Power transmission apparatus

a technology of transmission apparatus and seal, which is applied in the direction of machine/engine, gearing details, drip or splash lubrication, etc., can solve the problem of insufficient lubricant reaching, and achieve the effect of smooth lubrication of seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

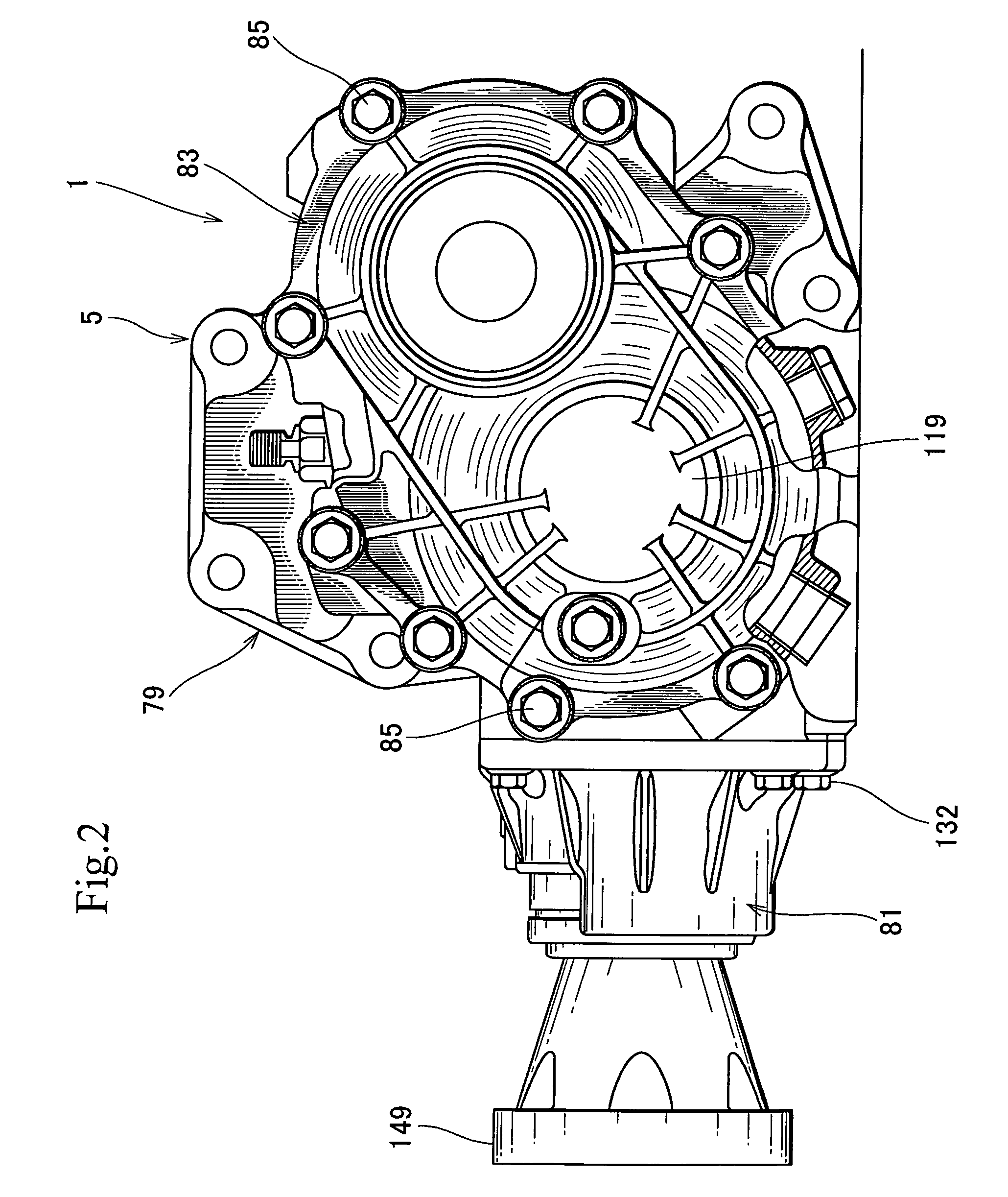

first embodiment

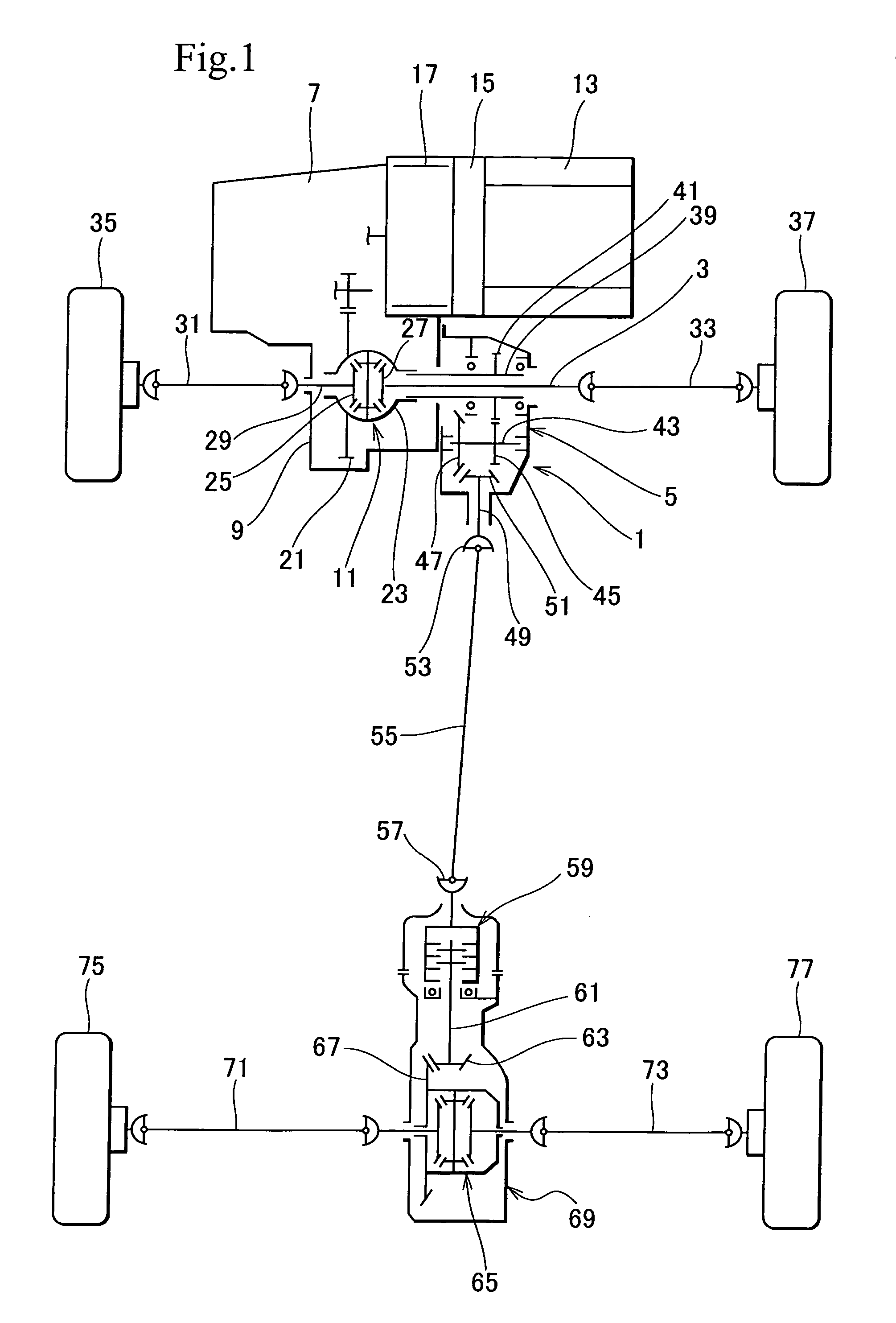

[0026]In the vehicle of FIG. 1, there is arranged a power transmission apparatus 1 according to the present invention. The power transmission apparatus 1 passes therethrough an intermediate axle 3 for front wheels and arranged around the intermediate axle 3. A case 5 of the power transmission apparatus 1 is a transfer case and is attached to a bell housing 9 of a stationary transmission 7.

[0027]The bell housing 9 incorporates a front differential 11. The front differential 11 receives torque from an engine 13 through a main clutch 15, an electric motor 17, and the transmission 7. The torque is transferred through a ring gear 21 to a differential case 23.

