Automobile main carpet with anti-skid function and manufacturing method thereof

A production method and automobile technology, which are applied in the field of automobile carpets, can solve the problems of unenvironmental protection in the preparation process and complicated processes, and achieve the effects of reducing the increased risk and having strong wear-resistant and anti-skid effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] A method for making a main carpet for automobiles with an anti-skid function, the method specifically includes the following steps:

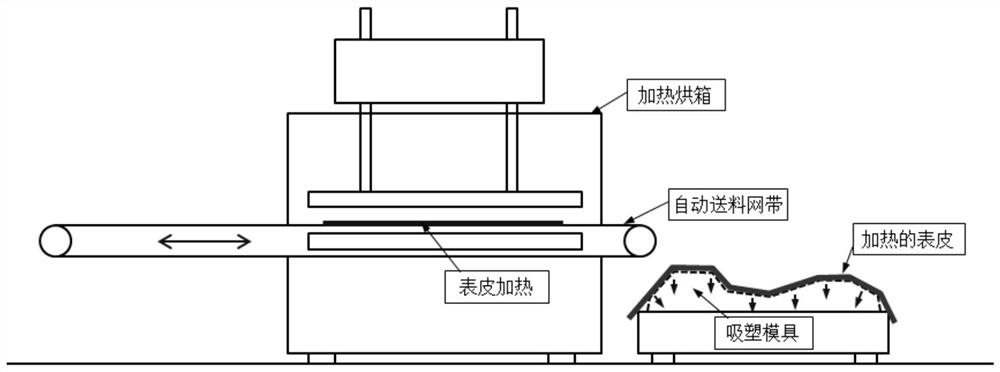

[0030] (1) Put the TPO epidermis and the EPDM epidermis into the oven for heating and softening, and then spread the two layers of skin after heating and softening on the blister mold, wherein the TPO epidermis is located on the side away from the blister mold; wherein, the heating temperature The temperature is (250±20)℃, and the time is (150±20)s;

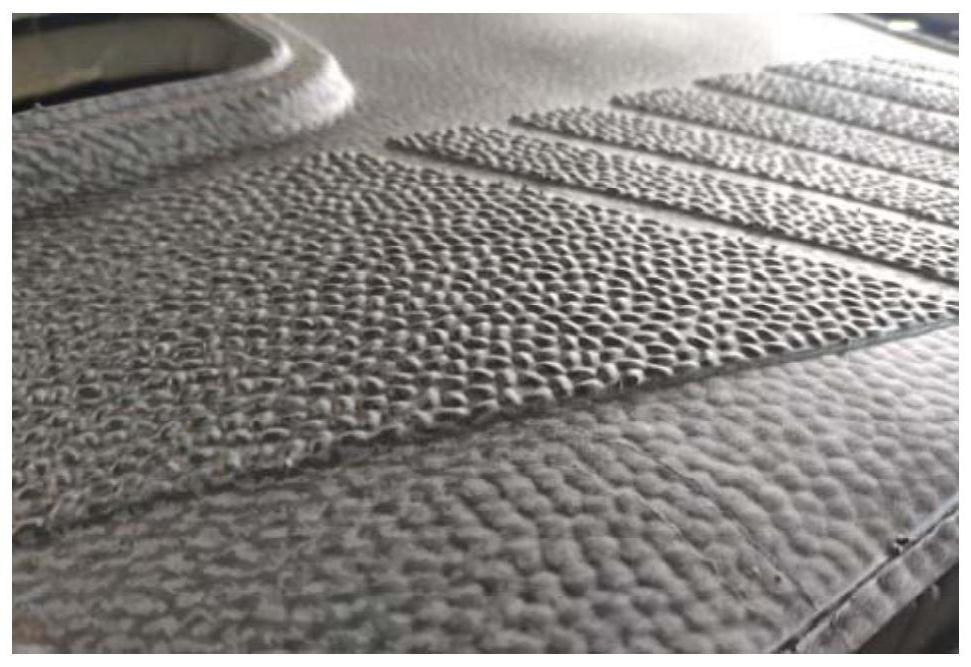

[0031] (2) Start the vacuum switch of the plastic-absorbing mold, and perform vacuum-absorbing molding on the softened two-layer skin to form a molded skin with skin texture on the surface; wherein, the vacuum-pumping value of the vacuum-absorbing molding is (0.08±0.02) MPa;

[0032] It should be noted that the skin material is a double-layer structure, the surface decoration layer is TPO + the back layer is EPDM, and the two are integrated. Put the skin upwards on the automatic feeding me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com