Efficient waste gas recovery device for paper production

A waste gas recovery and high-efficiency technology, which is applied in the directions of transportation and packaging, cleaning methods and utensils, and smoke and dust removal, can solve the problems of reducing waste gas treatment efficiency, failing to ensure health, and increasing labor consumption, so as to improve the filtering effect and improve convenience. Non-toxic, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

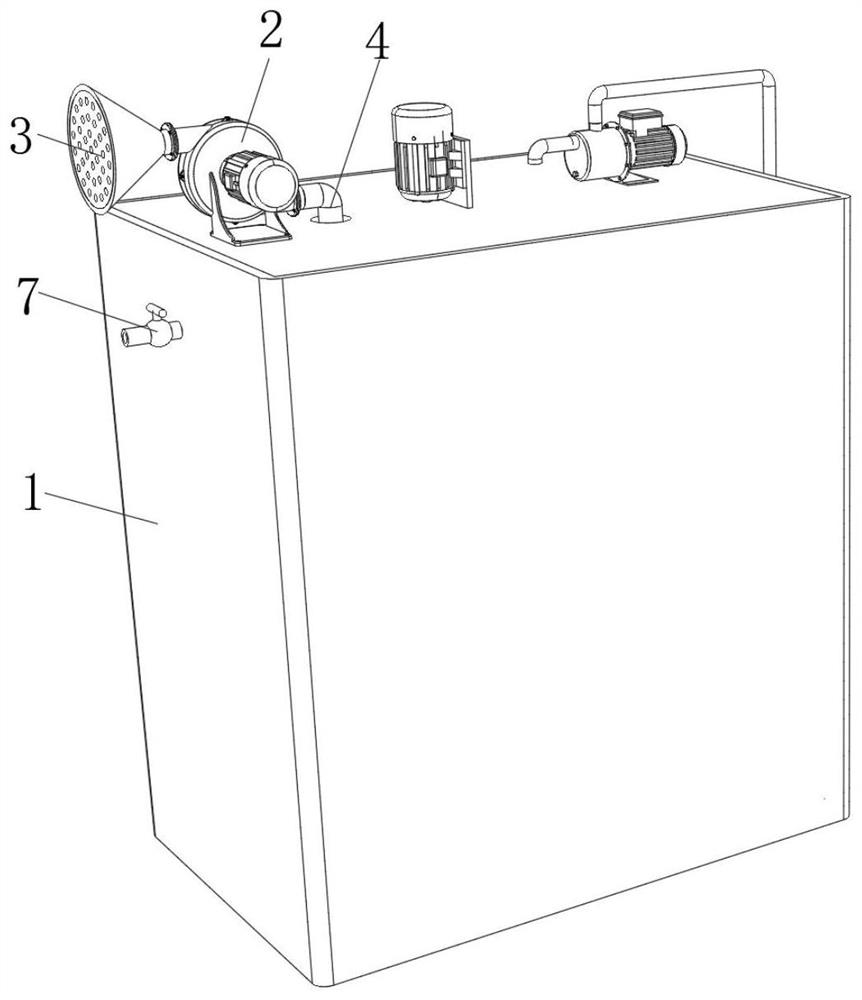

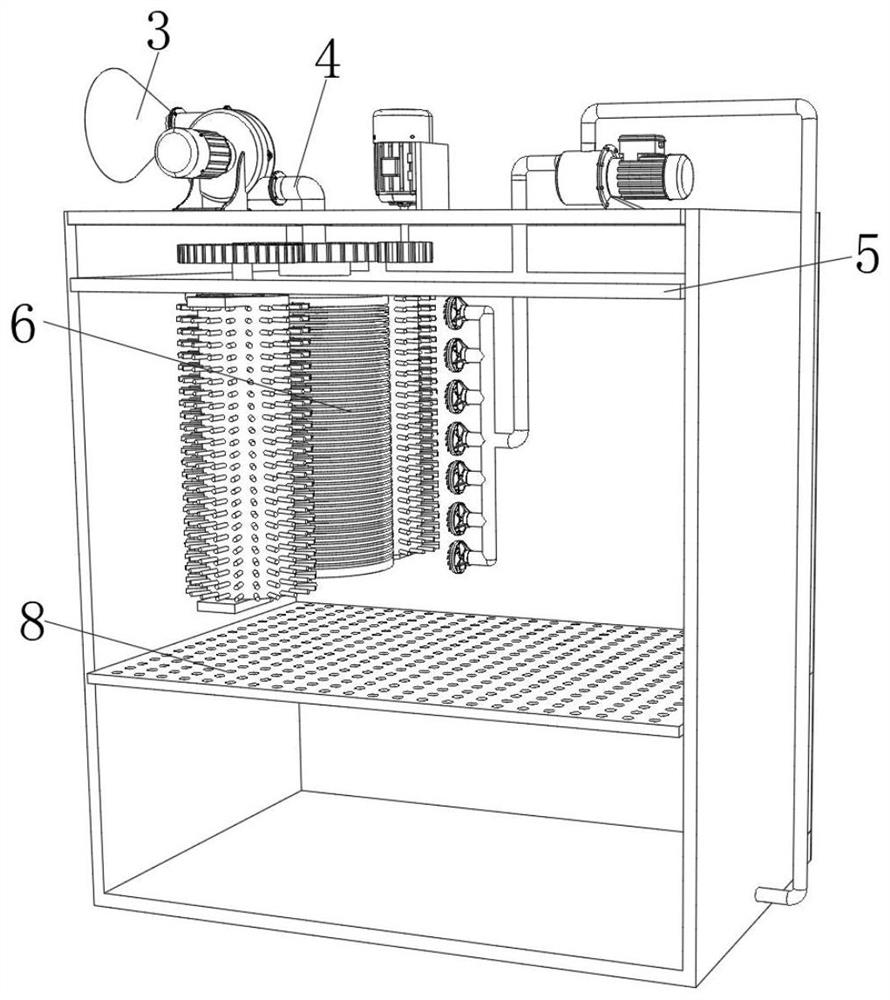

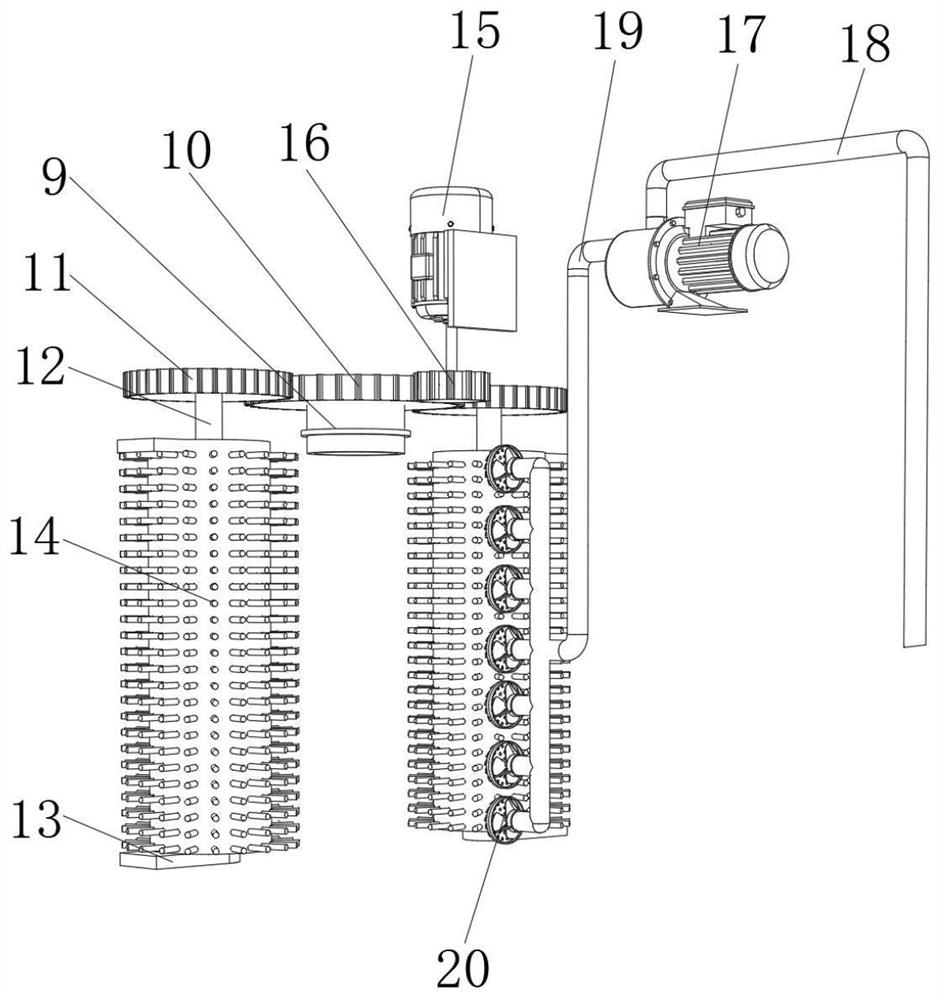

[0025] see Figure 1-3 , the present invention provides a technical solution: a waste gas recovery device for high-efficiency paper production, including a waste gas recovery box 1, a suction fan 2 is fixedly connected to the left side of the upper surface of the waste gas recovery box 1, and the input end of the suction fan 2 is connected to a The air inlet hood 3, the output end of the suction fan 2 is connected to the transmission pipe 4, the inner top of the waste gas recovery box 1 is fixedly connected with a stable support plate 5, the bottom of the transmission pipe 4 is provided with a filter column 6, and the left side of the waste gas recovery box 1 The top of the exhaust valve 7 is connected to the exhaust valve 7, the inner bottom of the waste gas recovery box 1 is fixedly connected with a high-efficiency filter plate 8, and the left side of the upper surface of the stable support plate 5 is provided with a rotating and stabilizing ring 9, and the upper surface of t...

Embodiment 2

[0034] see Figure 1-2 and Figure 4 , the present invention provides a technical solution: a waste gas recovery device for high-efficiency paper production, including a waste gas recovery box 1, a suction fan 2 is fixedly connected to the left side of the upper surface of the waste gas recovery box 1, and the input end of the suction fan 2 is connected to a The air inlet hood 3, the output end of the suction fan 2 is connected to the transmission pipe 4, the inner top of the waste gas recovery box 1 is fixedly connected with a stable support plate 5, the bottom of the transmission pipe 4 is provided with a filter column 6, and the left side of the waste gas recovery box 1 The top of the exhaust gas recovery box 1 is connected with an exhaust valve 7, and the inner bottom of the waste gas recovery box 1 is fixedly connected with a high-efficiency filter plate 8.

[0035] In the present invention, in order to improve the filtering effect, there are many groups of filter throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com