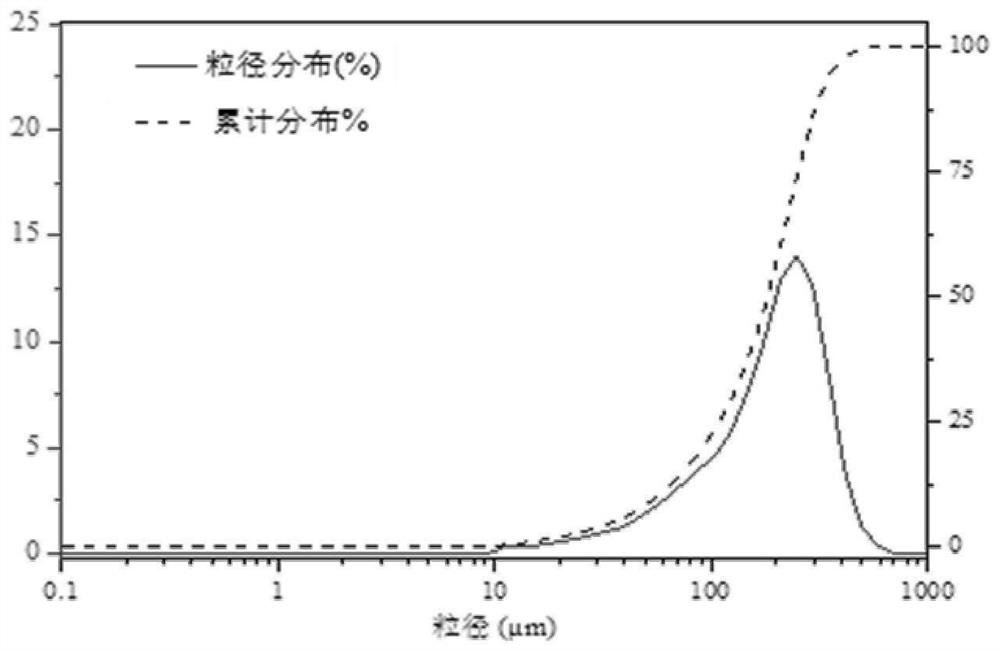

[0036]1) Take 10kg of lead-zinc tailings (the total mass of quartz and dolomite accounts for about 70%, and the original D of lead-zinc tailings 50 At about 150 μm, with a moisture content of about 20%), put it into a blast drying oven at 105°C and dry it to constant weight, then use a ball mill (rotating speed: 300r / s) to grind the dried lead-zinc tailings for 120min and save it for later use;

[0037] 2) Add rice husk ash accounting for 0% to the lead-zinc tailings obtained in step 1), mix well and set aside;

[0038] 3) The product obtained in step 2) is placed in a heating device and heated at 500°C for 40 minutes, and then cooled naturally for later use;

[0039] 4) Add sodium sulfate accounting for 10% to the product obtained in step 3), mix well and set aside;

[0040] 5) The product obtained in step 4) was subjected to a clean pulp for...

Embodiment 2

[0049] A preparation method of tailings-based cementitious material, the specific implementation steps are as follows:

[0050] 1) Take 10kg of lead-zinc tailings (the total mass of quartz and dolomite accounts for about 70%, and the original D of lead-zinc tailings 50 At about 150 μm, moisture content at about 20%), put it into a blast drying oven at 105°C and dry it to constant weight, then use a ball mill (ball milling speed is 200r / s) to grind the dried lead-zinc tailings for 20 minutes and save it for later use;

[0051] 2) Add rice husk ash accounting for 30% to the lead-zinc tailings obtained in step 1), mix well and set aside;

[0052] 3) The product obtained in step 2) is placed in a heating device and heated at 400°C for 30 minutes, and then cooled naturally for later use;

[0053] 4) Add cement clinker accounting for 8% to the product obtained in step 3), mix well and set aside;

[0054] 5) The product obtained in step 4) was subjected to a clean pulp forming expe...

Embodiment 3

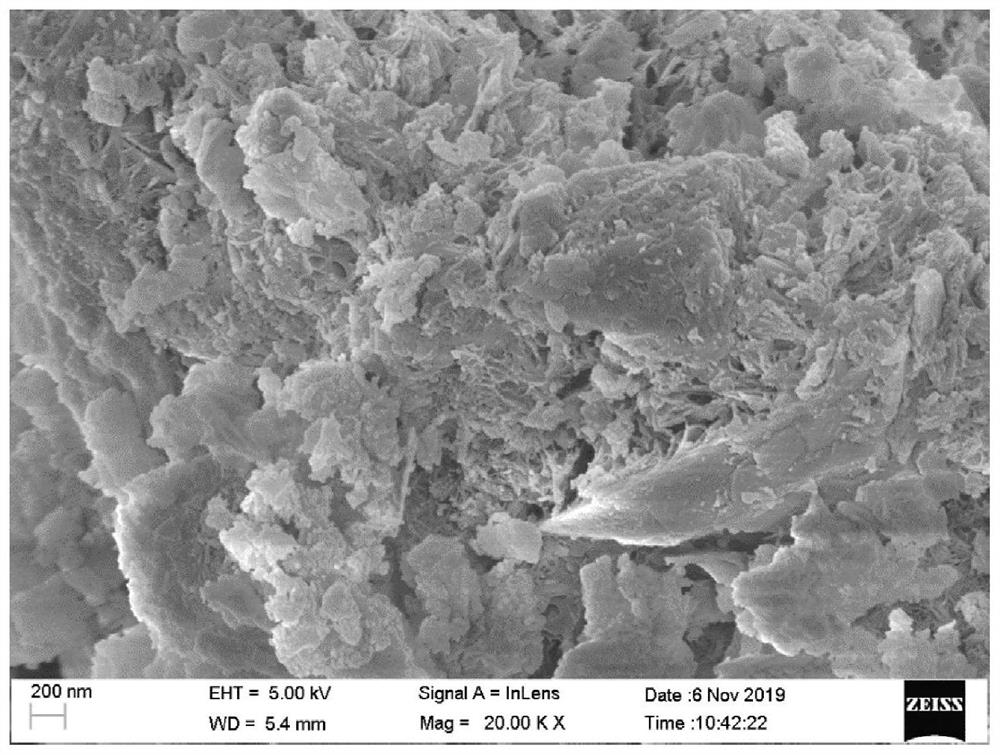

[0057] 1) The consolidated body consolidated for 28 days in the implementation case 1 is broken, and sealed with absolute alcohol for 2 days;

[0058] 2) Dry the solid in step 1) at 70°C, grind through a 5mm square hole sieve for later use;

[0059] 3) The solid in step 2) is tested for leaching toxicity using the standard HJ / T 300-2007;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com