Steel tube rust removal device with automatic paint spraying function

A technology of automatic spray painting and steel pipe, which is applied to spray devices, machine tools with surface polishing, machine tools designed for grinding the rotating surface of workpieces, etc. Low and other problems, to achieve the effect of preventing the processing time from being too long

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

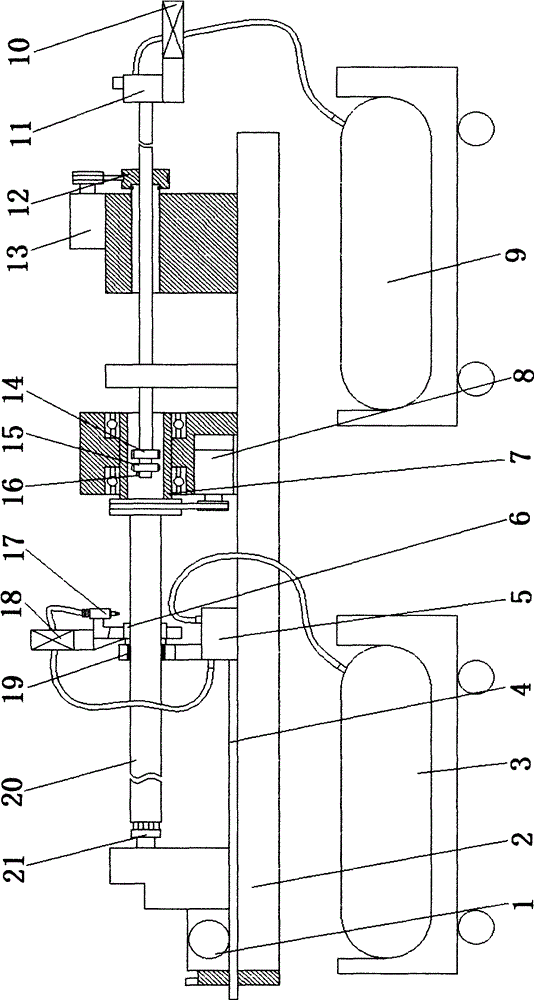

[0013] A steel pipe derusting device with automatic painting function, comprising a frame 2, an inner chuck 21 and a rotary chuck 7 are arranged on the frame 2, and a steel pipe 20 is arranged between the inner chuck 21 and the rotary chuck 7, the The rotary deck 7 is connected to the second motor 8 through a belt, and the rotary deck 7 drives the steel pipe 20 to rotate. A guide rail is provided on the base between the inner chuck 21 and the rotary deck 7, and a belt slide is provided on the guide rail. The first paint pot 5 of the block, the top of the first paint pot 5 is provided with an outer steel wire wheel 19 to remove the rust on the outer wall of the steel pipe 20, the right side of the outer steel wire wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com