Surface treatment apparatus and surface treatment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]The examples of the present invention will be described below.

[0051]The embodiments of the present invention will be described below referring to the drawings.

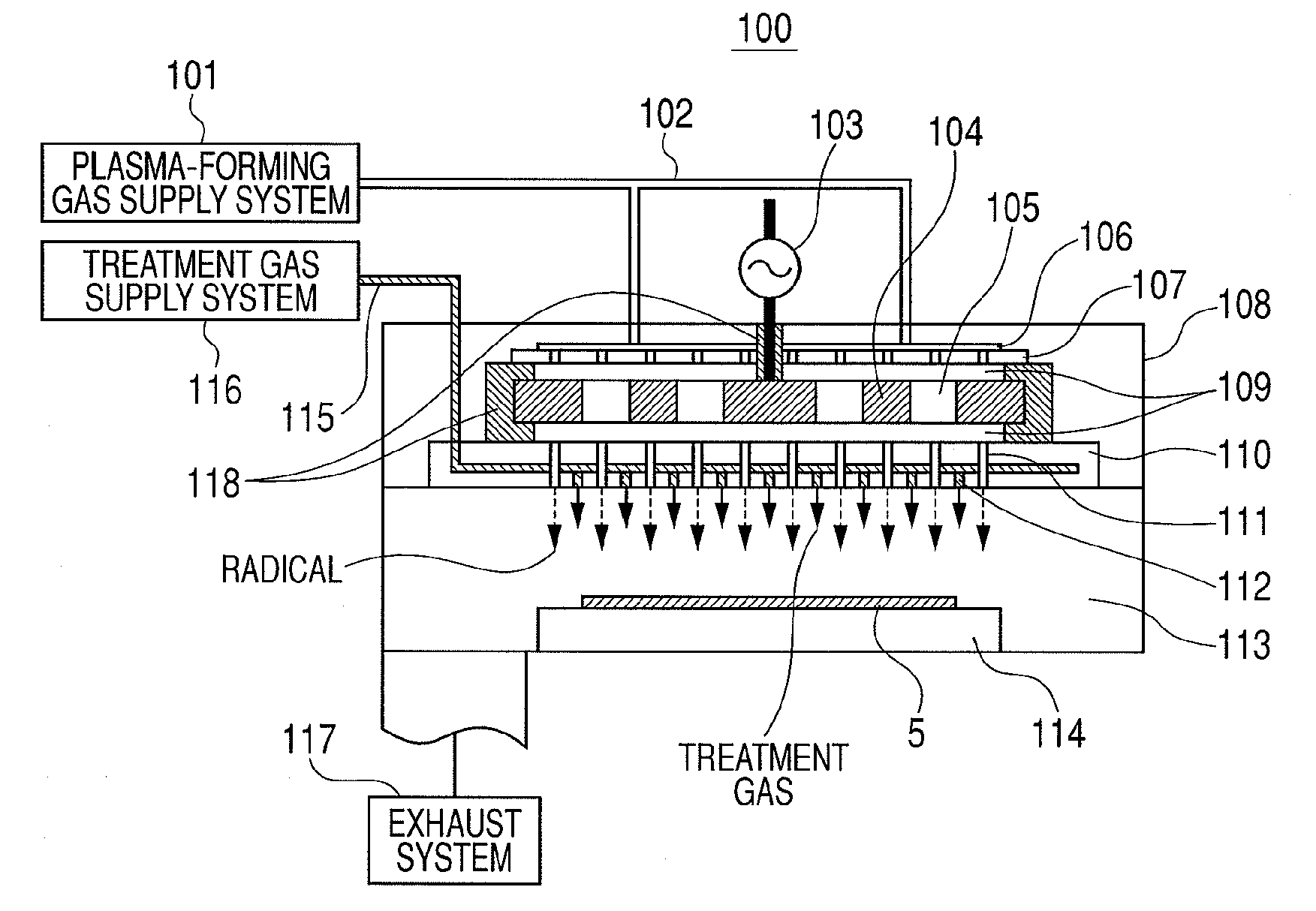

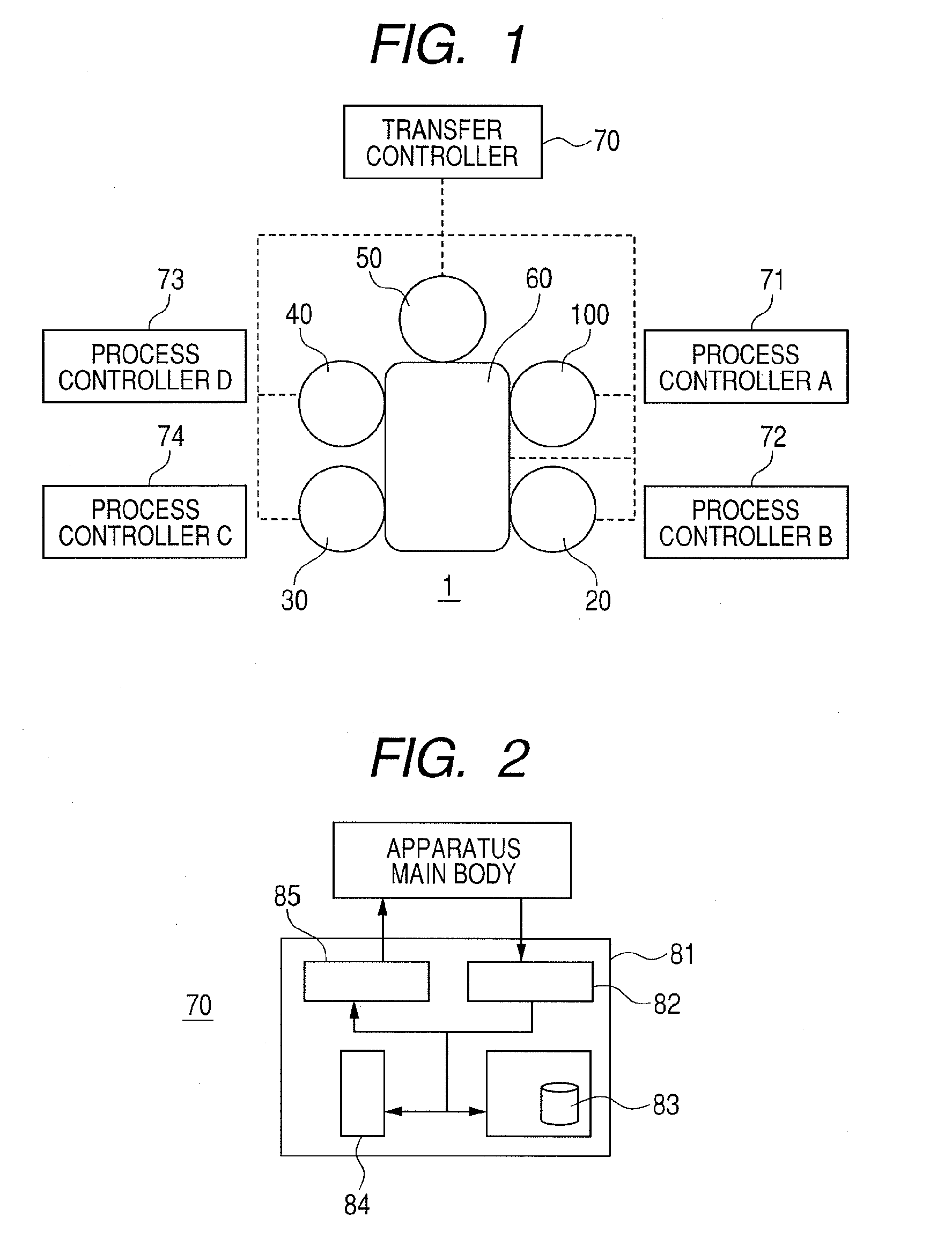

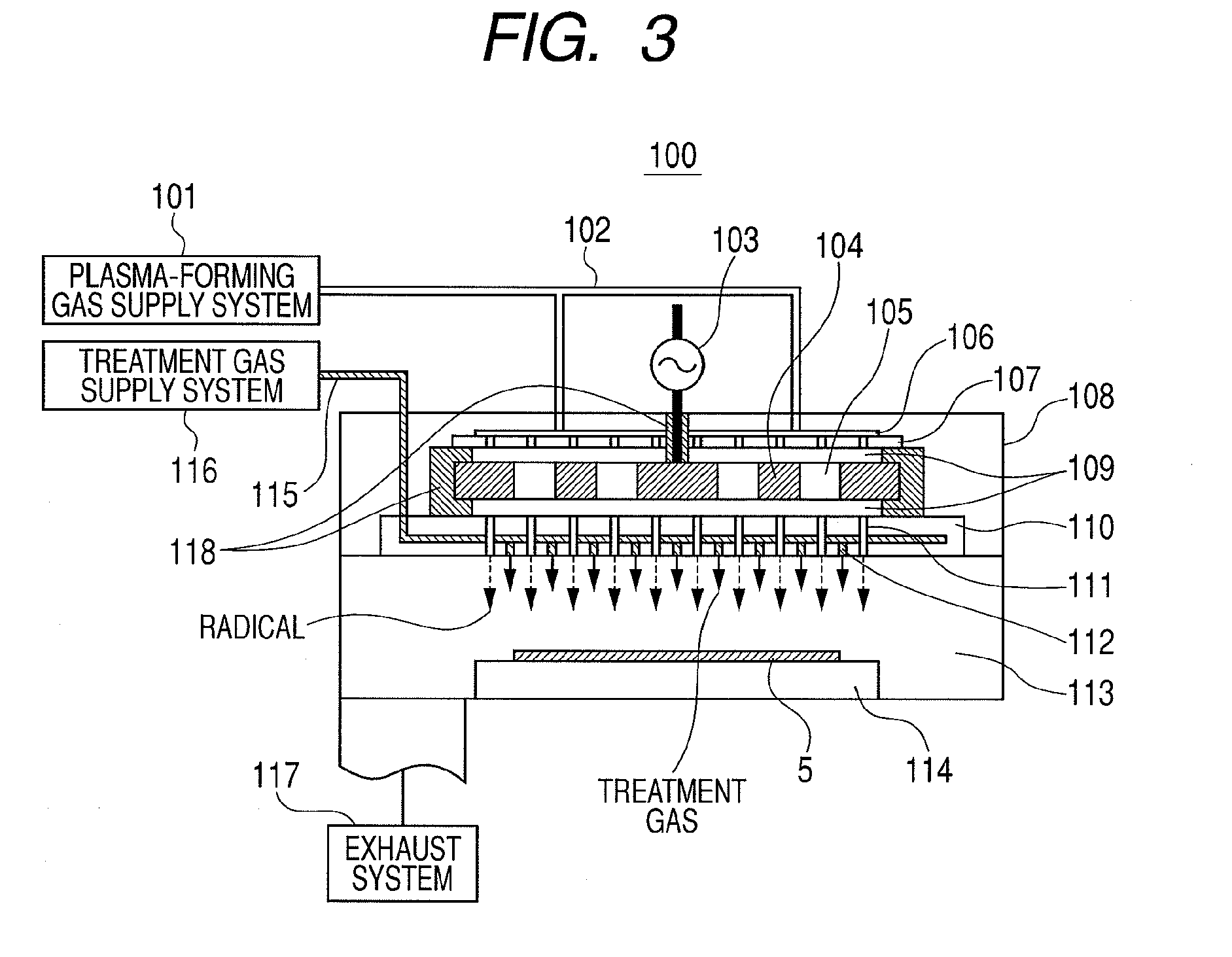

[0052]The examples deal with the cases of applying the present invention to a film-forming apparatus 1 illustrated in FIG. 1, focusing on the process of removing native oxide film and organic matter formed on a Si substrate by the first step using a surface treatment apparatus 100 illustrated in FIG. 3.

[0053]A substrate 5 which is adopted as the sample is a Si single crystal substrate (with 300 mm in diameter) which is allowed to stand in a clean air to form a native oxide film thereon. The substrate 5 is transferred to a load-lock chamber 50 by a substrate transfer mechanism (not shown) to be placed therein. Then, the load-lock chamber 50 is evacuated by an evacuation system (not shown). After evacuating to a desired pressure, or 1 Pa or below, a gate valve (not shown) between the load-lock chamber and the transfer cham...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Dielectric polarization enthalpy | aaaaa | aaaaa |

| Surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com