Electric power material supply whole-course early-warning supervise system and method

A power material, whole process technology, applied in the field of early warning and supervision system based on power material supply, can solve problems affecting the operation efficiency of power material supply chain, construction loss of power engineering projects, lack of active early warning mechanism, etc., to achieve rich functions and material supply. Timely and practical results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

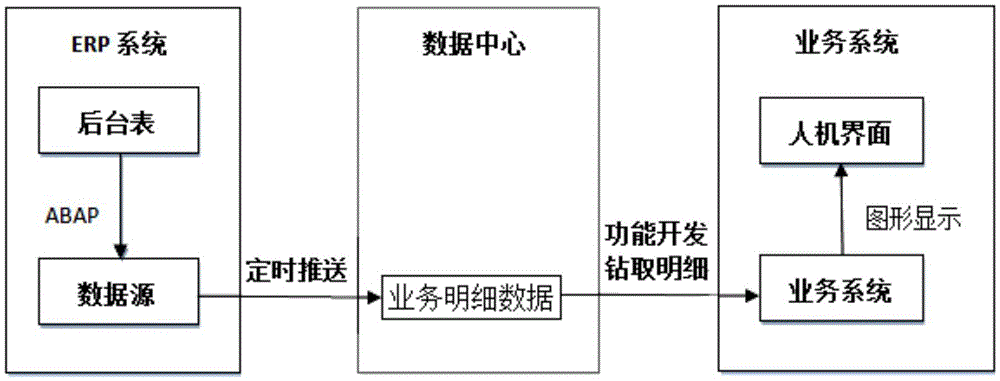

[0034] Such as figure 1 As shown, an implementation method based on the whole-process early warning and supervision of power material supply includes the following steps:

[0035] (1) Use ABAP to regularly collect and summarize the entire business process, drawings, inventory, and contract resource information data of the ERP system, and automatically collect the data to the data center in an incremental or full manner through Oracle tasks;

[0036] (2) After the data center receives the data, it cleans the data, unifies the data format, deletes duplicate values, processes missing data, and checks the accuracy of the data.

[0037] (3) By setting the early warning threshold for the key nodes of power material supply, corresponding processing is carried out through different business logics. For the business processing nodes close to the threshold, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com