Three-dimensional printer and three-dimensional printing method

A three-dimensional printer and three-dimensional printing technology, applied in the field of three-dimensional imaging, can solve the problems of high cost, easy to be damaged, and deformation of guide rods, and achieve the effects of improving stability, avoiding pollution, and avoiding misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

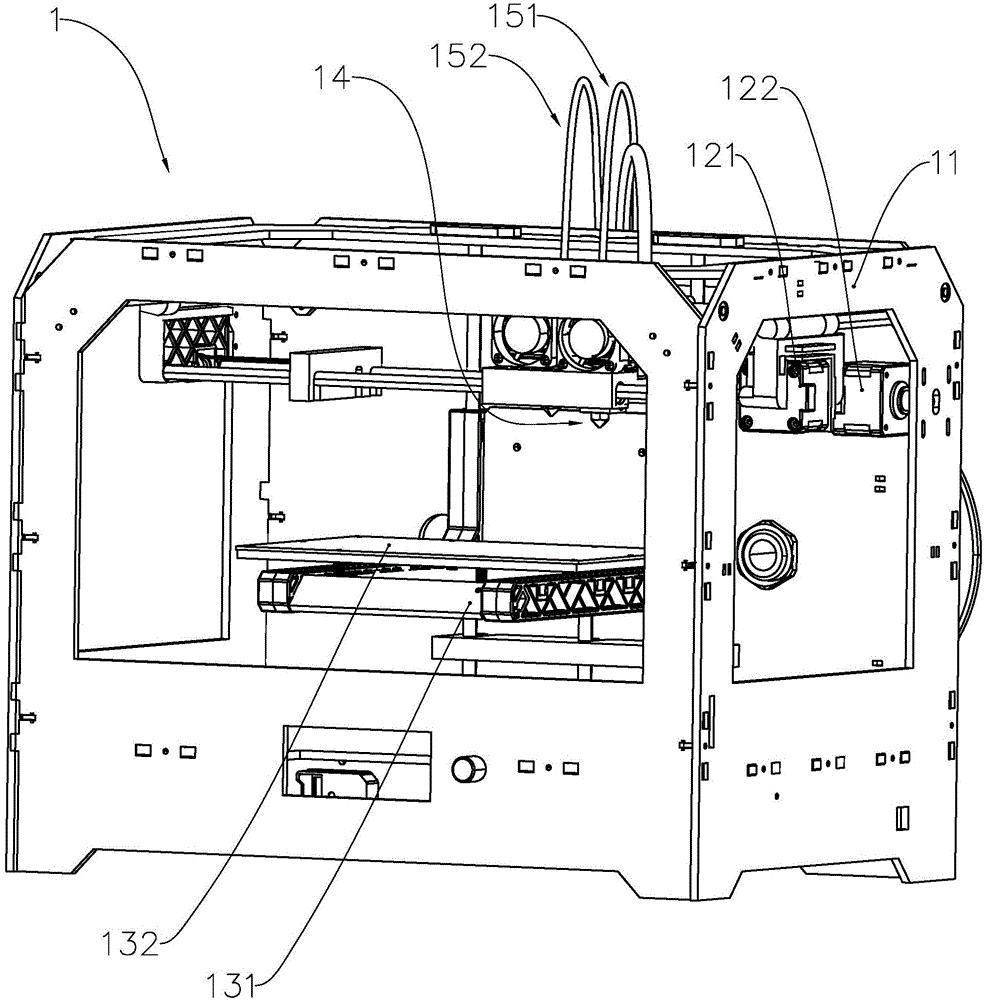

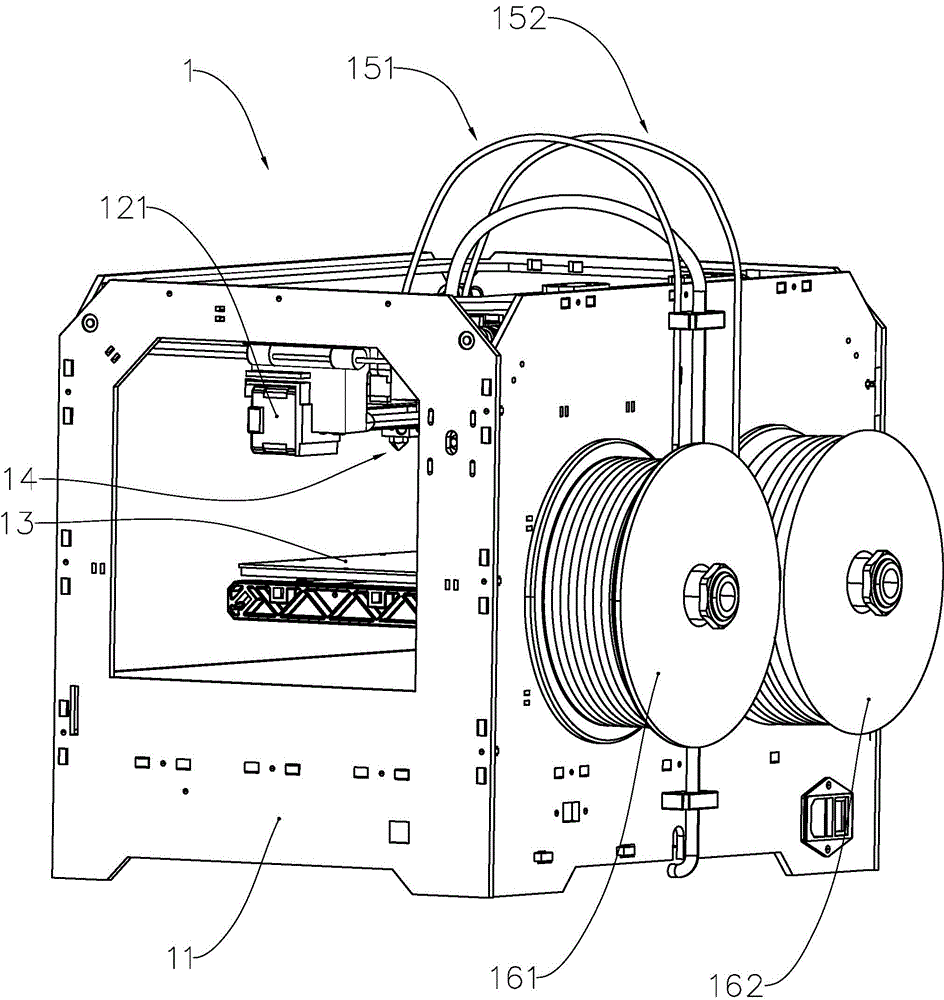

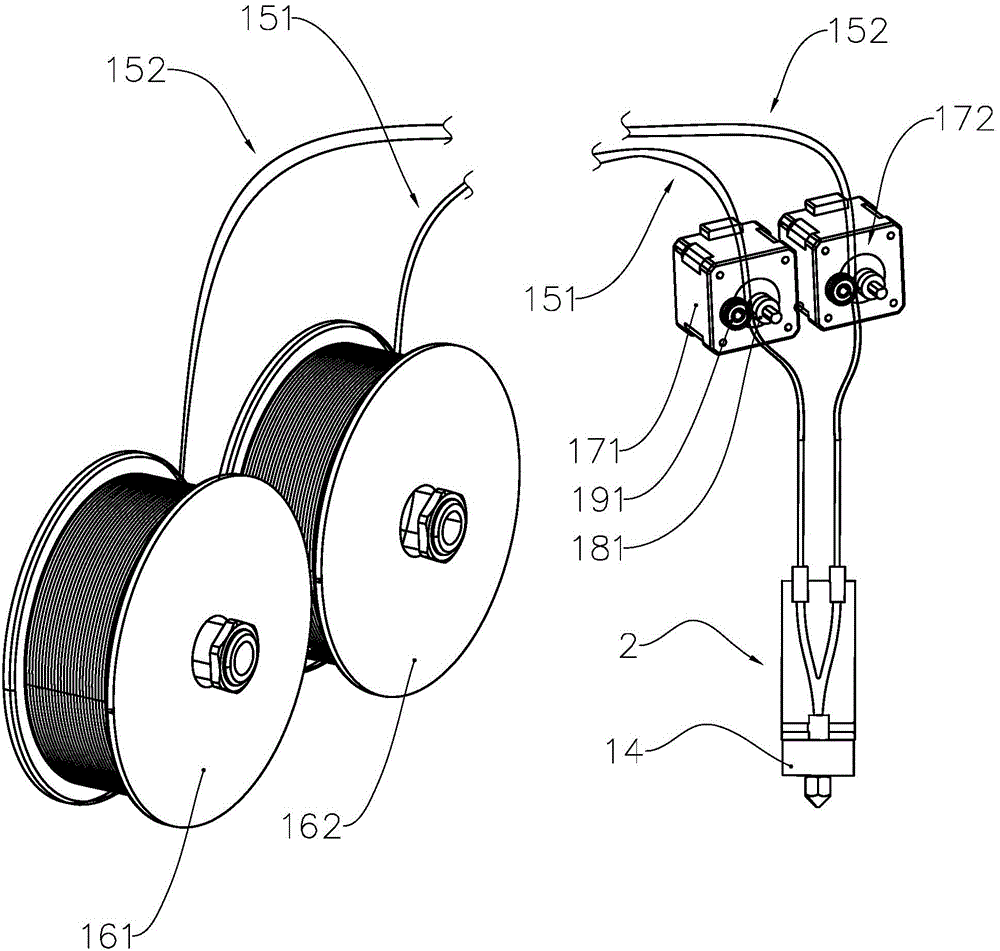

[0034] refer to figure 1 and figure 2 , figure 1 and figure 2 It is a structural diagram of the three-dimensional printer 1 under different viewing angles. The three-dimensional printer 1 includes a housing 11, the housing 11 encloses a cavity for three-dimensional imaging, and an X-axis moving motor 121, a Y-axis moving motor 122, and a Z-axis moving motor (not marked) are installed in the cavity, and Z The shaft moving motor is installed at the bottom of the cavity, and the Z-axis moving motor is connected with a screw rod. A guide rod is also installed on the bottom wall of the cavity, and a Z-axis moving bracket 131 is installed on the guiding rod. On the Z-axis moving bracket 131 is provided with a forming seat 132, because the Z-axis moving bracket 131 is threadedly engaged with the screw, so when the Z-axis moving motor works, the screw will be driven to rotate, and then the forming seat 132 will move in the Z-axis direction under the drive of the Z-axis moving mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com