Motor built-in type modularized prosthetic finger with self-locking function

A built-in, modular technology, applied in the direction of prosthesis, medical science, artificial arm, etc., can solve the problems that a single finger cannot be controlled independently, does not have self-locking function, and the degree of modularization is not high, and achieves active loading of fingertips and Large passive bearing capacity, convenient disassembly and maintenance, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

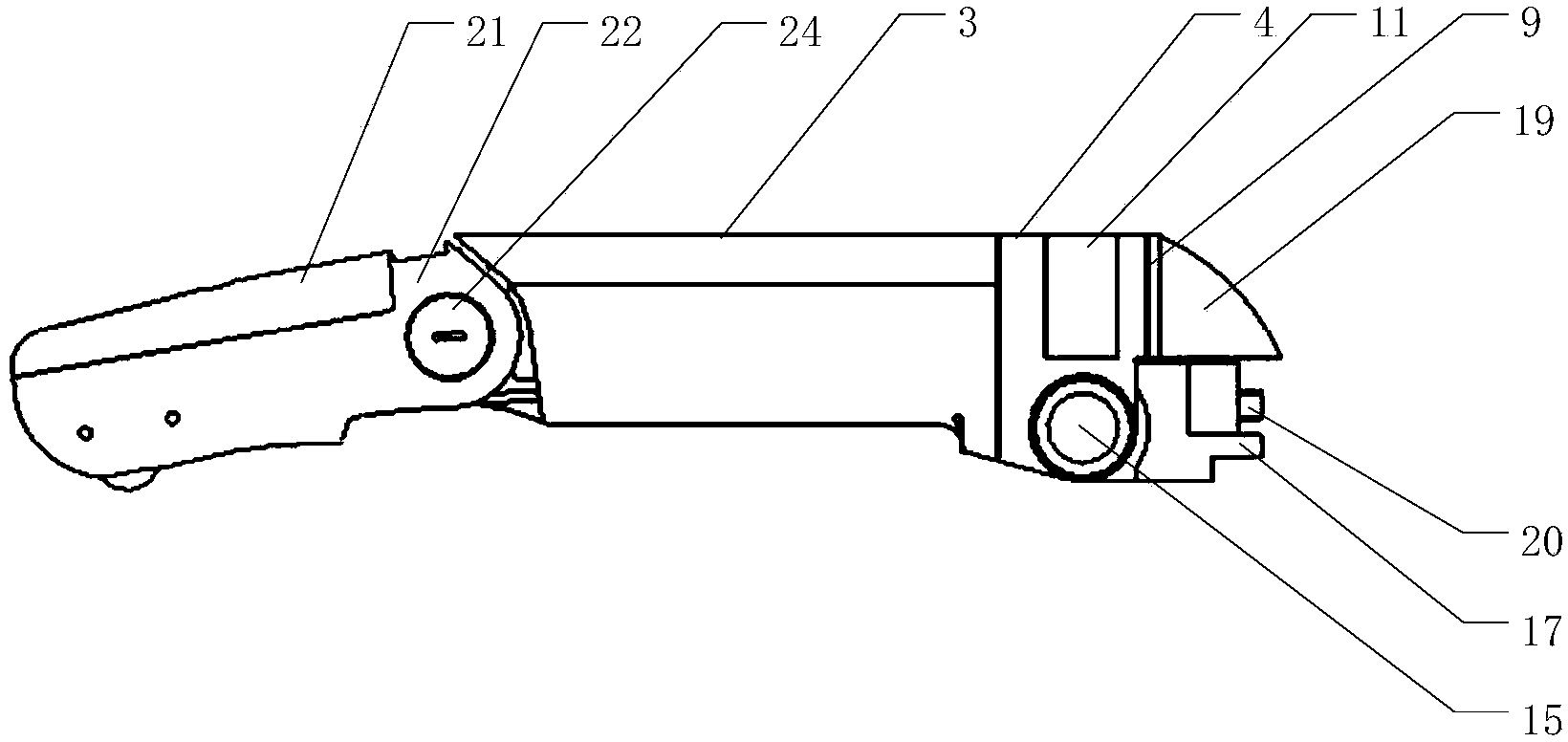

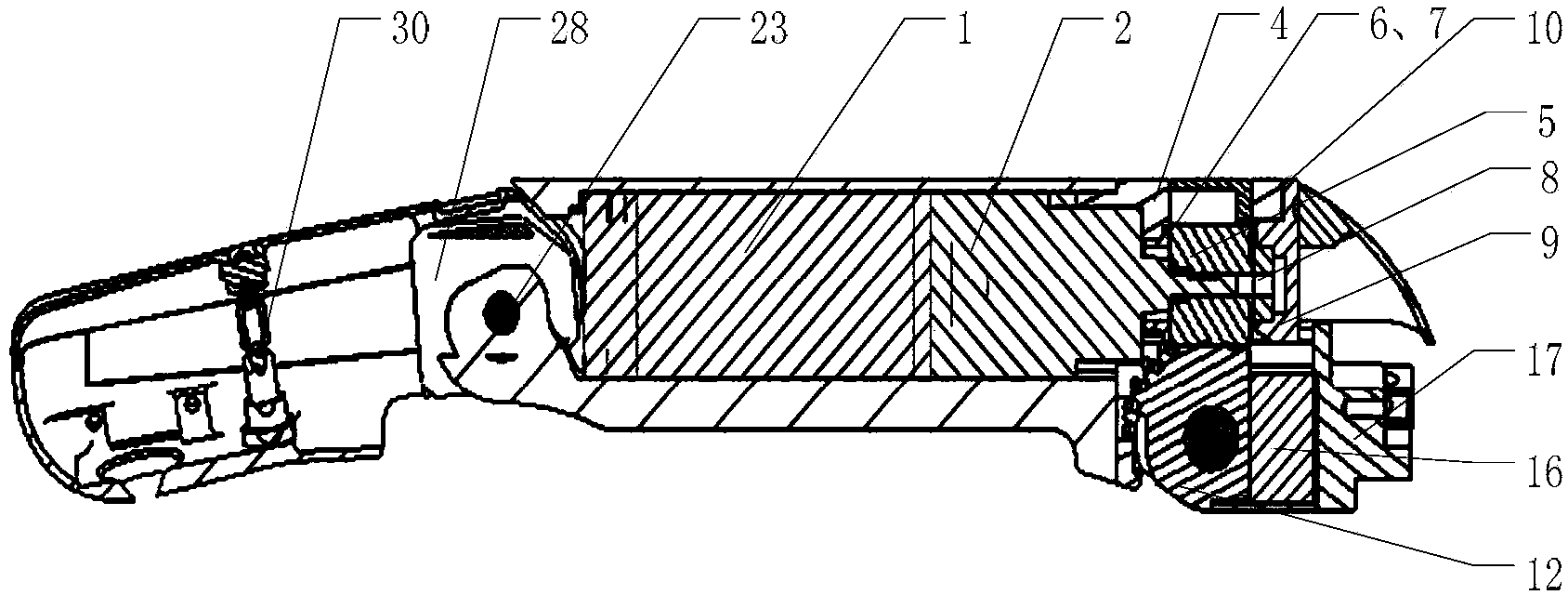

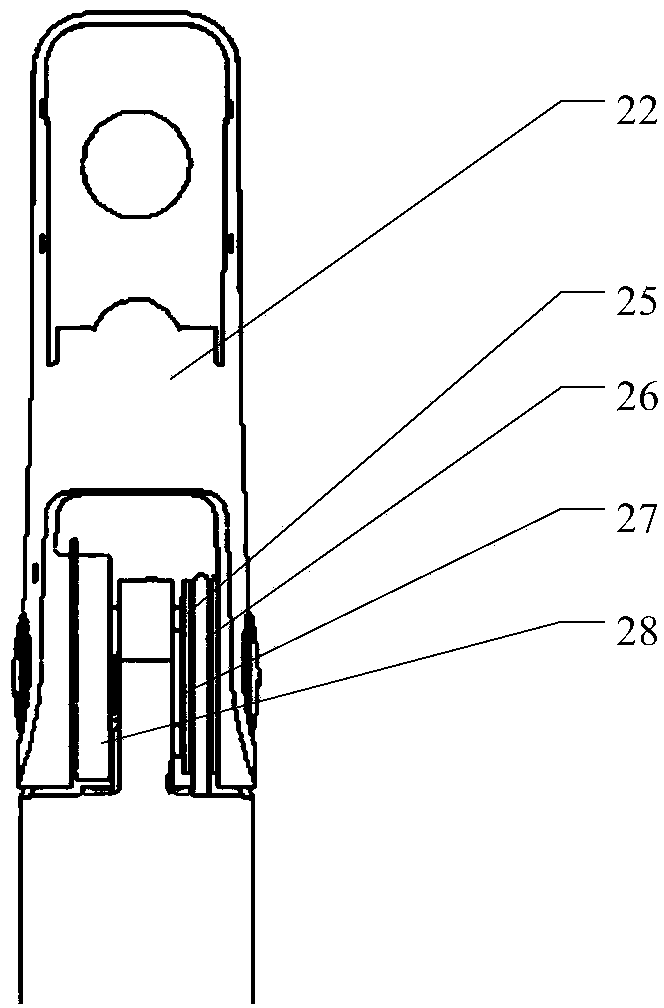

[0008] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment, the motor-built-in modular artificial finger with self-locking function described in this embodiment includes a proximal knuckle and a distal knuckle, and the proximal knuckle includes a motor 1, a reducer 2, a proximal knuckle shell 3, The rotating frame 4, the worm 5, the worm shaft 8, the end cover 9, the worm wheel 12, the first joint wire wheel, the base joint shaft 15, the base joint base 17 and the pressure plate 20, the speed reducer 2 is fixedly installed on the rotating frame 4 , the proximal knuckle shell 3 is installed on the rotating frame 4, the output shaft of the motor 1 is connected to one end of the worm 5 through the reducer 2, the other end of the worm 5 is connected to the end cover 9 through the worm shaft 8, and the base joint base 17 is passed through The base joint shaft 15 is connected with the rotating frame 4, the worm gear 12 is sleeved on the base join...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 2 Describe this embodiment, the proximal knuckle of the motor-built-in modular prosthetic finger with self-locking function described in this embodiment also includes a worm washer 6 and a plastic sleeve 7, and one end of the worm 5 passes through the worm washer 6 and the plastic sleeve The barrel 7 is connected to the output shaft of the speed reducer 2 .

[0011] The technical effect of this embodiment is: such an arrangement can effectively bear the axial force of the worm, and by optimizing the material of the worm washer 6, the coefficient of friction between it and the plastic sleeve 7 can be reduced, thereby reducing friction loss. The worm spacer 6 and the plastic sleeve 7 can also be replaced by thrust bearings, so that no friction loss can be guaranteed, but the size is slightly larger. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 2 To illustrate this embodiment, an adjusting gasket 10 is provided between the rotating frame 4 and the end cover 9 of the motor built-in modular prosthetic finger with self-locking function in this embodiment.

[0013] The technical effect of this embodiment is: so arranged, the gasket 10 is used to adjust the degree to which the worm screw 5 compresses the plastic sleeve 7; the worm washer 6 and the plastic sleeve 7 of the worm 5 shafting part can also be replaced by thrust bearings, To resist the axial force of the worm 5. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com