Light-cured 3D printing material supply fluid path system

A 3D printing and 3D printer technology, applied in the field of 3D printing, can solve problems such as difficult to realize, large-capacity material box and impractical movement of the printing head, and achieve low manufacturing cost, improved printing efficiency, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

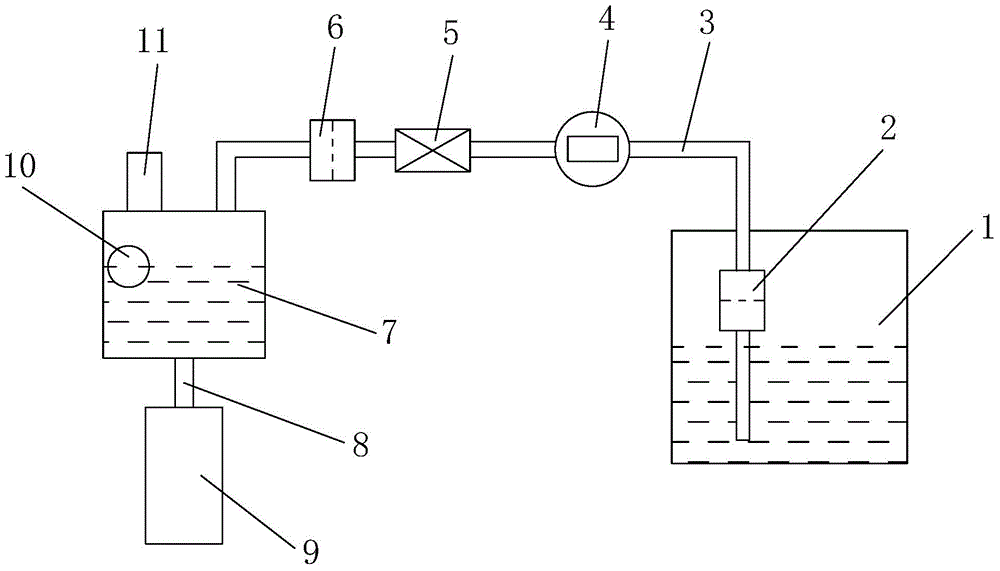

[0018] like figure 1 As shown, the present invention includes a main material box 1, a first filter 2, an infusion pipeline 3, a fluid pump 4, a solenoid valve 5, a second filter 6, an auxiliary material box 7, a hose 8, a liquid level sensor 10 and a negative Pressing device 11, the main material box 1 is arranged above the 3D printer casing and fixed on the 3D printer support frame, the auxiliary material box 7 is arranged on the print head 9 of the 3D printer, and the auxiliary material box 7 passes through The hose 8 is connected to the print head 9, the liquid level sensor 10 is arranged inside the auxiliary material box 7, the negative pressure device 11 is installed on the top of the auxiliary material box 7, and one end of the infusion pipeline 3 extends into the main material Inside the box 1 and communicated with the main material box 1, the other end of the infusion pipeline 3 is communicated with the auxiliary material box 7, the first filter 2, the fluid pump 4, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com