Prefabricated concrete member steam curing production line and steam curing method

A technology of prefabricated concrete and steam curing, which is applied in the direction of manufacturing tools, ceramic molding workshops, auxiliary molding equipment, etc., can solve the problems of reduced thermal efficiency, low actual strength, low design strength, and high cost, and achieve the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

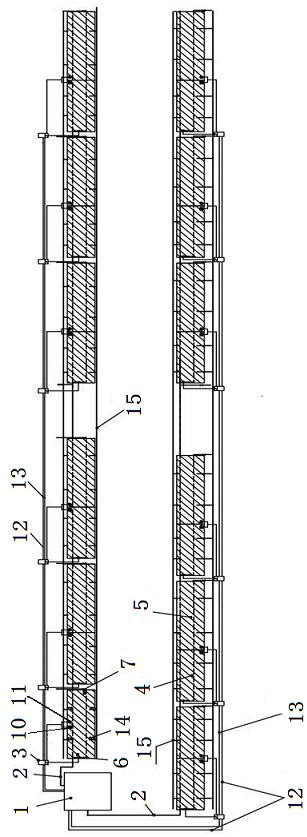

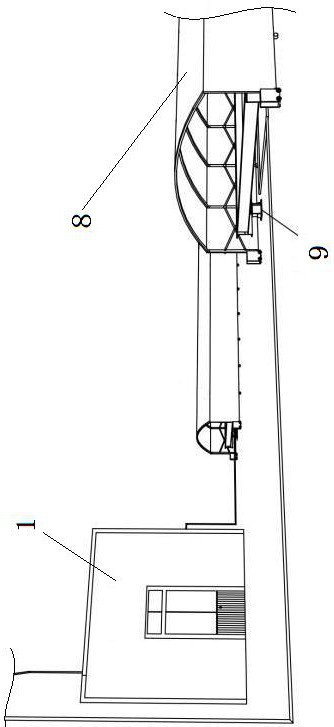

[0064] Such as figure 1 , figure 2 As shown, a steam curing production line for prefabricated concrete components includes a steam heat source machine room 1, a mold table, a steam delivery pipeline 2, and a steam curing shed 8.

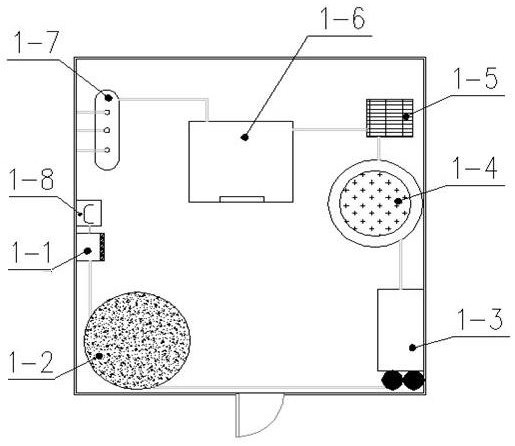

[0065] Such as image 3 As shown, the steam heat source machine room 1 is equipped with a main console 1-1, a water storage tank 1-2, a pure water machine 1-3, a water storage tank 1-4, a water supply pump 1-5, a steam heat source machine 1-6, Cylinders 1-7 and temperature and humidity automatic adjustment system 1-8, the main console 1-1 are respectively connected to water storage tank 1-2, steam heat source machine 1-6, feed water pump 1-5, temperature and humidity automatic adjustment system 1- 8. The water storage tank 1-2 is connected to the pure water machine 1-3, the pure water machine 1-3 is connected to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com