Steel pipe derusting machine

A technology for descaling machines and steel pipes, applied in metal processing equipment, manufacturing tools, grinding machines, etc., can solve problems affecting the descaling effect of steel pipes, low production efficiency, complex structure, etc., and achieve the effect of ensuring descaling effect and normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

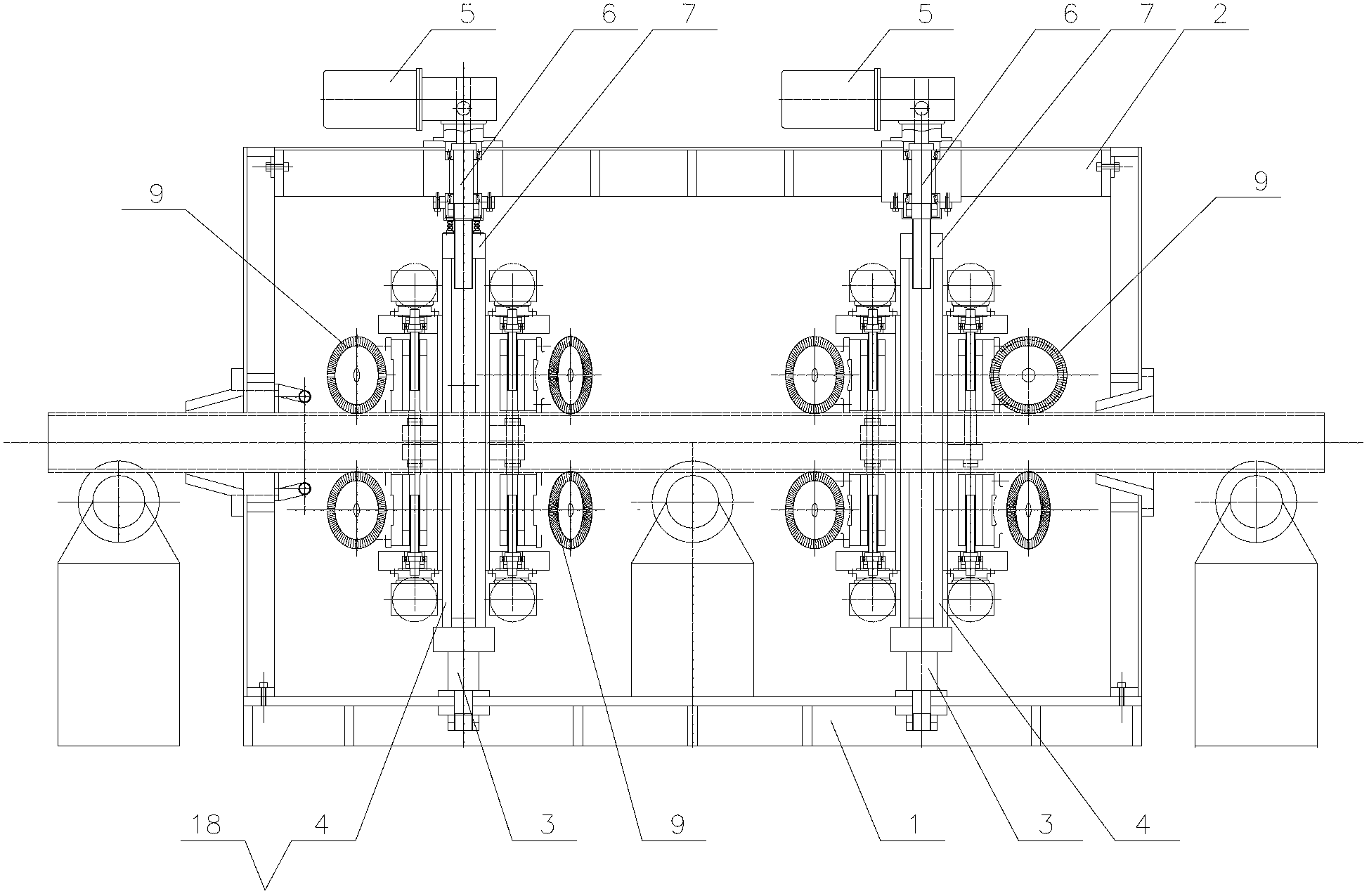

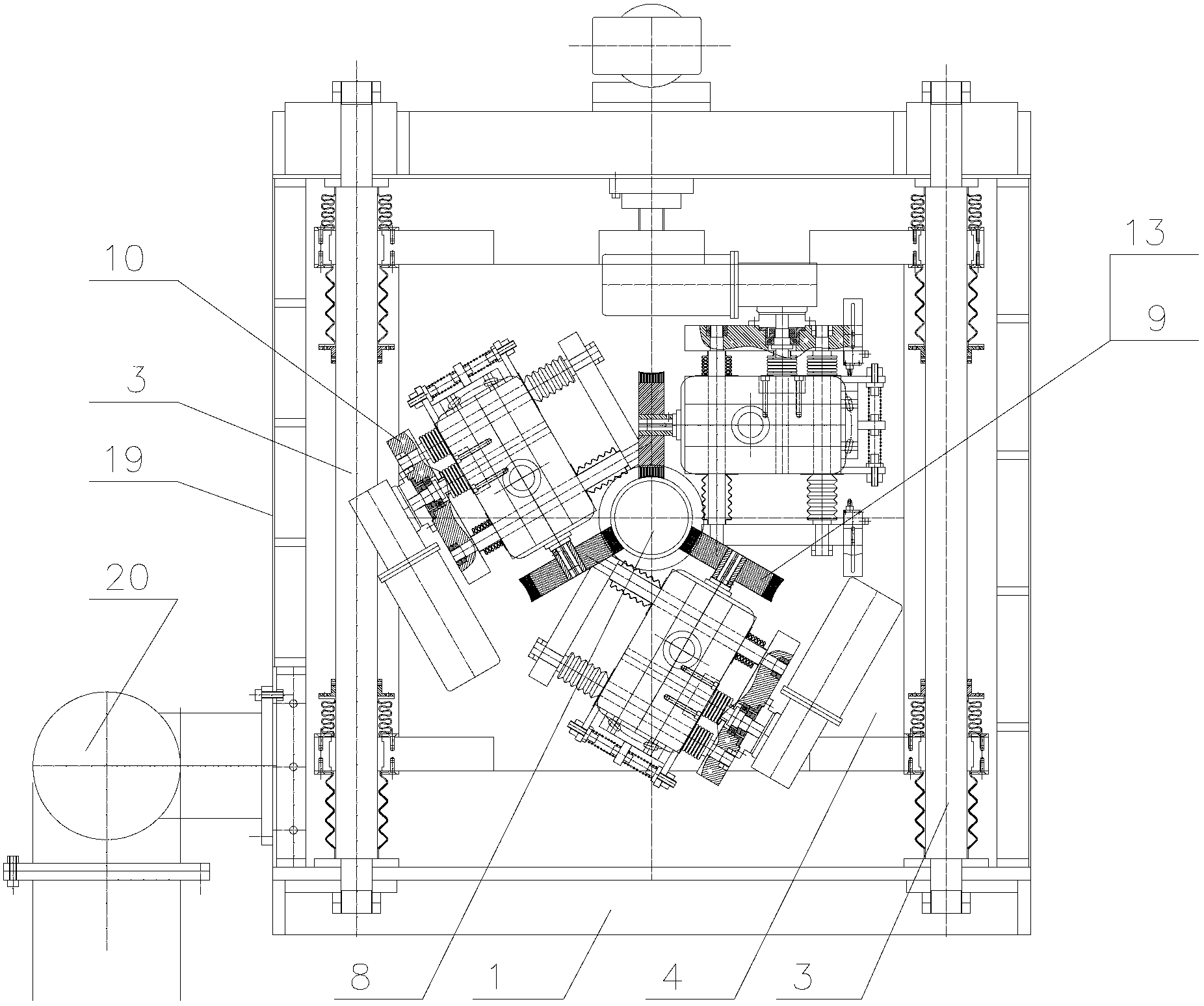

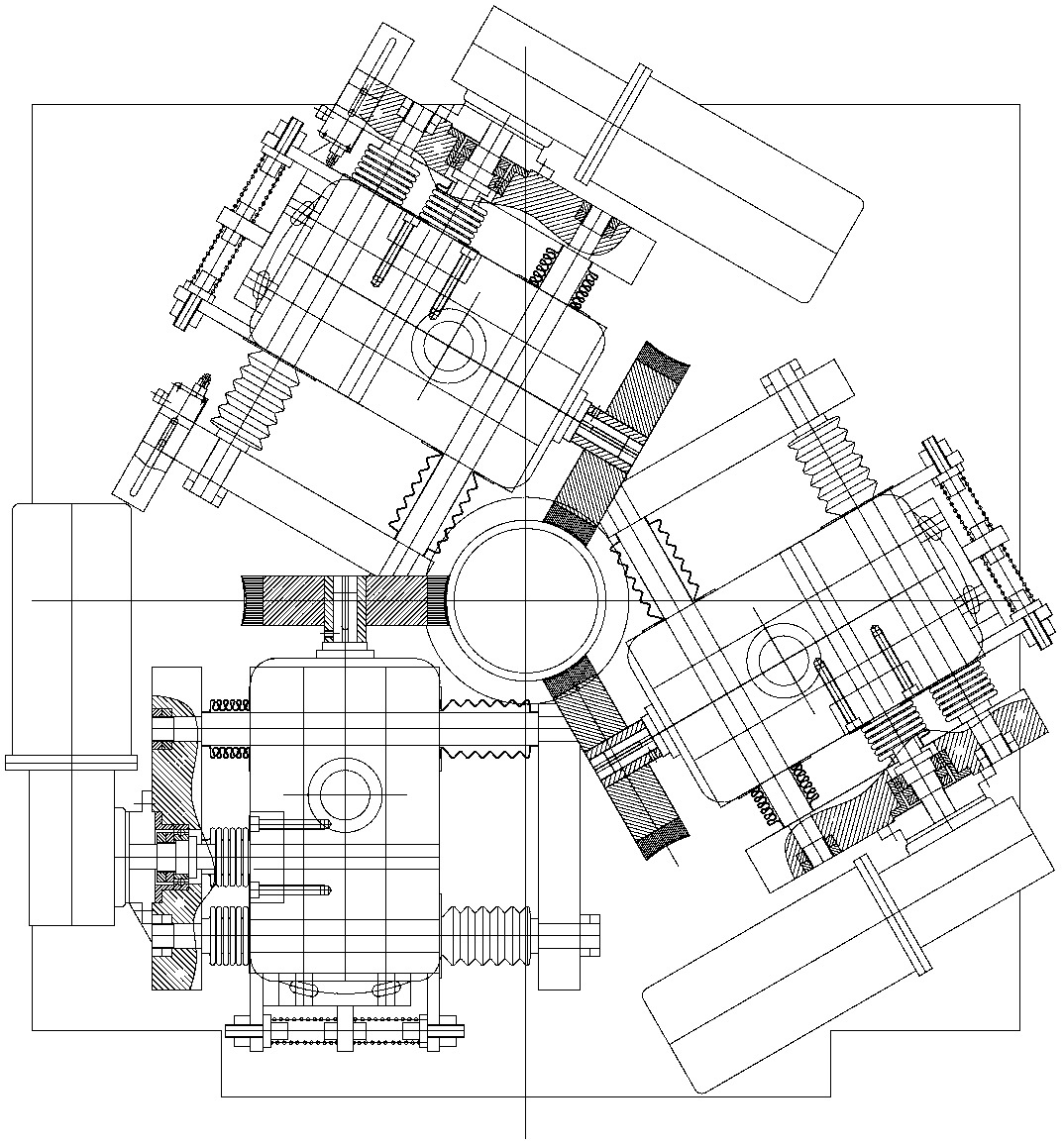

[0021] Attached below figure 1 -8 describes an embodiment of the present invention.

[0022] A steel pipe derusting machine has a base 1 on which a door-shaped bracket 2 is fixed, and two pairs of columns 3 are arranged on the door-shaped bracket 2, and a wall panel 4 is set on each pair of columns 3, The center of the upper end of each wallboard 4 is fixed with a lifting screw nut 7; two lifting adjustment reduction motors 5 and two lifting lead screws 6 are installed on the top of the door-shaped support 2, and the two lifting lead screw 6 upper ends are respectively connected to the corresponding The power output shafts of the two lifting adjustment reduction motors 5 are connected, and the lower ends of the two lifting screw screws 6 are screwed in the corresponding lifting nuts 7 below them. The center of the wallboard 4 has a through hole 8 , and the wire wheel assembly 9 is evenly distributed around the through hole 8 .

[0023] The wallboard 4 is composed of two stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com