Non-contact type power automatic feeding and paving device

An automatic supply and non-contact technology, which is applied in the field of non-contact powder automatic supply and leveling device, can solve the problems of the powder spreading device stuck and the powder spreading function not being realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The principle, structure and working process of the present invention will be described in detail below in conjunction with the accompanying drawings.

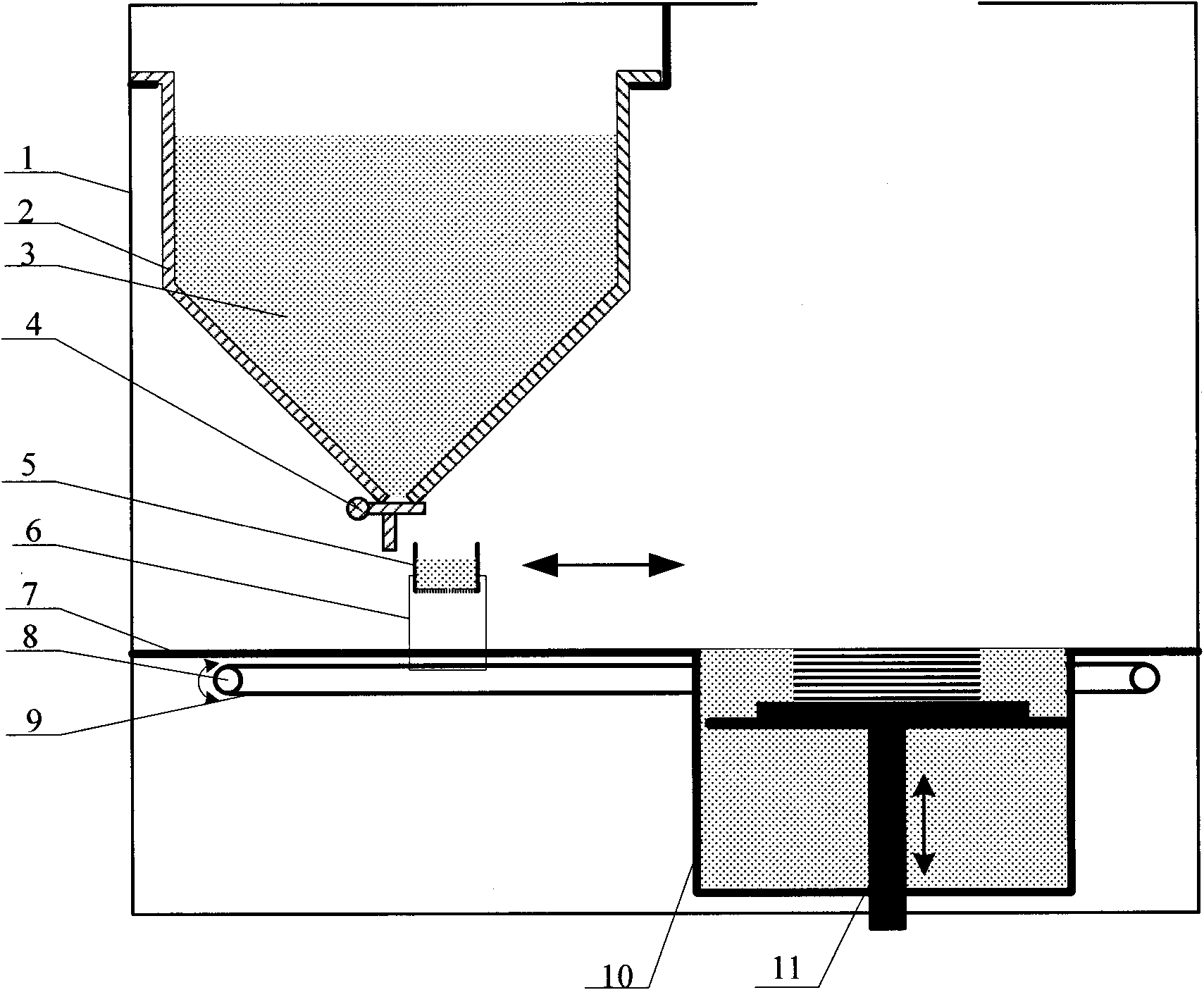

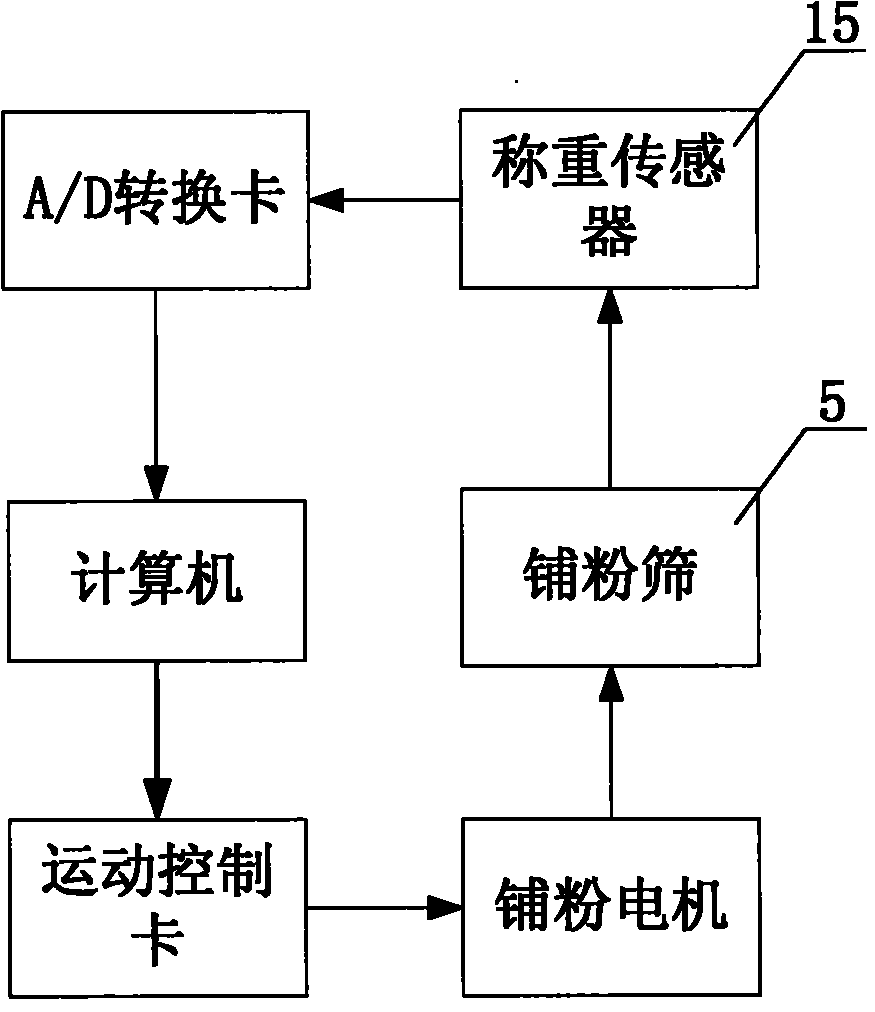

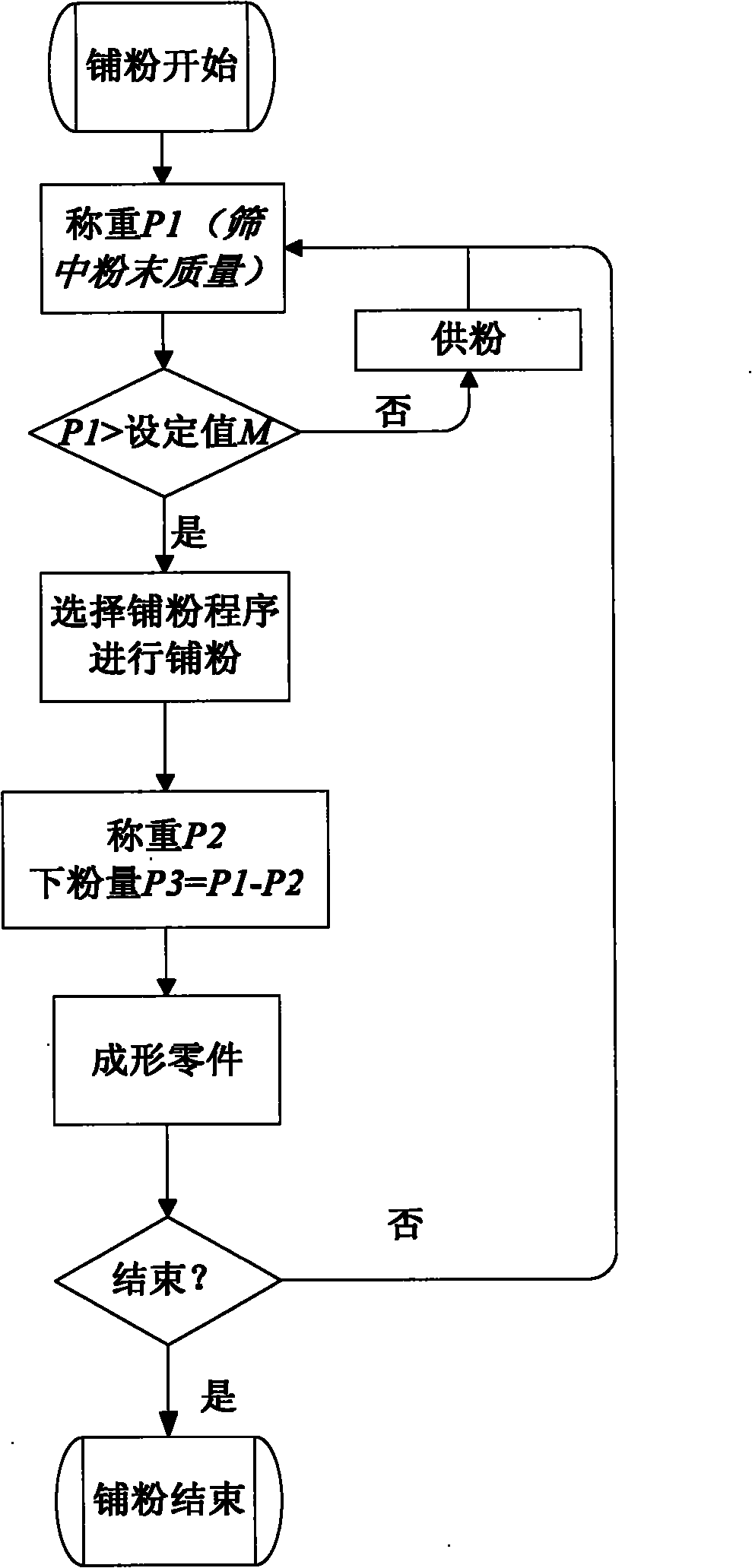

[0018] figure 1 It is a schematic diagram of the structure principle of the present invention. The device includes a working chamber 1, a material box 2 with powder 3, a stopper 4 arranged at the bottom of the material box, a powder spreading system, a working platform 7 with a limit stroke switch, and a workpiece chamber 10 with a piston 11; The material box 2 is fixed in the working chamber 1, the working platform 7 is placed under the material box 2, and the workpiece cavity 10 is fixed on the working platform 7. The powder spreading system is composed of a powder spreading sieve 5, a connecting piece 6, a load cell 15 and a driving device; the powder spreading sieve 5 is suspended above the working platform 7 and below the material box 2 through the connecting piece 6; the driving device consists of Powder spreadi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com