Nitride semiconductor laser device and method for fabrication thereof

a laser device and semiconductor technology, applied in the direction of lasers, semiconductor laser structural details, semiconductor lasers, etc., can solve the problems of difficult fabrication of nitride semiconductor light-emitting devices, and achieve the effects of reducing film thickness, preventing cracks, and good surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

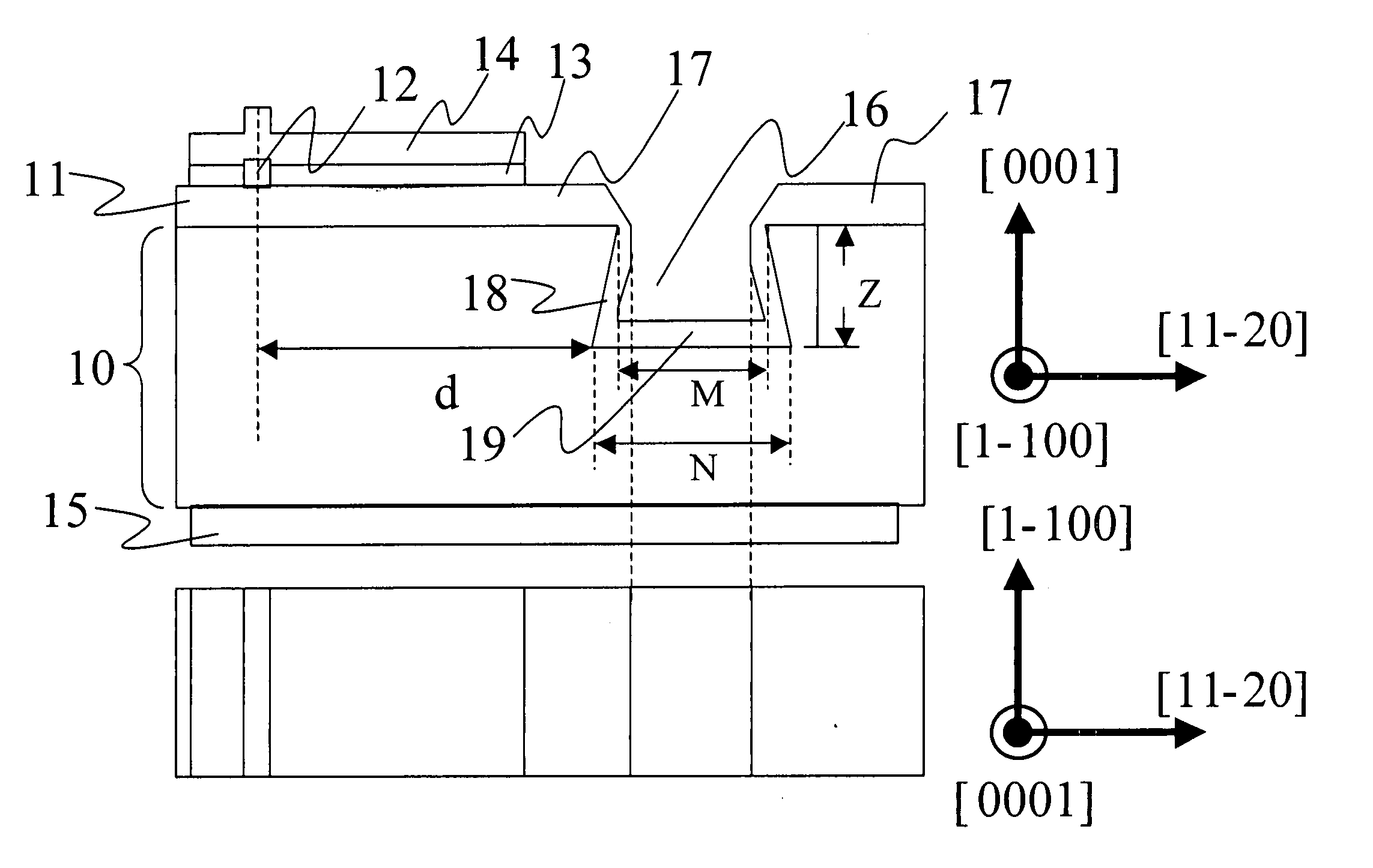

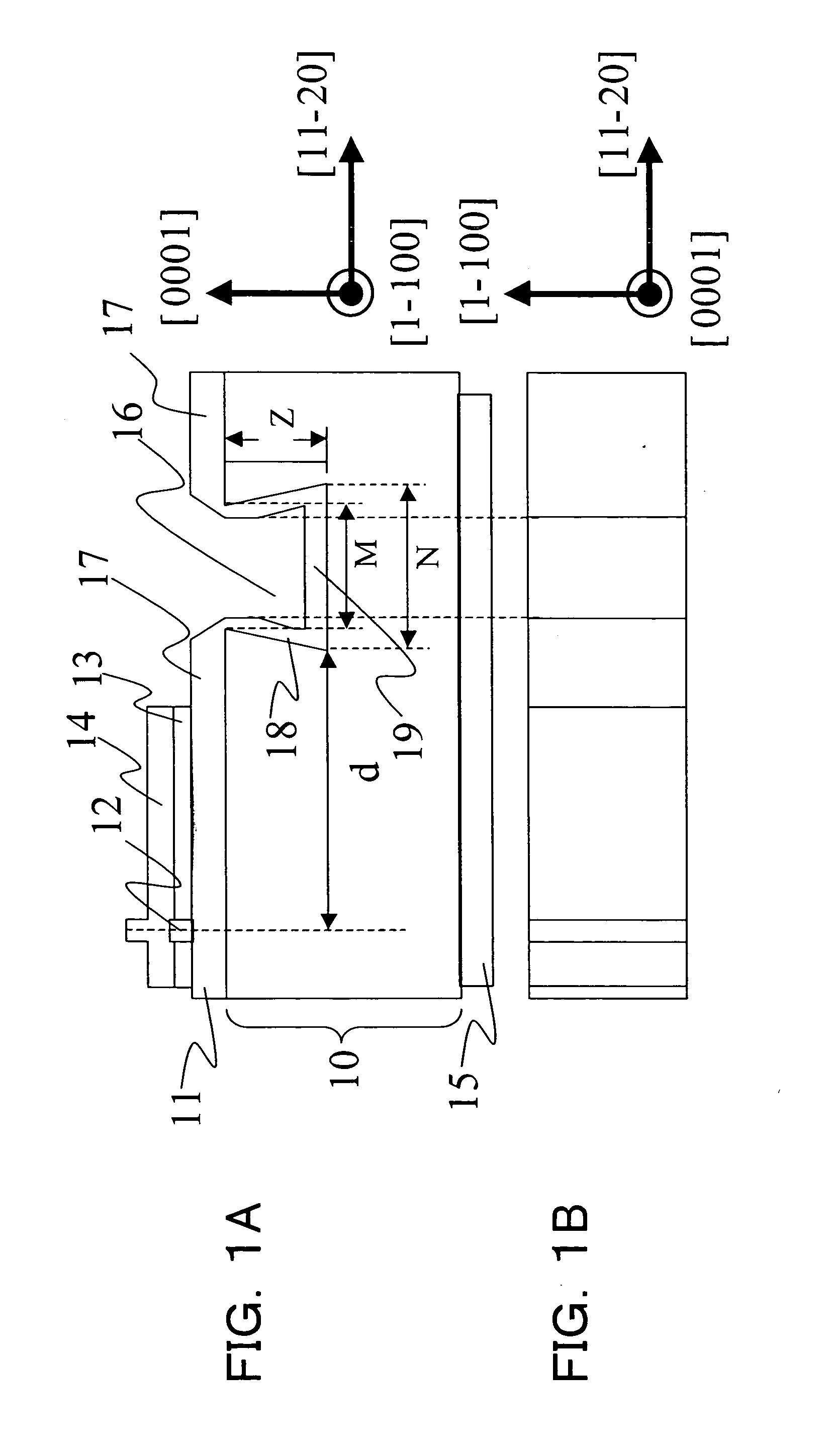

[0065]FIG. 1A is a schematic sectional view of a nitride semiconductor laser device embodying the invention, and FIG. 1B is a top view of FIG. 1A. FIG. 3B is a schematic sectional view of a GaN substrate before a nitride semiconductor layer is grown on top thereof in the embodiment of the invention, and FIG. 3A is a top view of FIG. 3B. In these diagrams, the surface orientations are also indicated.

[0066] The nitride semiconductor laser device shown in FIGS. 1A and 1B is produced by laying or otherwise forming a nitride semiconductor growth layer on top of the GaN substrate shown in FIGS. 3A and 3B.

[0067] In the following descriptions, a “nitride semiconductor substrate” is formed from AlxGayInzN (where 0≦x≦1, 0≦y≦1, 0≦z≦1, and x+y+z=1). So long as the nitride semiconductor substrate has a hexagonal crystal structure, about 10% or less of the nitrogen contained t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com