Wood board surface paint brushing device for furniture production

A technology of wood board and painting, which is applied to devices and coatings that apply liquid to the surface, which can solve the problems of time-consuming and labor-intensive, reducing the utilization rate of paint, and the processing effect is not very good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

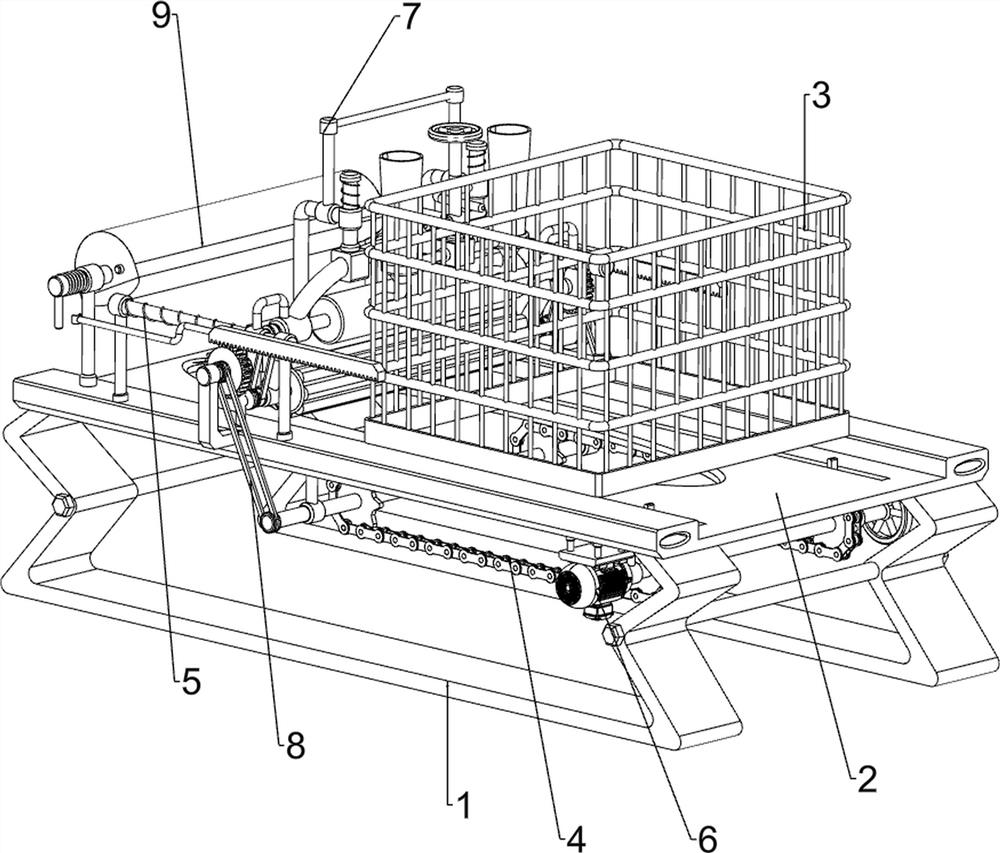

[0062] A device for painting the surface of wooden boards used in furniture production, such as Figure 1-3 As shown, it includes a support foot 1, a first installation plate 2, a placement frame 3, a pushing mechanism 4 and a driving mechanism 5, a first installation plate 2 is provided between the support feet 1, and a placement frame is provided on the right side of the first installation plate 2 3. A pushing mechanism 4 is provided at the bottom of the first mounting plate 2 , and a driving mechanism 5 is provided at the left side of the middle of the first mounting plate 2 .

[0063] When people need to paint the surface of the furniture plank, this device can be used. First, the plank is put into the placement frame 3, so that the plank falls on the first mounting plate 2, and then the brush material is poured into the drive mechanism 5 parts, and then People manually rotate the 4 parts of the pushing mechanism so that the 4 parts of the pushing mechanism push the plank ...

