Dust filtering device for shearing of hot-rolled ribbed steel bars and use method of dust filtering device

A technology of dust filtering device and hot-rolled ribbed steel bar, applied in separation method, combined device, dispersed particle filtering, etc., can solve the problems of poor dust treatment effect and inconvenient maintenance, so as to improve operation quality and use efficiency, improve The degree of automation, the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

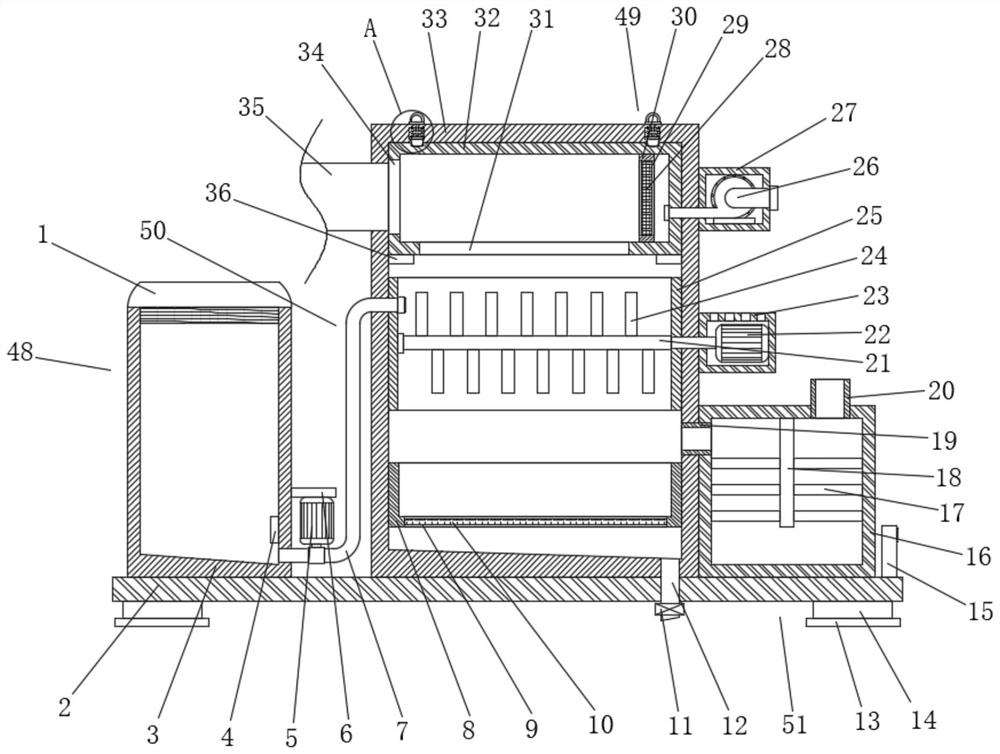

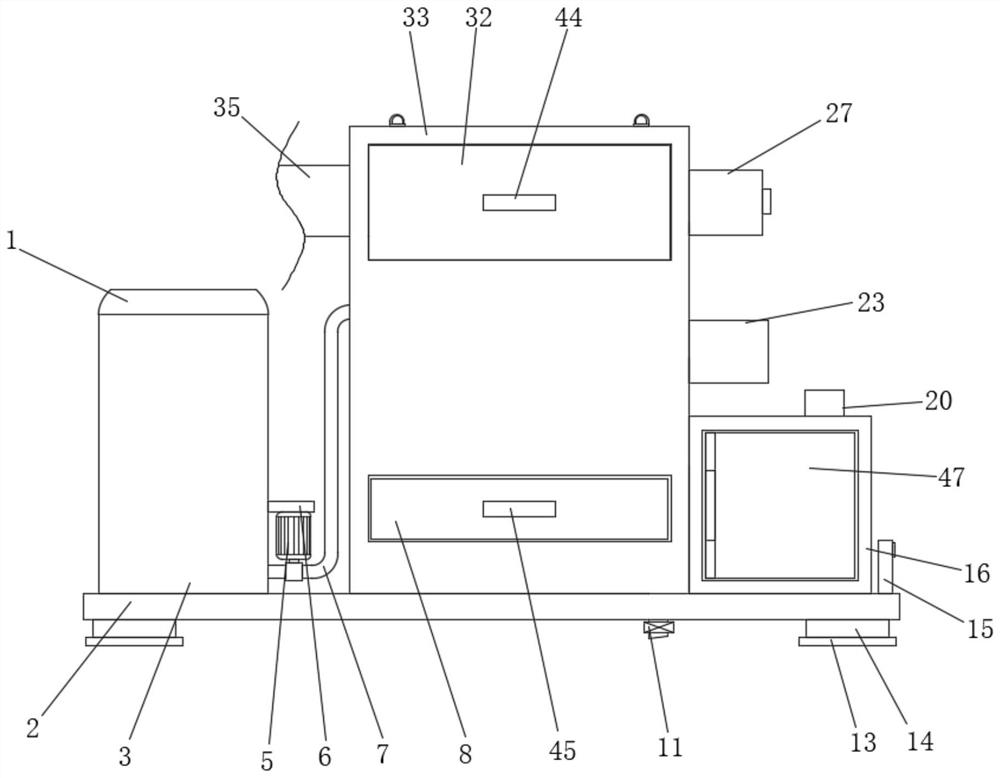

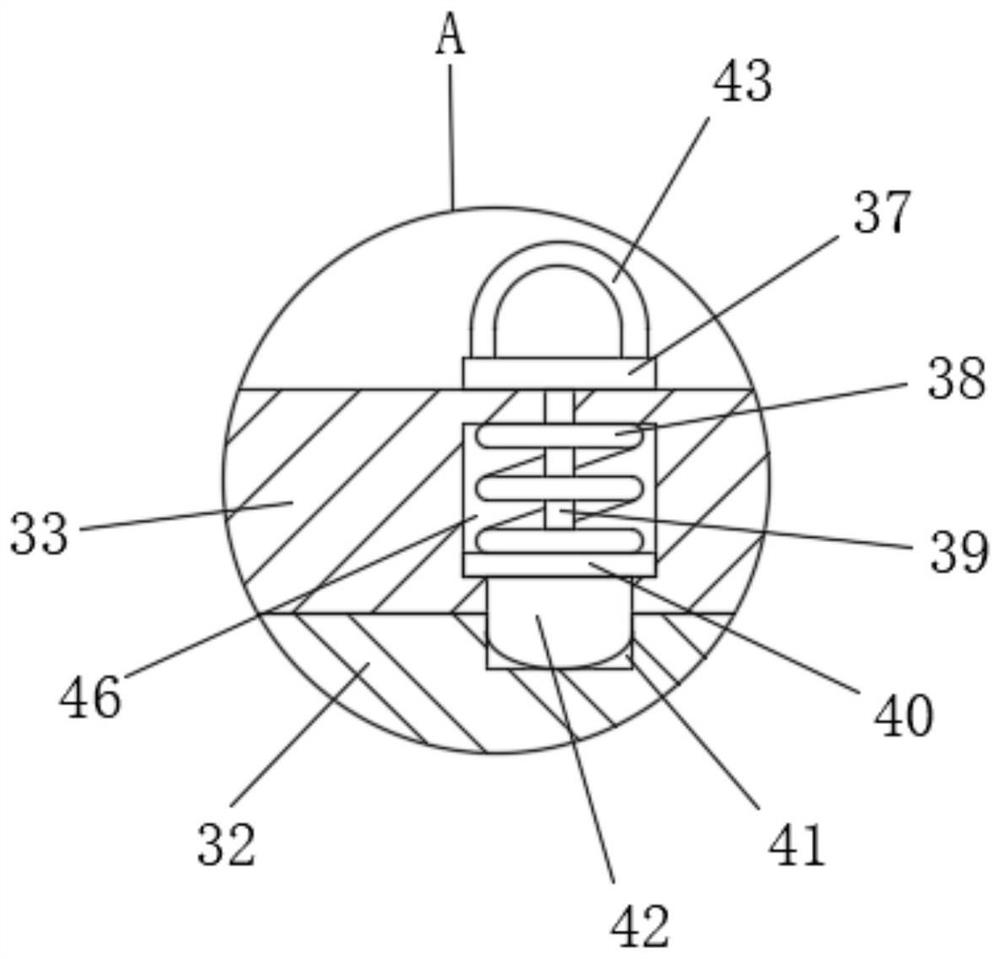

[0026] A dust filter device for shearing hot-rolled ribbed steel bars, comprising a bottom plate 2, the top of the bottom plate 2 is provided with a feed assembly 48, the top of the bottom plate 2 is fixedly installed with an installation box 33, and the inside of the installation box 33 is slidingly connected with a third Mounting box 32, the outside of the 3rd mounting box 32 is provided with the 4th mounting groove 34, and the outside of mounting box 33 is fixedly installed with feed pipe 35, and the bottom of the 3rd mounting box 32 offers the 3rd mounting groove 31, and the 3rd installing The bottom of the box 32 is slidably connected with two first sliders 36, and the outsides of the two first sliders 36 are fixedly connected with the installation box 33. The top of the third installation box 32 is provided with two locking assemblies 49. The third installation The second installation plate 30 is fixedly installed between the inwall of box 32, and the outside of the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com