Lever-type automatic oiling device

An automatic refueling, lever-type technology, applied in the direction of engine components, engine lubrication, lubricating oil input, etc., can solve problems such as inconvenience in processing, affecting processing, machine tool alarms, etc., to reduce workload, reduce the impact of friction, Guarantee the effect of normal processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

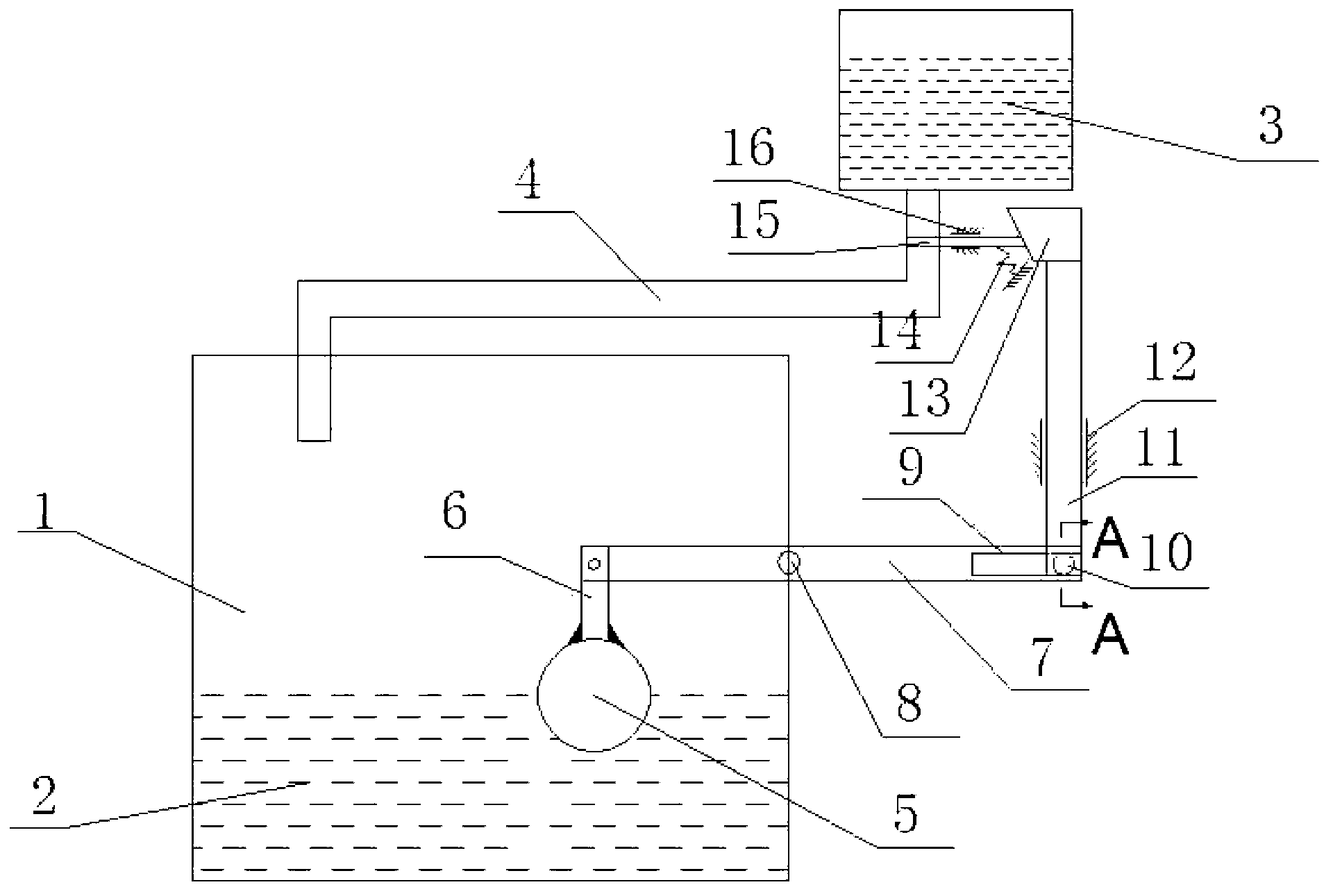

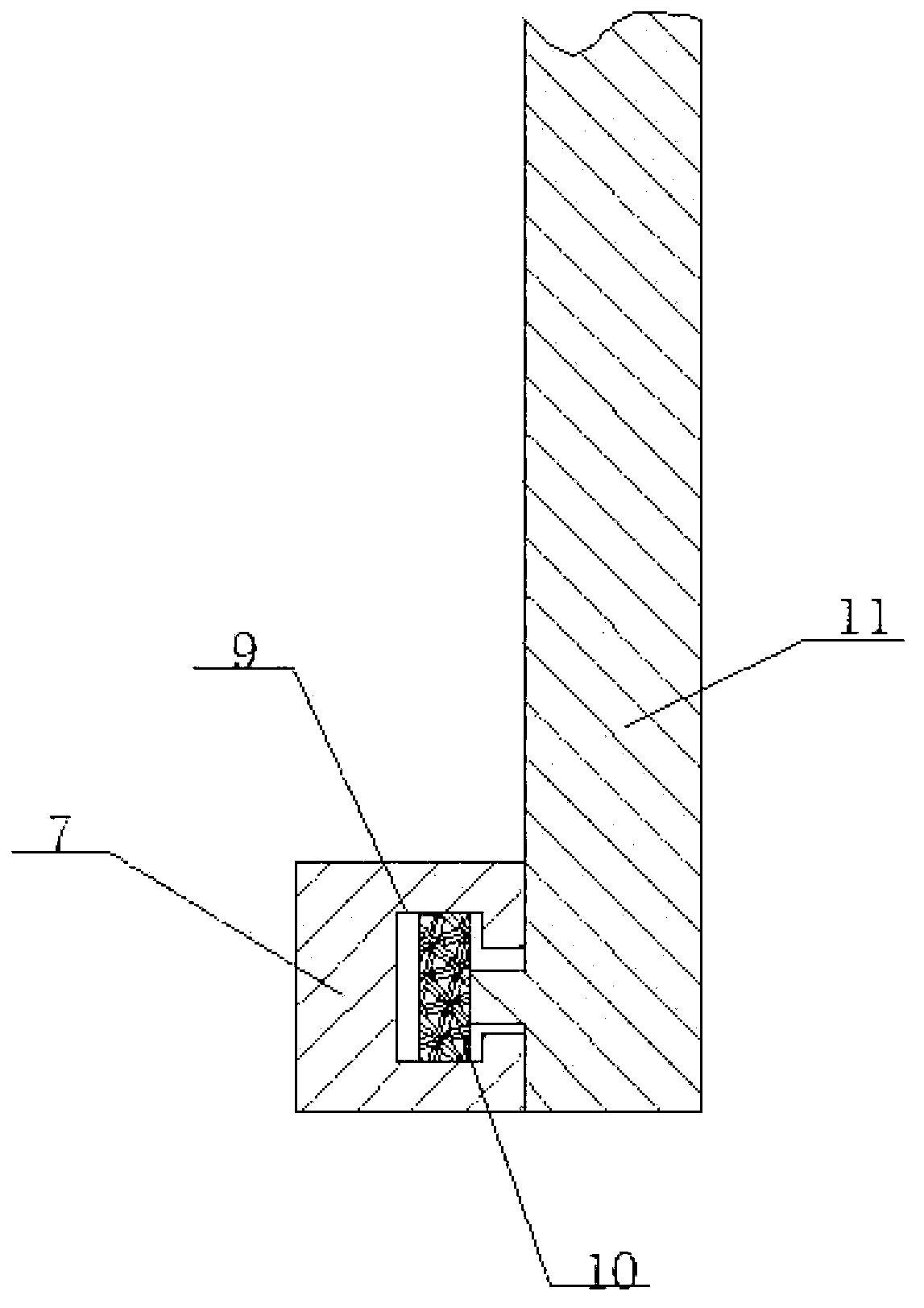

[0012] Figure 1 to Figure 2 Shown is a lever-type automatic refueling device. The working oil tank 1 is used to store the lubricating oil 2 required for the operation of the machine tool. The external oil storage tank 3 is connected to the working oil tank 1 through the oil delivery pipe 4. The floating ball 5 is suspended in the working oil tank 1. On the lubricating oil 2, one end of the floating rod 6 is fixed with the floating ball 5, and the other end is hinged with the lever 7, the lever 7 is hinged with the working oil tank 1 through the hinge 8, the other end of the lever 7 is provided with a chute 9, and one end of the push rod 11 is provided with a roller 10. The roller 10 cooperates with the chute 9, the push rod 11 is guided through the No. 1 guide groove 12, the other end of the push rod 11 is fixed with a wedge block 13, the control rod 15 is guided through the No. 2 guide groove 16, and one end of the control rod 15 is used To control the on-off of the oil deli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com