Building wall surface flatness measuring device

A measuring device and flatness technology, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of poor overall adaptability and achieve the effects of detection, convenient operation and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

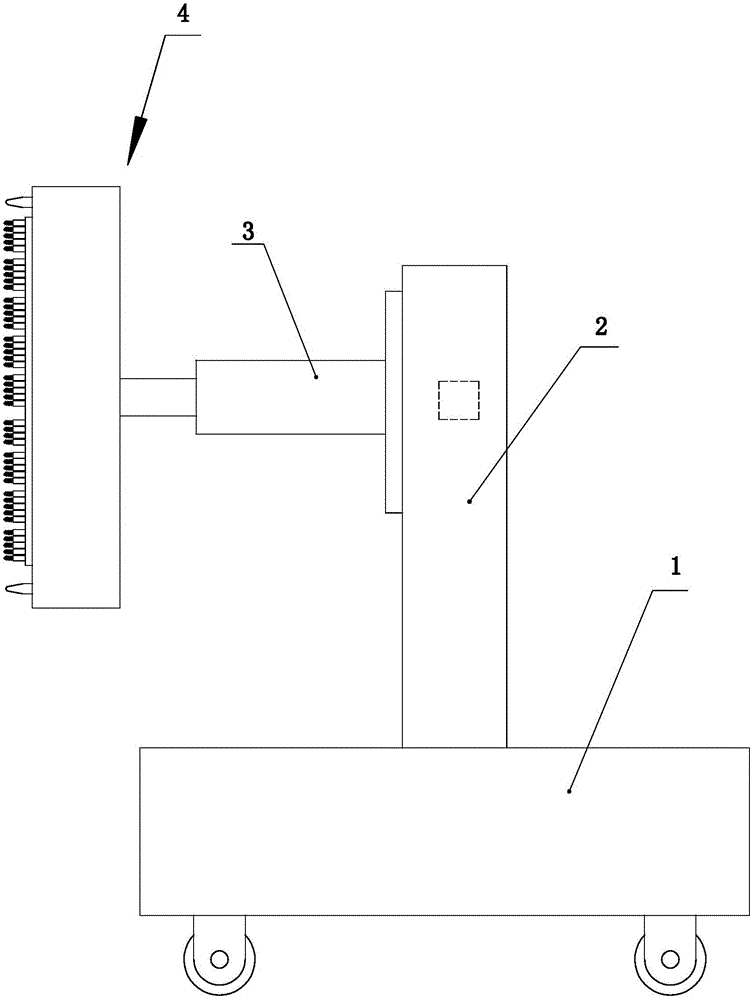

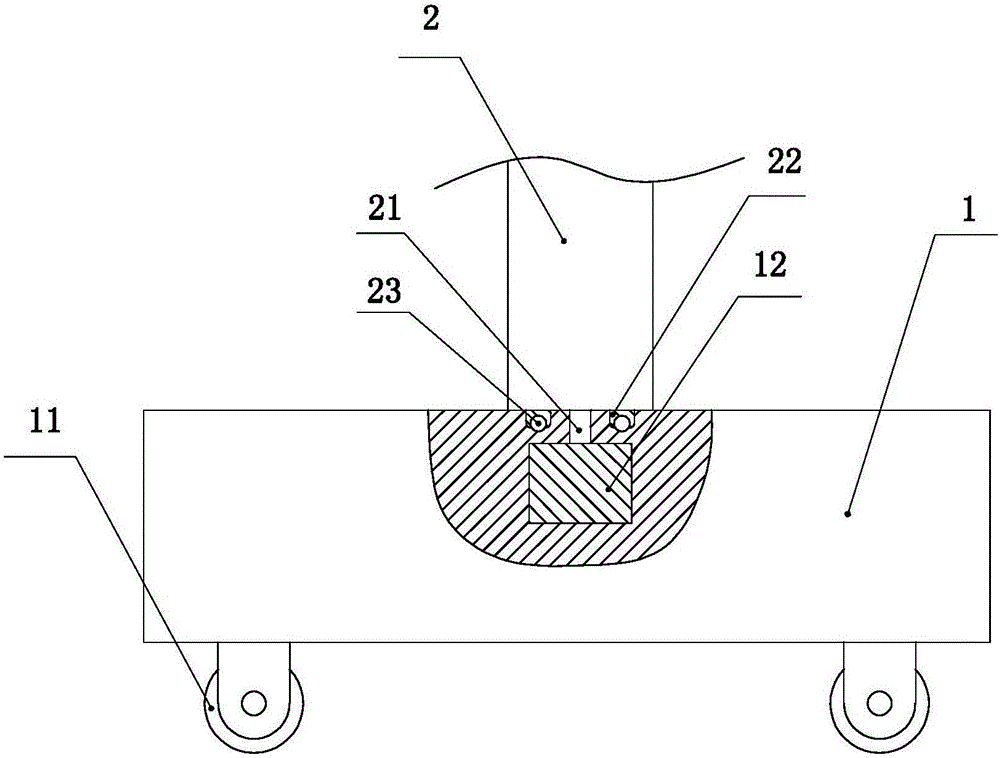

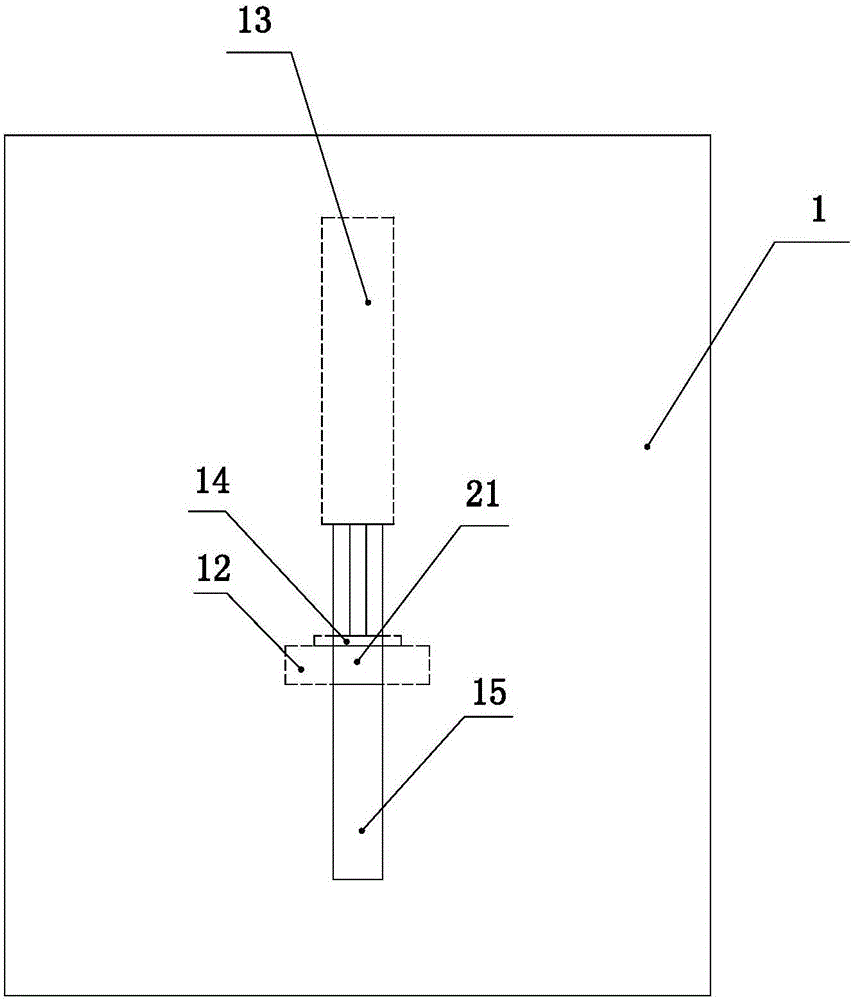

[0036] like figure 1 , figure 2 As shown, the car body 1 is the basic component of the present invention, the bottom of the car body is provided with traveling wheels 11, the top of the car body is provided with a vertical beam 2, the bottom of the vertical beam is fixed with a fixed block 22, and the inner cavity of the fixed block A ball 23 that can rotate 360 degrees is provided in the middle, and a part of the ball protrudes from the bottom of the fixed block, and a long groove adapted to the shape of the fixed block is provided on the top of the car body, and the ball is in contact with the bottom of the long groove, The sliding connection between the vertical beam and the car body is realized by the fixed block and the ball. A chute is provided in the car body, and a slide block 12 is slidably installed in the chute, such as ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com