Leather swabbing device

A technology for brushing pulp and leather, applied in the field of leather processing equipment, can solve the problems of time-consuming and laborious work efficiency, reducing leather quality, easily destroying pulp layer, etc., and achieving the effects of low work intensity, uniform brushing and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

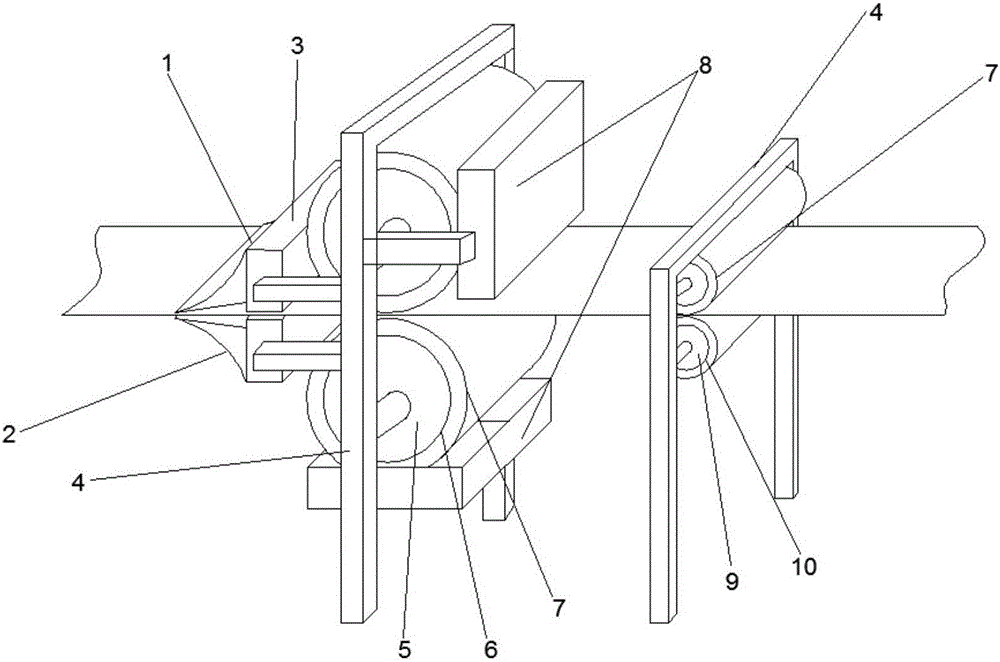

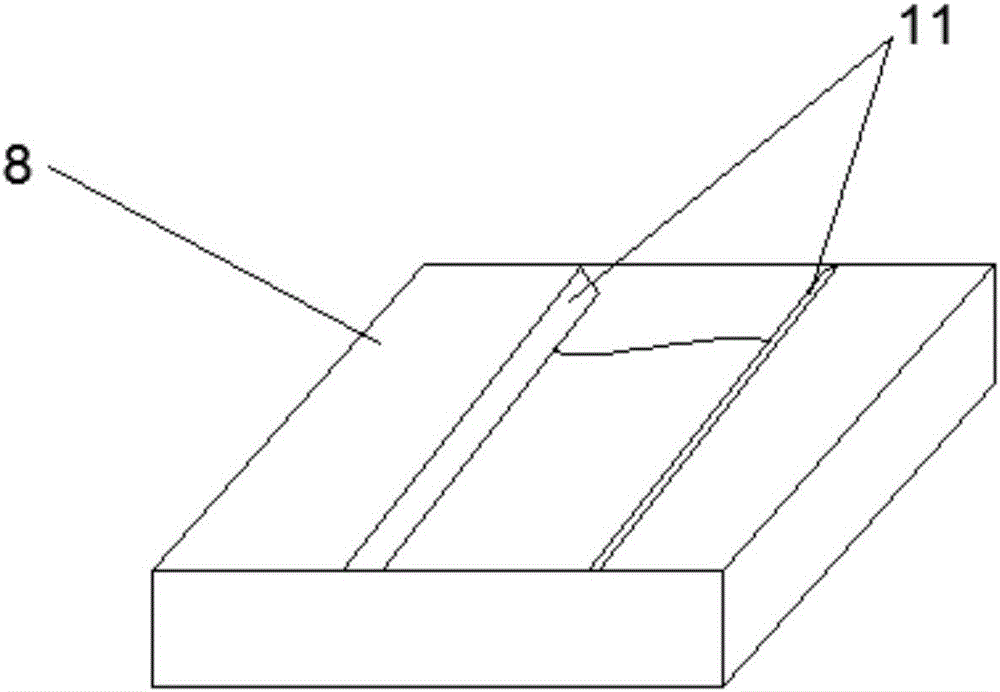

[0013] Referring to the accompanying drawings, in order to make the present invention achieve the required technical effect, the present invention adopts the following embodiments: a leather brushing device, including a cleaning device, a brushing device and a secondary processing device, and the cleaning device includes two symmetrical and The same cleaning block, the cleaning block includes a miscellaneous block and a water-absorbing block, the cleaning block is fixed on the water-absorbing block, the water-absorbing block is connected to a bracket, and a brushing device is installed on the bracket, and the brushing device It includes two symmetrical and identical brushing rollers, on which a sponge cover is provided, on which a slurry box is arranged, and the secondary processing device is two symmetrical and identical brushes fixed on the bracket. The laminating roller is provided with a sponge cover.

[0014] Preferably, the cleaning block, the brushing roller and the lam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com