Steel bar derusting machine

A technology for derusting machines and steel bars, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., to achieve the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

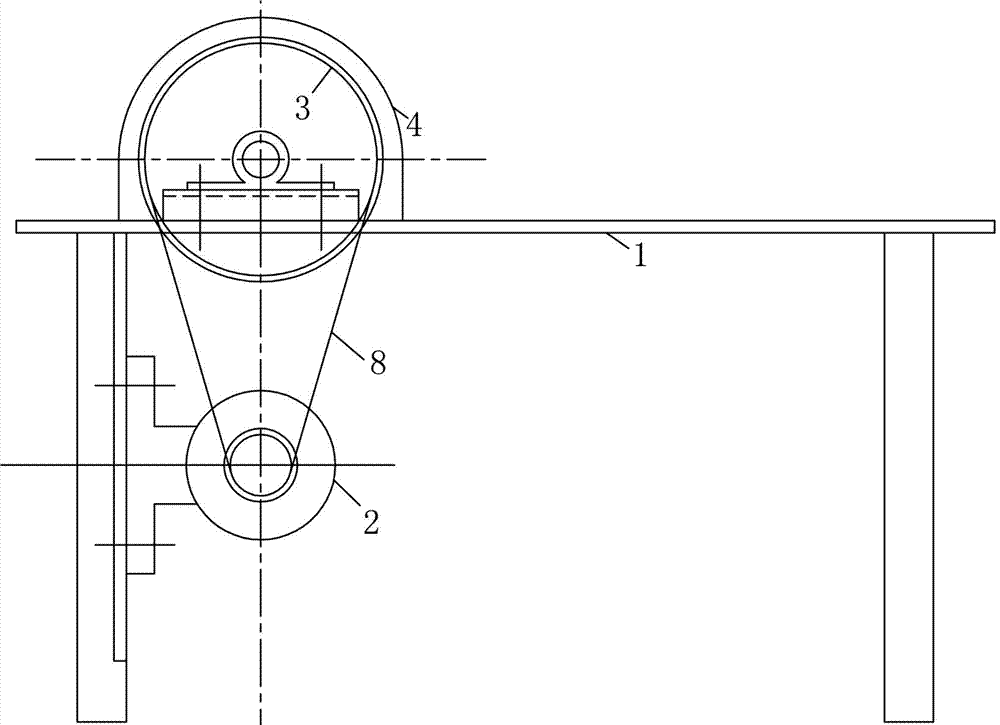

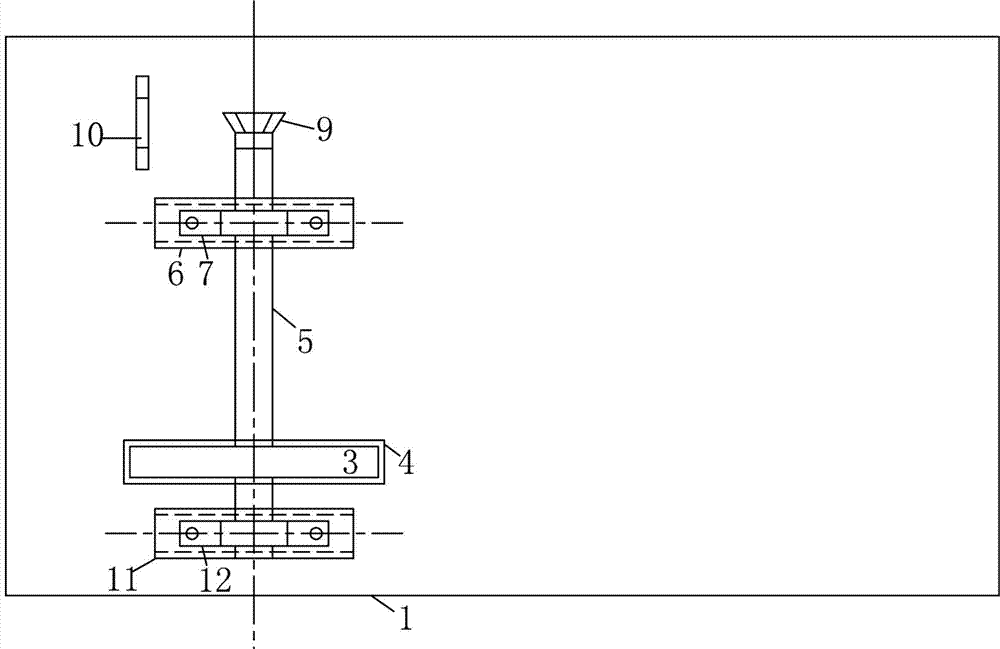

[0009] The structure of the present invention is as figure 1 Shown: a steel bar derusting machine, including a working platform 1, a motor 2 installed on the foot of the working platform 1, one end of a belt 8 cooperates with the motor 2, and the other end is installed on the pulley 3, the pulley 3 is connected with the rotating shaft 5, and the rotating shaft 5 is matched with the front-end bearing 7 and the rear-end bearing 12, the front-end bearing 7 is installed in the front fixed frame 6, the rear-end bearing 12 is installed in the rear fixed frame 11, the wire wheel 9 is connected with the rotating shaft 5, and on the working platform 1 A feeding port 10 is provided. A protective cover 4 is installed on the belt pulley 3 to ensure safe operation.

[0010] The working process of the present invention is as follows: start the motor 2, drive the belt pulley 3 to rotate through the belt 8, the belt pulley 3 transmits power to the steel wire wheel 9 at the end of the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com