Exoskeleton mechanism based on parallelogram connection-rod and wire rope

A parallelogram, link mechanism technology, applied in manipulators, program-controlled manipulators, motion accessories, etc., can solve problems such as bloated mechanisms, complex control strategies, and the drive device and exoskeleton mechanism are not integrated. The effect of high integration and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

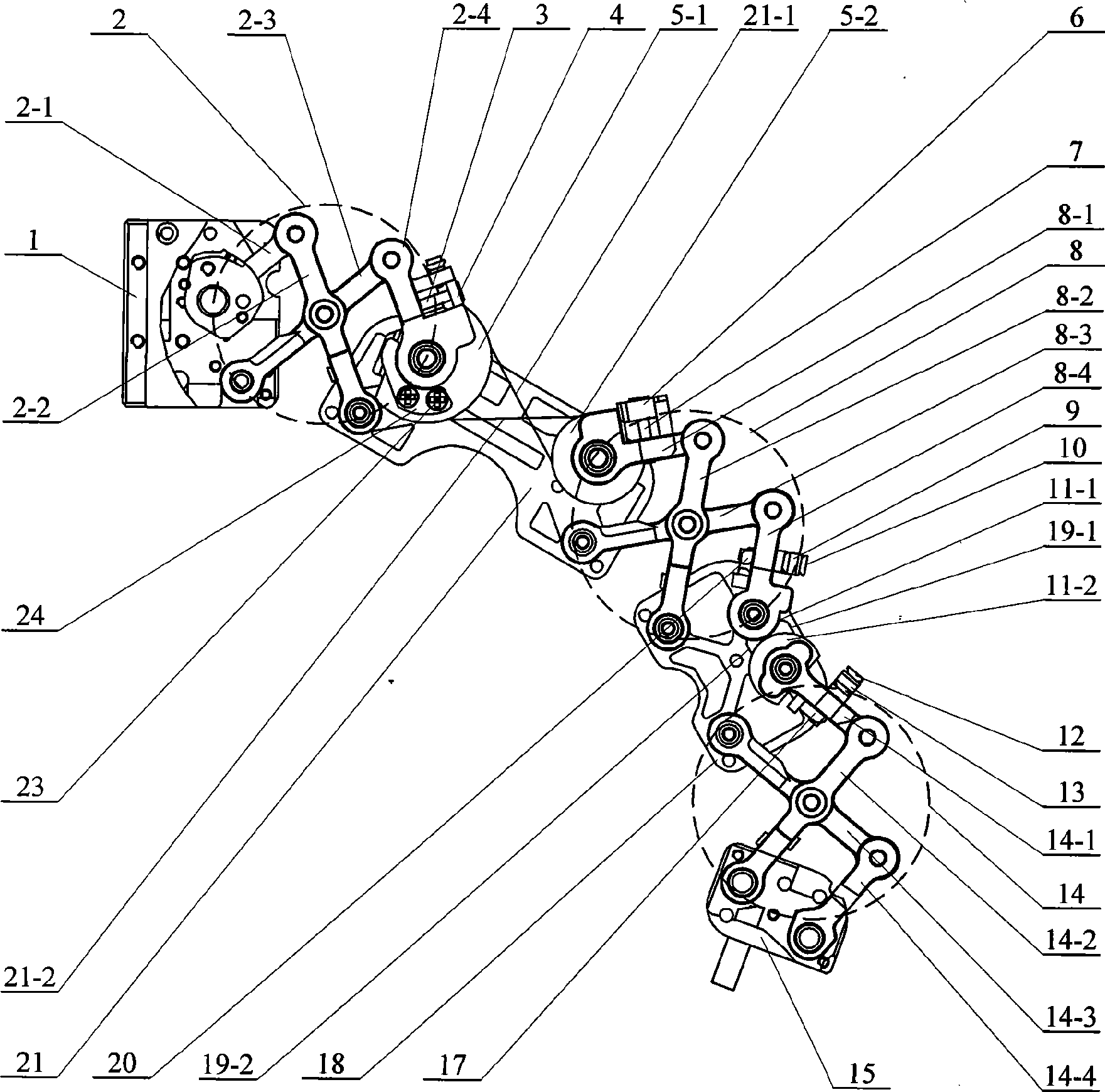

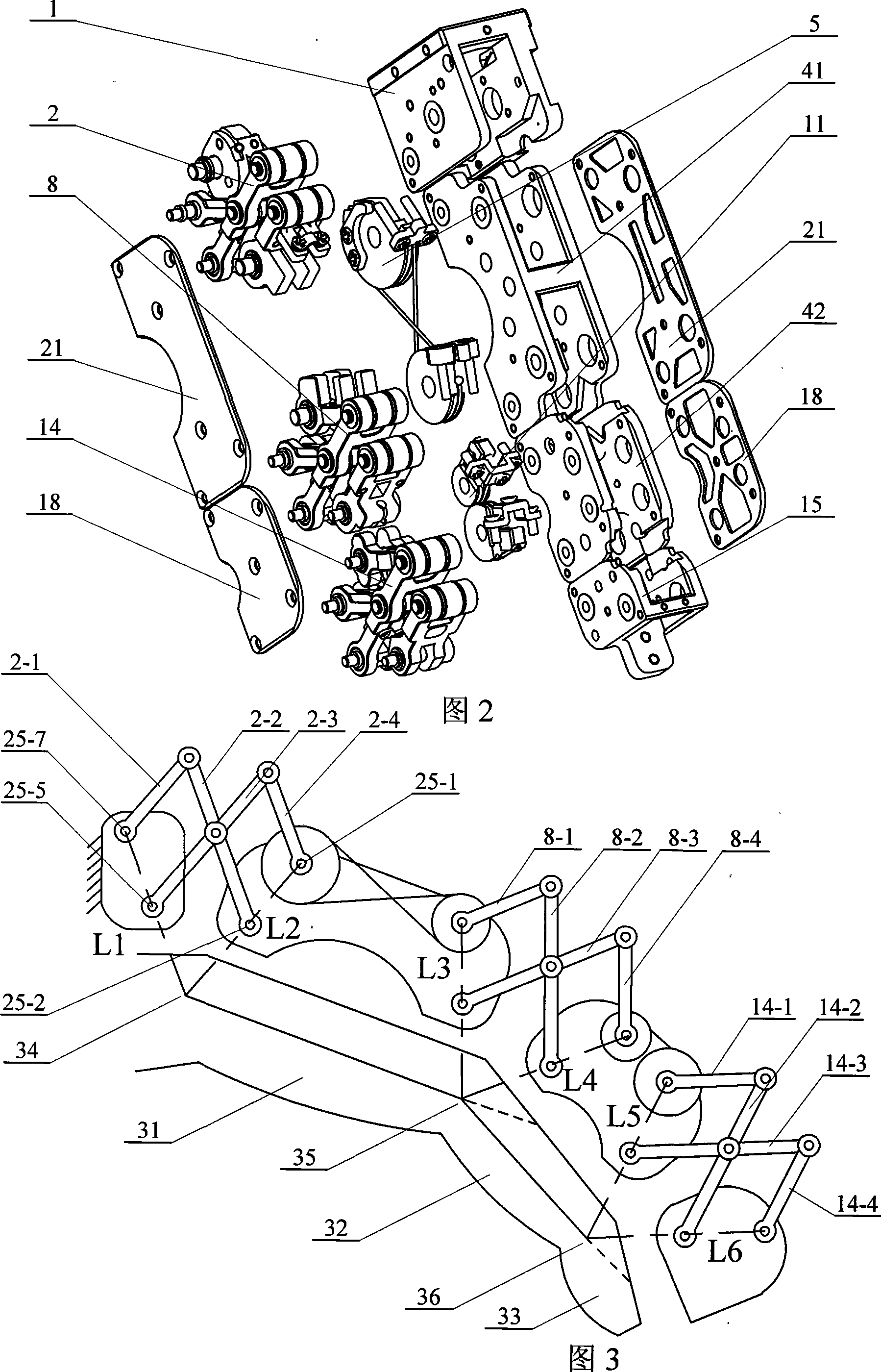

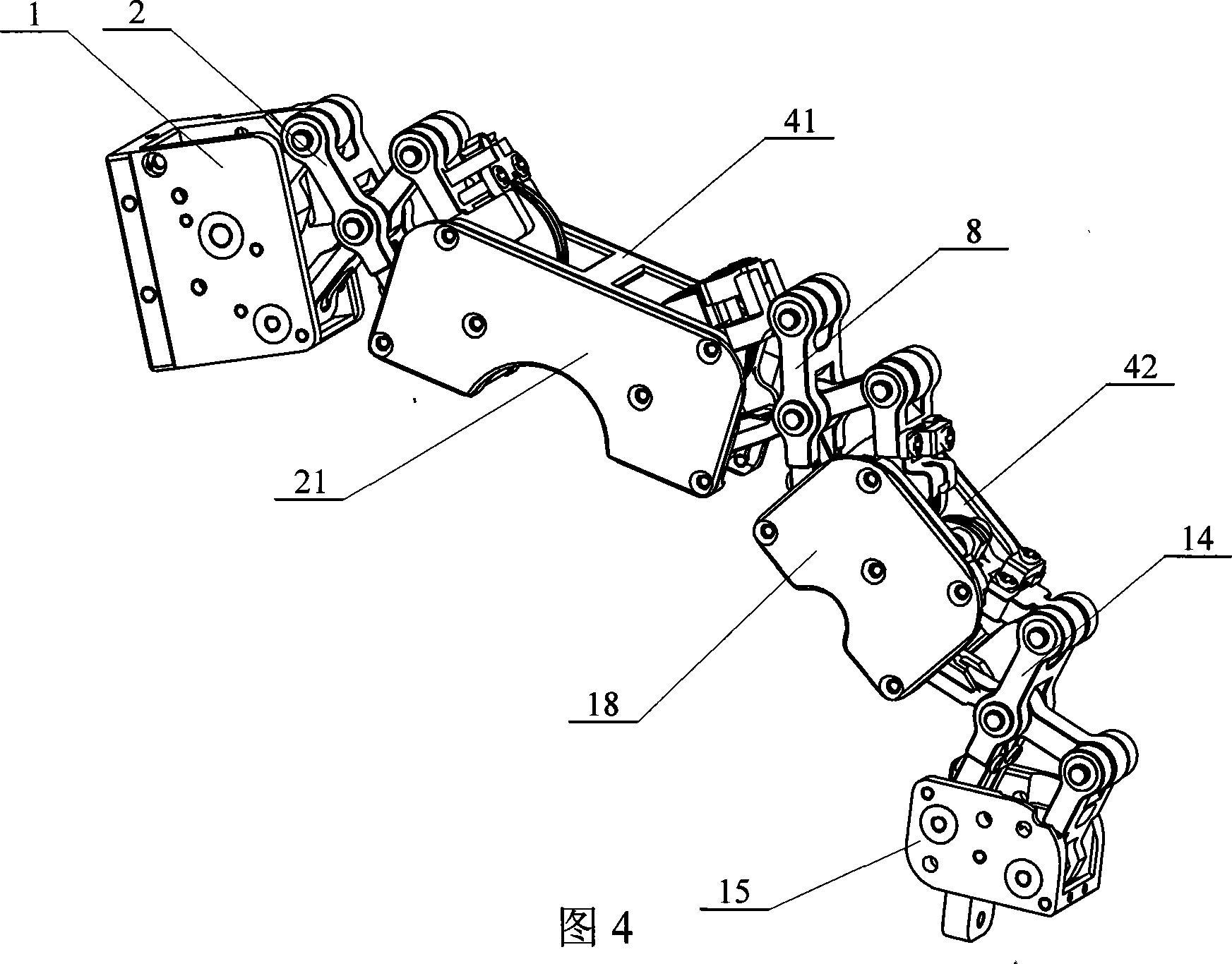

[0006] Specific implementation mode one: (see figure 1 ~ Fig. 4) present embodiment is by the first frame 1, the second frame 41, the 3rd frame 42, two first connecting plates 18, two second connecting