Embodiment 2

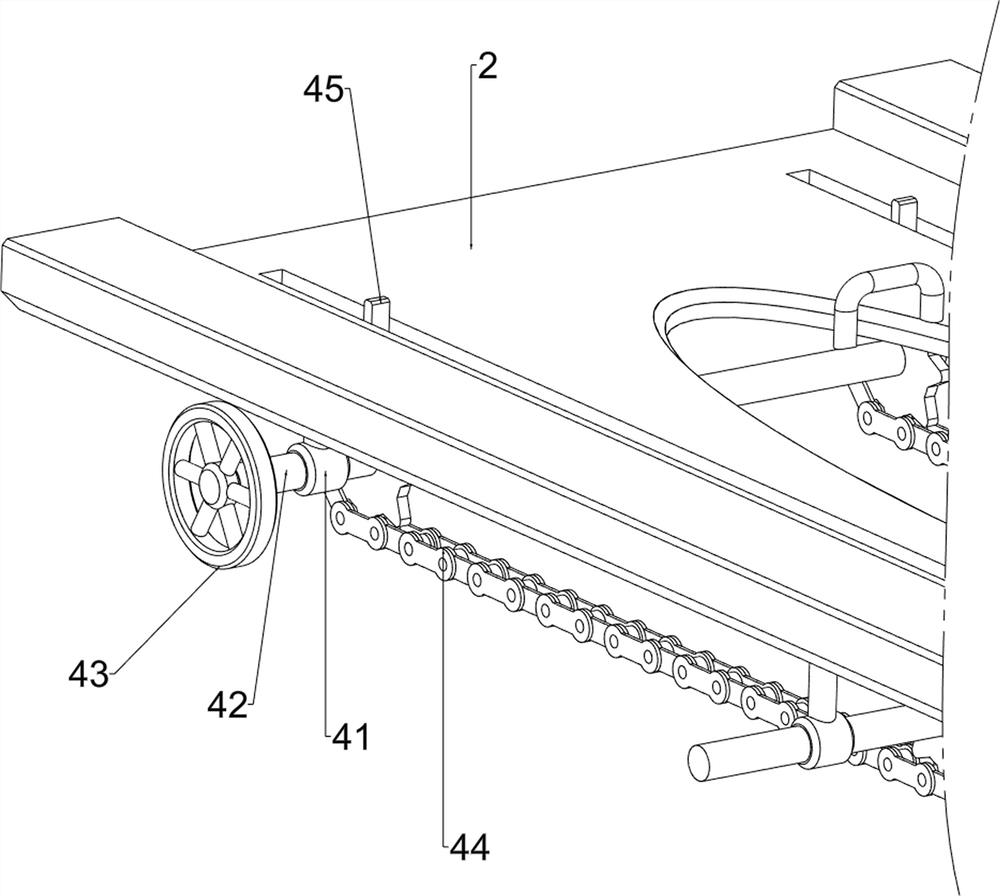

[0069] On the basis of Example 1, such as Figure 4-7 As shown, it also includes a scrubbing mechanism 6. The scrubbing mechanism 6 includes a third bracket 61, a second mounting plate 62 and a motor 63. Four third brackets 61 are arranged on the right front side of the bottom of the first mounting plate 2. The third bracket 61 A second mounting plate 62 is provided between them, and a motor 63 is provided at the bottom of the second mounting plate 62, and the output shaft of the motor 63 is connected to the front side of the first rotating shaft 42 on the right side.

[0070] When the plank falls from the placement frame 3 onto the first mounting plate 2, people start the motor 63, and the output shaft of the motor 63 drives the first rotating shaft 42 to rotate, and people do not need to manually turn the first handle 43 to push the plank to the brush 59 below, after using this equipment, close motor 63 and get final product.

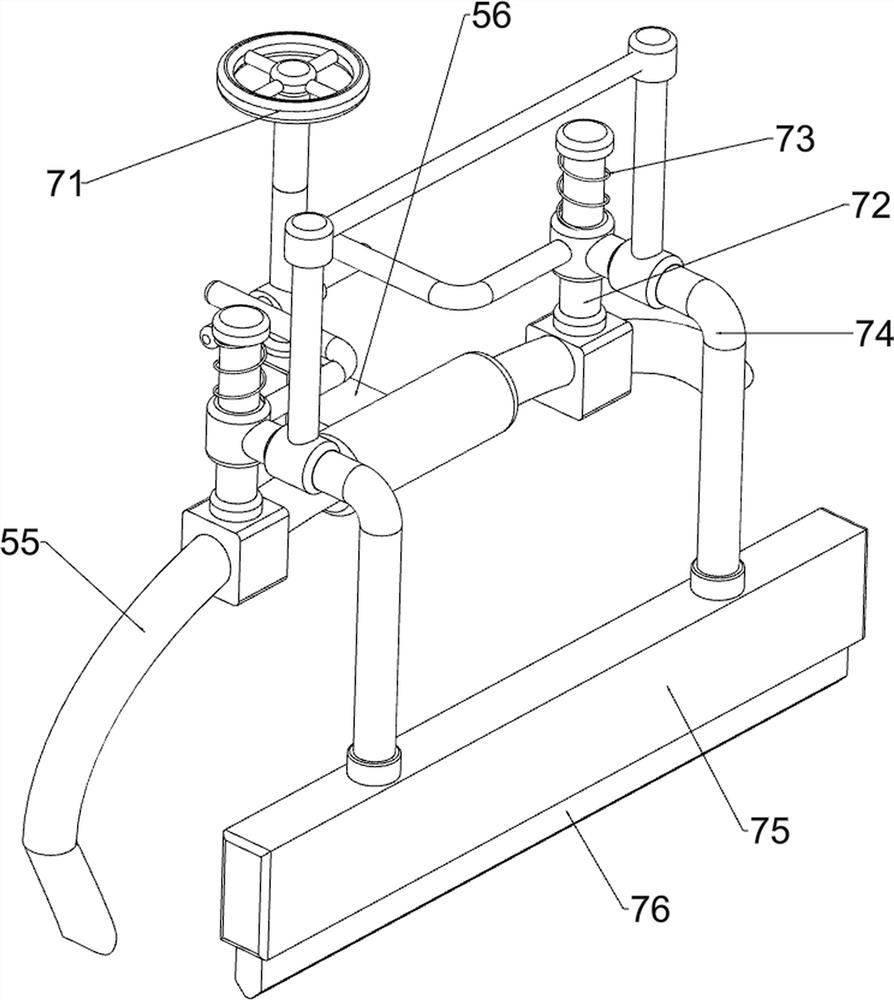

[0071] Also include a scraper mechanism 7, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com