Grain drying control system and drying control method thereof

A control system and drying control technology, applied in the sequence/logic controller program control, electrical program control and other directions, can solve the problems of low degree of automation, high cost, manual operation and control equipment operation error, etc. Low equipment consumption, complete functions, and the effect of reducing the phenomenon of dust and the content of toxic and harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] The control system for grain drying in this embodiment comprises: a tower body, an early stage environmental protection treatment module for primary quality management of coal sources and grain sources, an energy delivery module for controlling valves to transport heat sources and wind sources, and a The heat exchange and air distribution module for controlling temperature and air volume exchange, the temperature control boiler module for controlling the boiler to generate a suitable temperature, the coal feeding system module for controlling the automatic coal feeding device for coal feeding, and the controlling gas-liquid purification device for tailing The purification treatment module for waste gas and waste purification treatment at the end, the monitoring module for controlling feedback signals and monitoring, the digital acquisition module for real-time online collection of production status, the metering module for grain output statistics, and the drying technical...

specific Embodiment approach 2

[0024] Different from Embodiment 1, in the grain drying control system of this embodiment, the digital acquisition module includes temperature and moisture sensors

specific Embodiment approach 3

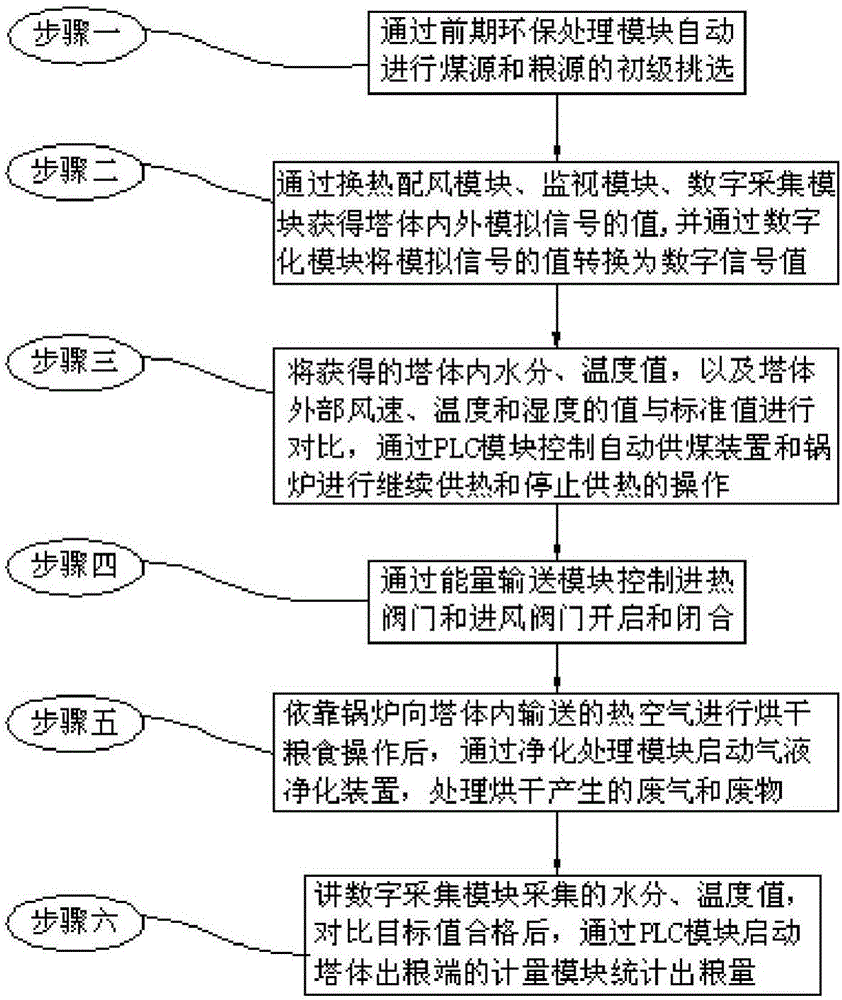

[0025] The grain drying control method of this embodiment,

[0026] Step 1. Through the preliminary environmental protection treatment module, the primary screening of large sand and gravel in the coal source, the preliminary desulfurization, denitrification and dust treatment are automatically carried out, and the primary selection of sundries in the grain source is actively carried out;

[0027] Step 2. Perceive the state of the hot air obtained in the tower body through the heat exchange and air distribution module, monitor the value of the analog signal of wind speed, temperature and humidity outside the tower body through the monitoring module, and collect the moisture and temperature in the tower body online in real time through the digital acquisition module The value of the analog signal, and convert the value of the collected analog signal into a digital signal value through the digitization module;

[0028] Step 3. Compare the obtained moisture and temperature values...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com