Preparation and application of high strength acid 172 black liquid dye

A liquid dye, high-strength technology, applied in the direction of complex metal compounds, applications, azo dyes, etc. of azo dyes, can solve the problem of increasing waste water, can not effectively improve the water solubility, filtration performance and storage performance of acid 172 dyes, can not meet the High-speed one-pass printing and other issues to achieve high-strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Refining of 6-nitro-1-diazo-2-hydroxy-4-naphthalenesulfonic acid (also known as 6-nitrite):

[0063] In 3000 liters of PP material #1 reactor, 500Kg6-nitrox was added to 1000 liters of demineralized water, stirred and beaten at 180-200rpm, the temperature was controlled at 20°C and 120 liters of 30% NaOH solution was added to adjust the pH=1.03. After complete dissolution, filter with a cloth bag filter, collect the filtrate and transfer to #2 reaction kettle.

[0064] Add 230 kilograms of sodium chloride to #2 reactor within 1 hour, leave standstill after stirring. After the solid is no longer precipitated, filter with a plate and frame filter press to obtain a filter cake. Put this filter cake into #1 reactor, beat with 1000 liters of soft water, control the stirring speed 180-200rpm, control the temperature not to exceed 20°C all the time, then add 120Kg of 30% hydrochloric acid until the material is completely dissolved.

Embodiment 2

[0067] The refining of nitrox is different from Example 1 in that 125 liters of 30% NaOH solution is added in the initial stage to adjust the pH to 2. Other steps are the same as those in Implementation 1, and then the refined 6-nitrox wet filter is obtained. Cake 664Kg, converted to dry 288Kg, converted yield is 61.8%. The data before and after purification of the 6-nitrite measured by HPLC and ion chromatography are shown in Table 1 below.

Embodiment 3

[0069] The refining of 6-nitrite refining is different from Example 1 in that 125 liters of 30% NaOH solution is added at the initial stage to adjust the pH to 2, and the amount of sodium chloride added to the refining of the first step is increased to 265 kilograms, Other steps are all identical with implementation 1, then obtain refined 6-nitroxygen wet filter cake 737Kg, dry 345Kg, conversion yield is 69.0%. The data before and after purification of the 6-nitrite measured by HPLC and ion chromatography are shown in Table 1 below.

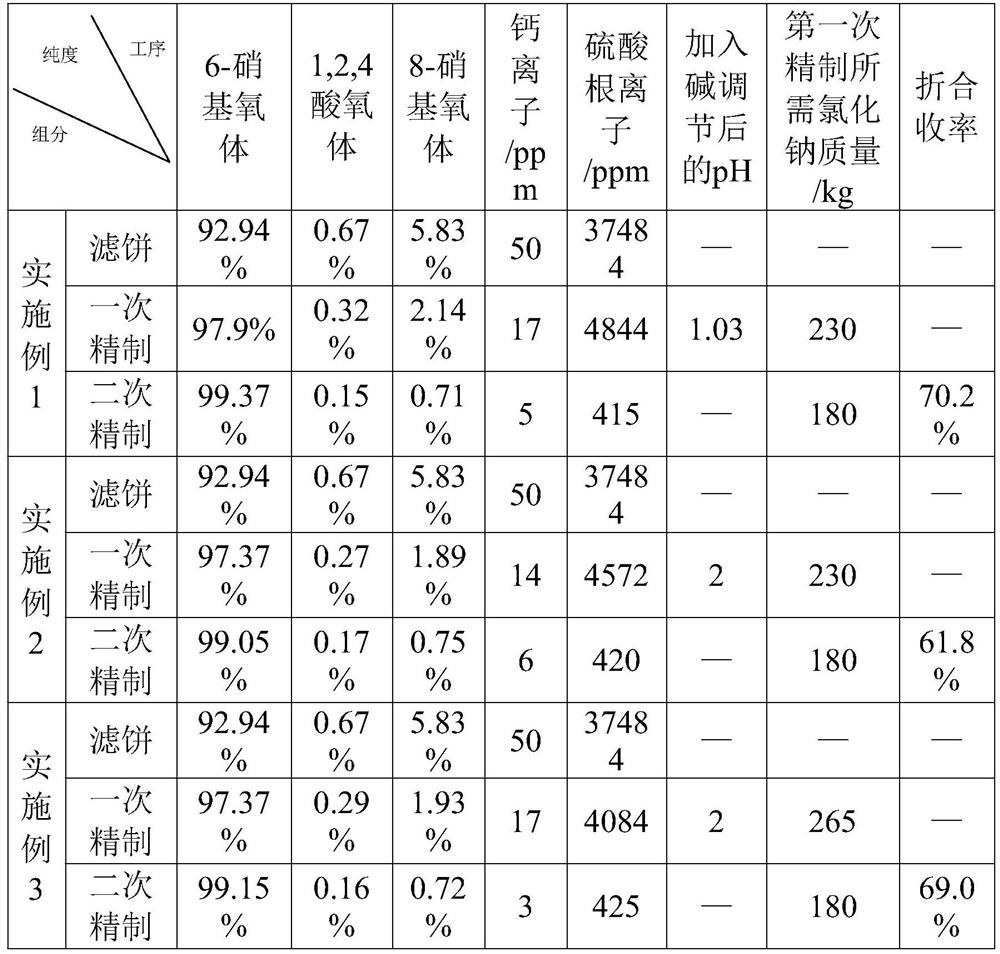

[0070] Table 1 Comparison table of data before and after refining 6-nitrox

[0071]

[0072] As can be clearly seen from the data in Table 1, when the pH was 1.03, the yield was higher, and the quality of sodium chloride added when the first step was refined was relatively less (embodiment 1); when the pH was raised to 2 , if add the sodium chloride of same quality, then productive rate has reduced nearly 10% (embodiment 2); If want to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com