(6 plus 1)-dimension force feedback sensing device

A transfer wheel and elbow technology, which is applied to manipulators, joints, program-controlled manipulators, etc., can solve the problems of limited force feedback output capability, small force feedback dimension, and high price, and achieve large feedback force, compact structure, and manufacturing low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

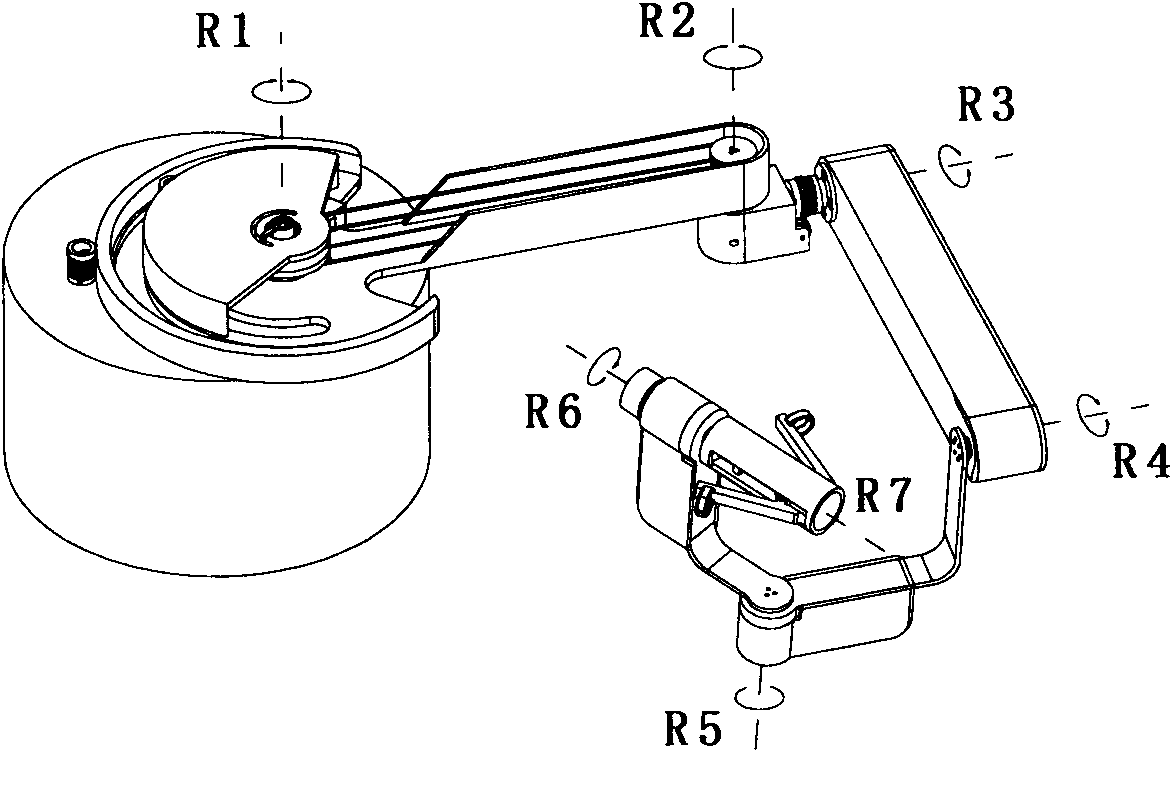

[0019] figure 1 Shown is a schematic diagram of the overall structure of the present invention. The illustrated R1, R2, R3, R4, R5, R6 and R7 describe the 6+1 joints of the present invention, wherein R1, R2 and R3 can determine the space of the tactile device Position, R4, R5, R6 constitute the wrist structure where the three axes meet, and R7 is the opening and closing joint. The relevant joints will be introduced in detail later.

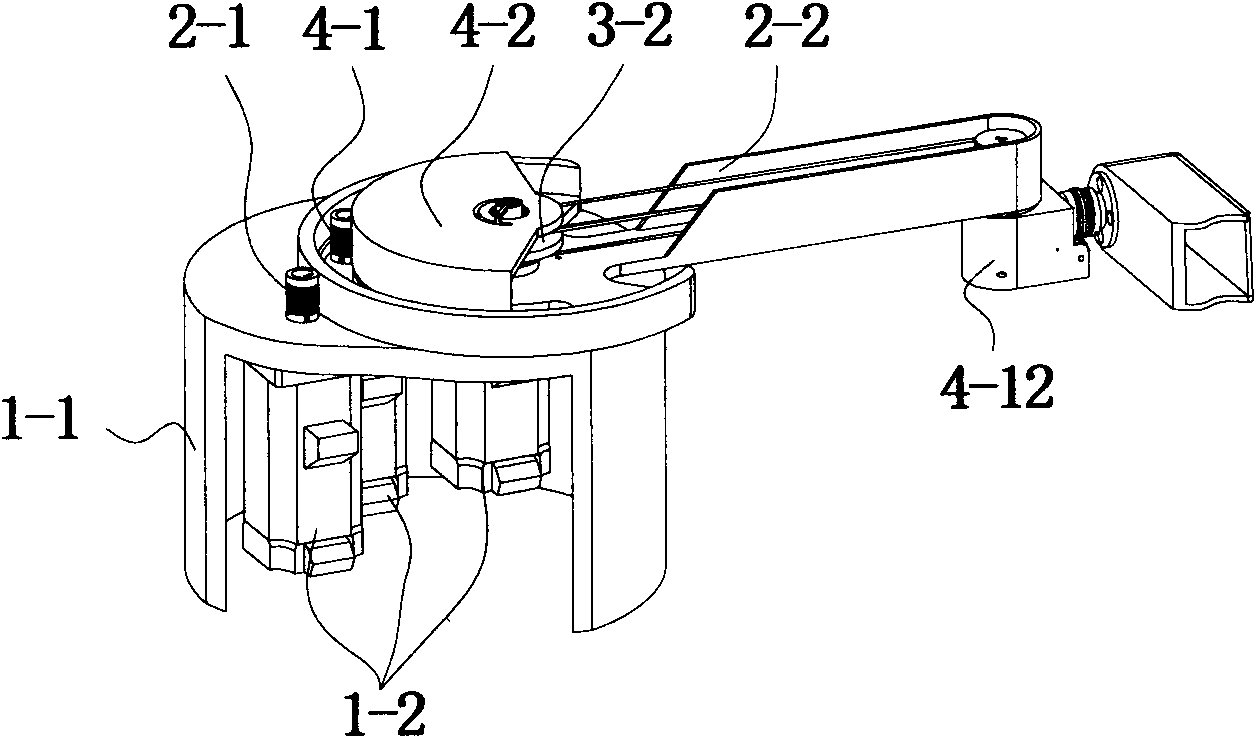

[0020] The base mechanism 1-1 is a box for supporting the whole touch device, such as figure 2 As shown, the controller of the tactile device and the motor 1-2, motor 1-3, and motor 1-4 of the rod part are arranged inside, and the three motors are arranged asymmetrically. The motor 1-2, the motor 1-3, and the motor 1-4 are respectively fixed on the base mechanism 1-1 by screws. The base mechanism 1-1 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com