An automatic painting equipment for outdoor pipeline surface

A pipeline and outdoor technology, applied in the device and coating of the surface coating liquid, can solve the problems of reducing the risk, high risk of manual painting, cumbersome engineering process, etc., to avoid manual push and high degree of automation , Improve the effect of painting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

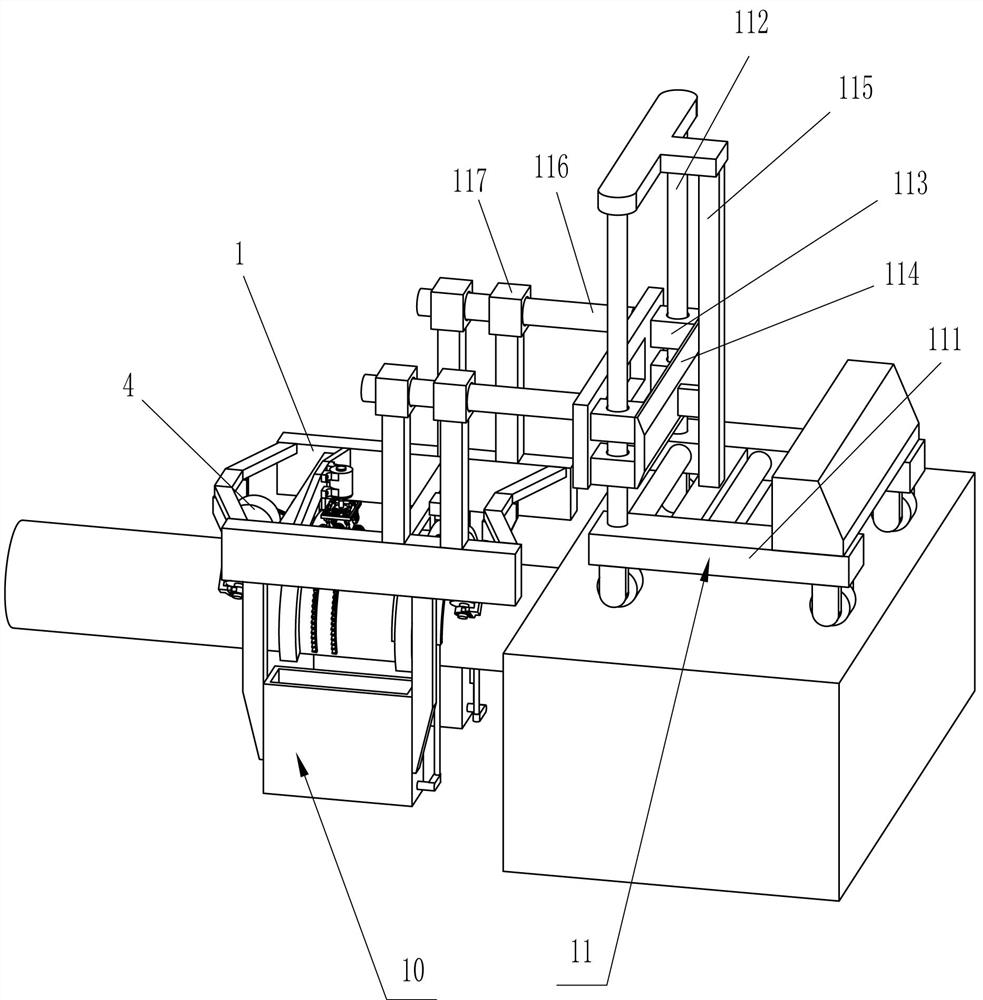

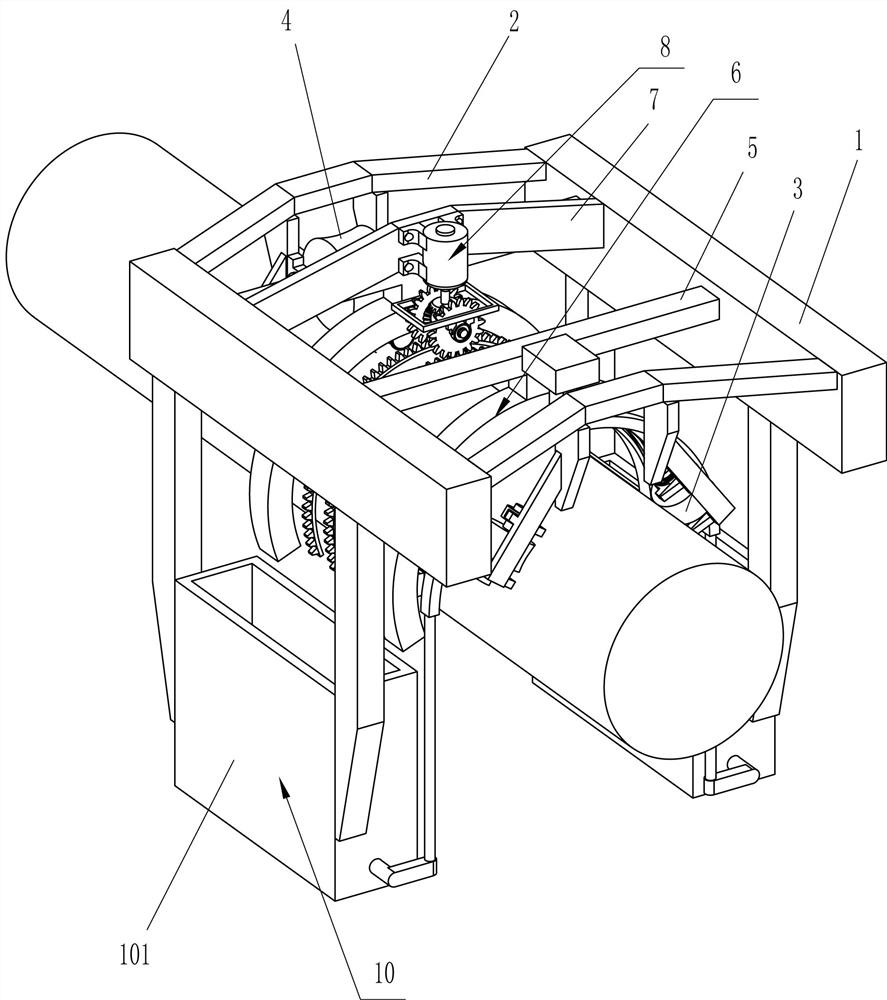

[0029] A kind of outdoor pipe surface automatic painting equipment, such as Figure 1-4 As shown, it includes a mounting frame 1, a first connecting frame 2, a guide wheel 3, a driving wheel 4, a second connecting frame 5, a painting device 6, a third connecting frame 7, a driving device 8, a transmission device 9 and a painting device 10, specifically:

[0030] The number of mounting frames 1 is two groups, and the first connecting frame 2 is connected between the left and right sides of the mounting frame 1, and the first connecting frame 2 of each group is connected with guide wheels 3 in rotation on both sides, and the first connecting frame 2 on the left side The middle part is rotatably connected with the driving wheel 4, two second connecting frames 5 are connected between the mounting frames 1, a painting device 6 is arranged between the second connecting frames 5, and a third connecting frame is connected in the middle between the mounting frames 1 7. The third conne...

