Packaging bag filling type automatic grease gun

A packaging bag and grease gun technology, applied in engine components, manual lubricant supply, engine lubrication, etc., can solve the problems of cumbersome operation, waste, grease pollution, etc., to improve work efficiency, simple structure, and ensure cleanliness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

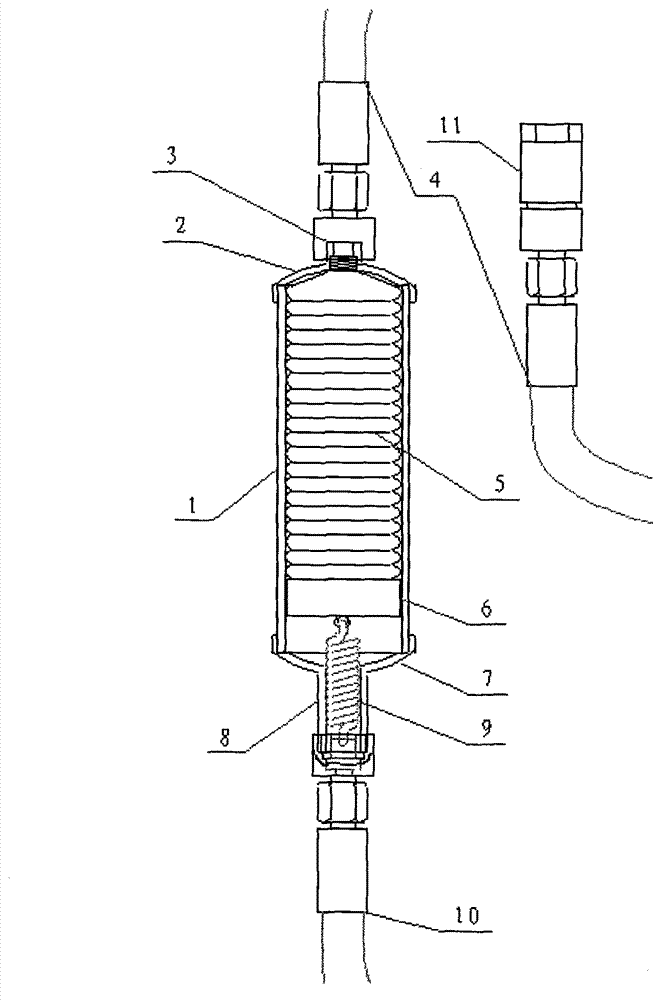

[0009] In Fig. 1, the packaging bag (5) filled with grease is a soft plastic corrugated tube bottle, with the mouth up and the bottom down into the grease storage tube (1), and the upper end of the grease storage tube (1) is threaded and The top cover (2) is connected, and the center of the top cover (2) has a grease outlet (3) connected to the grease nipple at the position to be lubricated through the grease conduit (4). The lower end of the grease storage tube (1) is connected to the bottom cover (7) by threads, and there is a piston (6) between the bottom cover (7) and the grease packaging bag (5), and the center of the bottom cover (7) is a spring sleeve (8), an extension spring (9) is worn inside, and one end of extension spring (9) is connected with piston (6), and the other end is fixed on extension spring casing (8) top, and the top of spring casing (8) Then a high-pressure flexible pipe (10), the high-pressure flexible pipe (10) is connected with the outlet of a set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com