Centrifugal shot blasting electroforming manufacturing method and device

A technology for manufacturing devices and manufacturing methods, which is applied in the field of centrifugal shot peening electroforming manufacturing methods and devices, which can solve the problems of uneven materials, even delamination, and mechanical performance degradation of parts on the upper and lower layers of the deposition layer, so as to improve the deposition speed of electroforming , Inhibition of build-up and pits, and improvement of fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

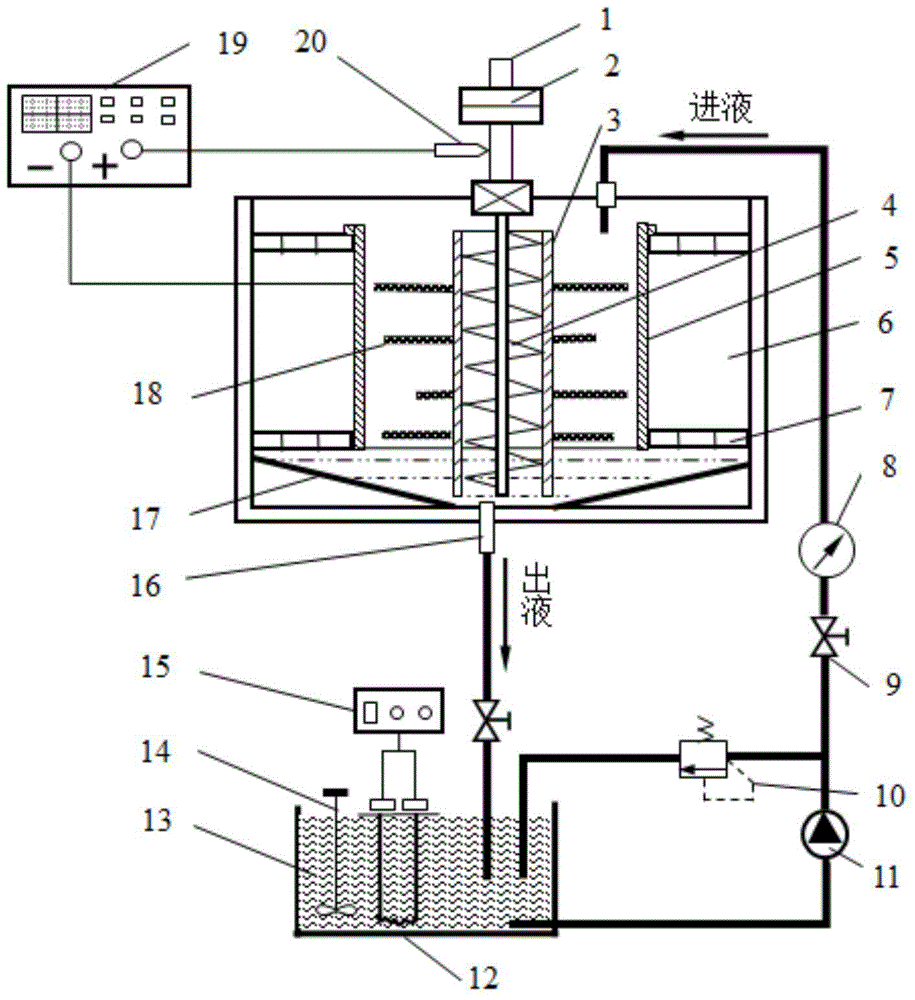

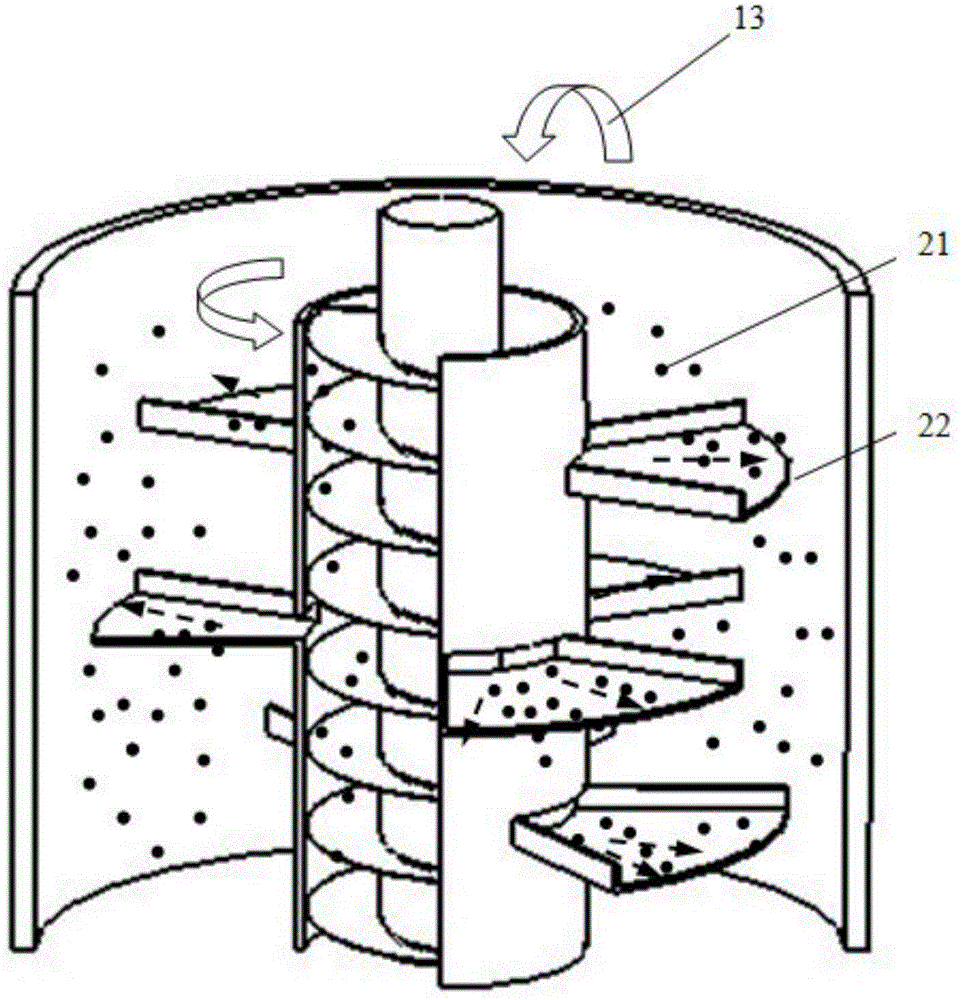

[0028] like figure 1 , figure 2 As shown, the centrifugal shot peening electroforming manufacturing device of the present invention is mainly composed of an electroforming tank 6, a centrifugal rotating system, an electrodeposition system and a solution circulation system; the solution circulation system includes a liquid storage tank 12, a magnetic pump 11. Ball valve 9, overflow valve 10, electroforming tank 6, collecting plate 17 and screw lifter 4, the inner wall of the electroforming tank 6 is provided with a bottom plate 7, and the collecting plate 17 is obliquely fixed on the bottom of the electroforming tank 6 A circulation pipeline is arranged between the liquid storage tank 12 and the electroforming tank 6, the magnetic pump 11, the pressure gauge 8, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com