Embodiment 2

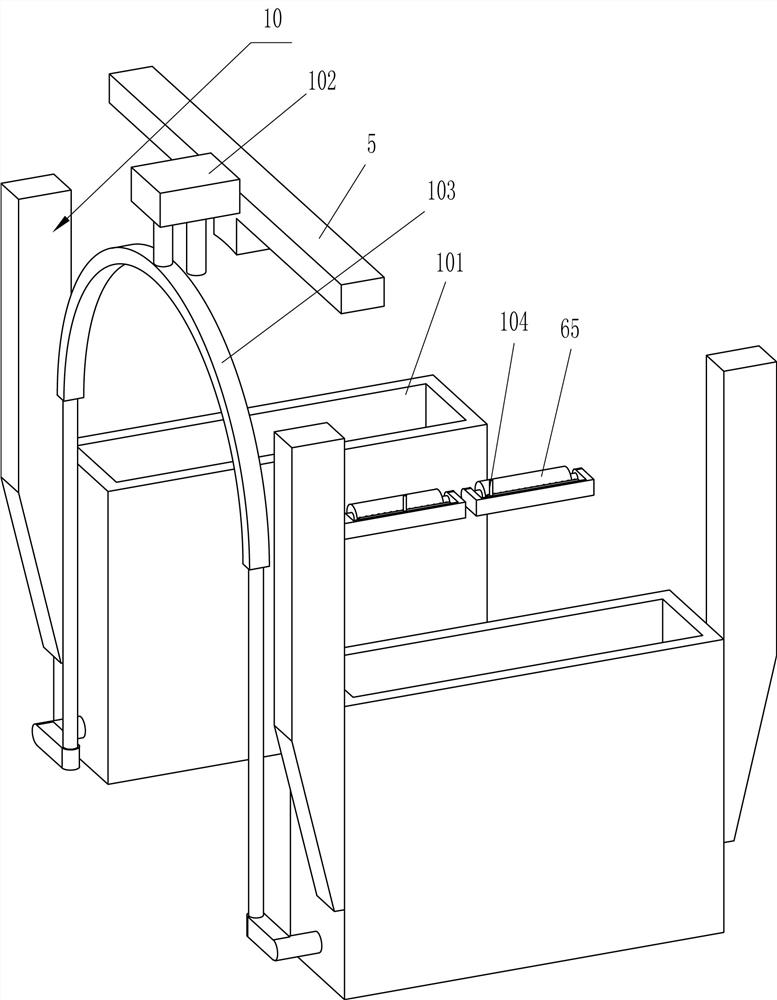

[0033] On the basis of Example 1, such as Figure 4-10 As shown, the painting device 6 includes an arc-shaped slide rail 61, a slide block 62, a long arc-shaped plate 63, a short arc-shaped plate 64, a paint brushing cylinder 65 and a first rack 66, specifically:

[0034] The lower side of the second connecting frame 5 is connected with an arc-shaped slide rail 61, and the inside of the arc-shaped slide rail 61 is slidably connected with a slider 62. The slide block 62 in the left arc-shaped slide rail 61 is positioned behind it, and the left side Slide block 62 is connected with transmission device 9, and slide block 62 in the right side arc slide rail 61 is positioned at its front, and right side slide block 62 is connected with long arc plate 63, and left side slide block 62 is connected with short arc plate. Plate 64, the long arc plate 63 rear side end and the short arc plate 64 end are located on the same straight line, and the long arc plate 63 end and the left side sli...

Embodiment 3

[0046] On the basis of Example 2, such as figure 1 As shown, transfer device 11 is also included, and transfer device 11 includes vehicle frame 111, first guide rail 112, first guide sleeve 113, moving frame 114, electric slide rail 115, second guide rail 116 and second guide sleeve 117, Specifically:

[0047] Mounting frame 1 is provided with transfer device 11, and transfer device 11 is used for transferring this equipment conveniently on shore base, and shore base is provided with vehicle frame 111, and two groups of first guide rails 112 are connected on the upper side of vehicle frame 111, and first guide rail 112 The first guide sleeve 113 is slidingly connected on the top, and the mobile frame 114 is connected between the first guide sleeves 113. The upper middle part of the vehicle frame 111 is connected with an electric slide rail 115, and the moving part of the electric slide rail 115 is connected with the mobile frame 114. A second guide rail 116 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com