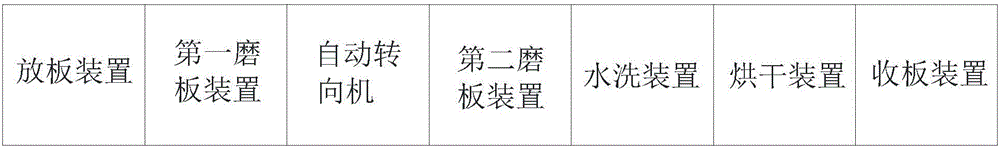

Novel method for removing porthole flashing of PCB

A new type of PCB board technology, applied in the field of new-type PCB board hole removal, can solve problems such as increased labor intensity of employees, poor hole removal effect, uneven copper surface polishing, etc., to reduce manual handling actions, Good effect, guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for removing orifice drape on a novel PCB board is characterized in that it comprises the steps:

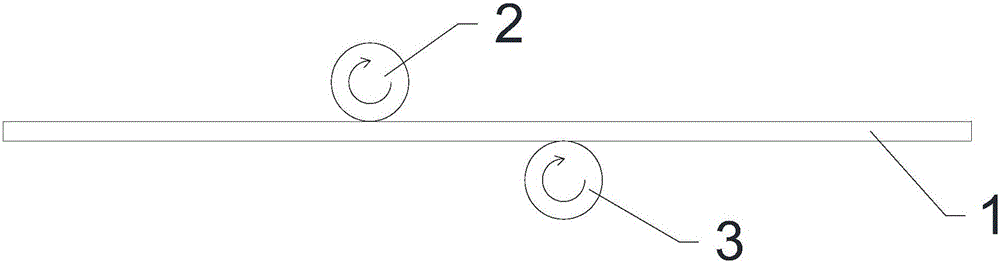

[0026] Grinding for the first time: put the drilled PCB 1 into the first grinding device for the first grinding. The first grinding device includes a pair of upper and lower grinding wheels, and the grinding wheels are provided with grinding brushes;

[0027] Horizontal 90° steering: through the automatic steering machine arranged between the first grinding device and the second grinding device, the PCB board 1 after the first grinding is rotated horizontally by 90°;

[0028] The second grinding plate: Put the PCB board 1 turned horizontally by 90° into the second grinding plate device for the second grinding plate. The second grinding plate device includes a pair of upper and lower grinding wheels, and the grinding wheel is equipped with a grinding wheel. brush.

Embodiment 2

[0030] A method for removing orifice drape on a novel PCB board is characterized in that it comprises the steps:

[0031] Board placement: use the automatic board placement device to put the drilled PCB board 1 into the first grinding board device in the next step;

[0032] Grinding for the first time: the first grinding device is used to grind the drilled PCB board 1 placed in the automatic plate placing device for the first time. The first grinding device includes two pairs of upper and lower grinding wheels. There are grinding brushes, and the two pairs of grinding wheels turn in the same direction;

[0033] Horizontal 90° steering: through the automatic steering machine arranged between the first grinding device and the second grinding device, the PCB board 1 after the first grinding is rotated horizontally by 90°;

[0034] The second grinding plate: Put the PCB board 1 turned horizontally by 90° into the second grinding plate device for the second grinding plate. The sec...

Embodiment 3

[0040] A method for removing orifice drape on a novel PCB board is characterized in that it comprises the steps:

[0041] Board placement: use the automatic board placement device to put the drilled PCB board 1 into the first grinding board device in the next step;

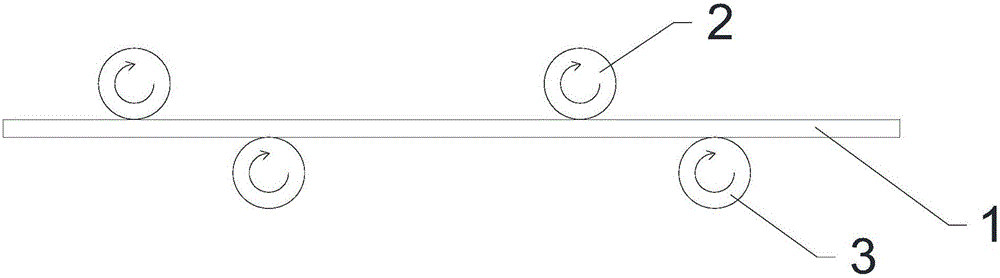

[0042] Grinding for the first time: the first grinding device is used to grind the drilled PCB board 1 placed in the automatic plate placing device for the first time. The first grinding device includes two pairs of upper and lower grinding wheels. There are grinding brushes, the upper grinding wheel 2 of the first pair of grinding wheels is opposite to the upper grinding wheel 2 of the second pair of grinding wheels, and the lower grinding wheel 3 of the first pair of grinding wheels is opposite to the lower grinding wheel 3 of the second pair of grinding wheels;

[0043] Horizontal 90° steering: through the automatic steering machine arranged between the first grinding device and the second grinding device, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com