[0028]The front differential 11 has left and right side gears 25 and 27 serving as output parts connected to intermediate axles 29 and 3. The intermediate axels 29 and 3 are connected to front-wheel axels 31 and 33, thereby connecting the front differential 11 to the front-wheel axels 31 and 33. The front-wheel axels 31 and 33 are co...

second embodiment

[0085]In FIGS. 6 and 7, the power transmission apparatus 1A of the second embodiment has a lubricant guide 157A. The lubricant guide 157A has a channel 159A that is present only in a second chamber 89. An end of the channel 159A is open above a helical spur gear 45.

[0086]In FIGS. 8, 9, and 10, a case cover 83A according to the second embodiment has a passage hole 175A, a groove 177A, and passage ribs 179 and 181. The ribs 179 and 181 form a part of the lubricant guide 157A and are oriented toward a bearing support 123A. Under the open end of the channel 159A, an inclined rib 183 is formed on the case cover 83A. A lower end of the rib 183 is connected to the passage rib 181.

[0087]The bearing support 123A has a passage groove 184 to guide lubricant from the ribs 179 and 181 toward the back side of a tapered roller bearing 127.

[0088]According to the second embodiment, a ring gear 47 takes up lubricant from a lubricant surface F as indicated with arrows shown in FIGS. 6 and 7. The lubri...