plates 21, fingertip interface 15, the first parallel The quadrilateral linkage mechanism 2, the second parallelogram linkage mechanism 8, the third parallelogram linkage mechanism 14, the first wire rope transmission mechanism 5, and the second wire rope transmission mechanism 11 are composed of two first connecting plates 18 respectively arranged on the second wire rope transmission mechanism. On both sides of the three frame 42, two second connecting plates 21 are respectively arranged on both sides of the second frame 41, and the first parallelogram linkage mechanism 2 is composed of the first connecting rod 2-1, the second Connecting rod 2-2, the 3rd connecting rod 2-3 and the 4th connecting rod 2-4 form, and the second parallelogram linkage mechanism 8 is made up of No. 1 ...

specific Embodiment approach 2

[0008] Specific implementation mode two: (see figure 1 ~ FIG. 4 ) The transmission ratio of the first wire rope transmission mechanism 5 in this embodiment is 1:1.4, and the transmission ratio of the second wire rope transmission mechanism 11 is 1.4:1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: (see figure 1 ~ Fig. 4) The first frame 1, the second frame 41, the third frame 42, the two first connecting plates 18, the two second connecting plates 21, the fingertip interface 15, the first The materials of the parallelogram linkage 2 , the second parallelogram linkage 8 and the third parallelogram linkage 14 are all LC4. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com