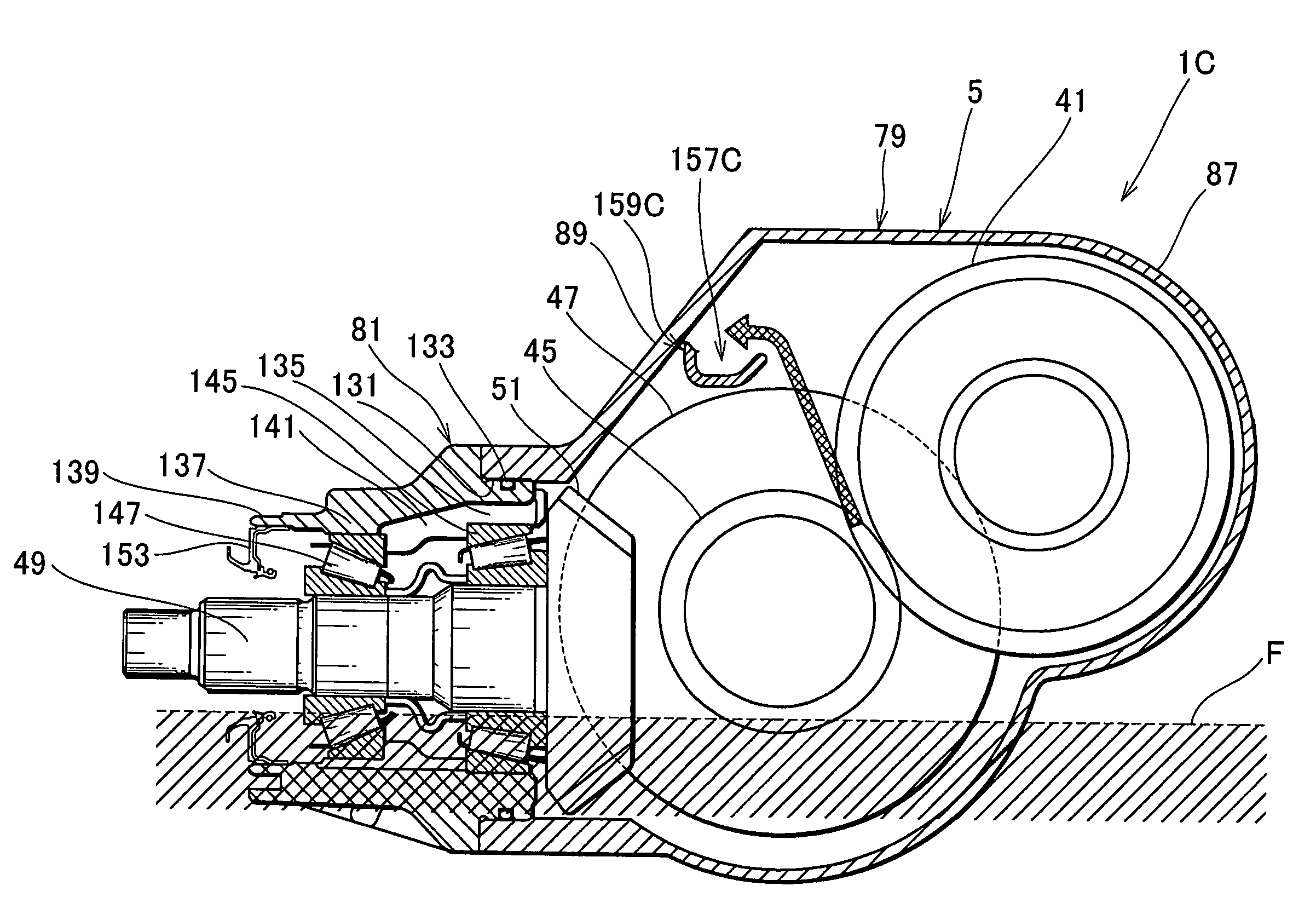

third embodiment

[0093]In FIGS. 11 and 12, the power transmission apparatus 1B has a lubricant guide 157B. The lubricant guide 157B has a channel 159B that is present only in a second chamber 89. The channel 159B is inclined so as to gradually deepen toward the ring gear 47 of the intermediate shaft 43 as the second shaft. An end of the channel 159B is open above a ring gear 47. The channel 159B of the lubricant guide 157B is inclined to receive lubricant splashed by a helical spur gear (parallel meshing gear) 45 and pass the received lubricant toward the ring gear (orthogonal meshing gear) 47.

[0094]According to the third embodiment, the helical spur gear 45 scoops lubricant as indicated with arrows shown in FIGS. 11 and 12. The lubricant is received by the channel 159B and is passed through the open end of the channel 159B above the ring gear 47 toward a tapered roller bearing 125 and an oil seal 103.

[0095]To guide lubricant, the third embodiment may have, like the second embodiment, ribs on an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com