Mechanical arm high-angle controllable rotary joint device driven by two steel wire ropes

A technology of steel wire rope and mechanical arm, applied in the field of large-angle controllable rotary joint device of the mechanical arm, to achieve the effect of high transmission efficiency and low friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

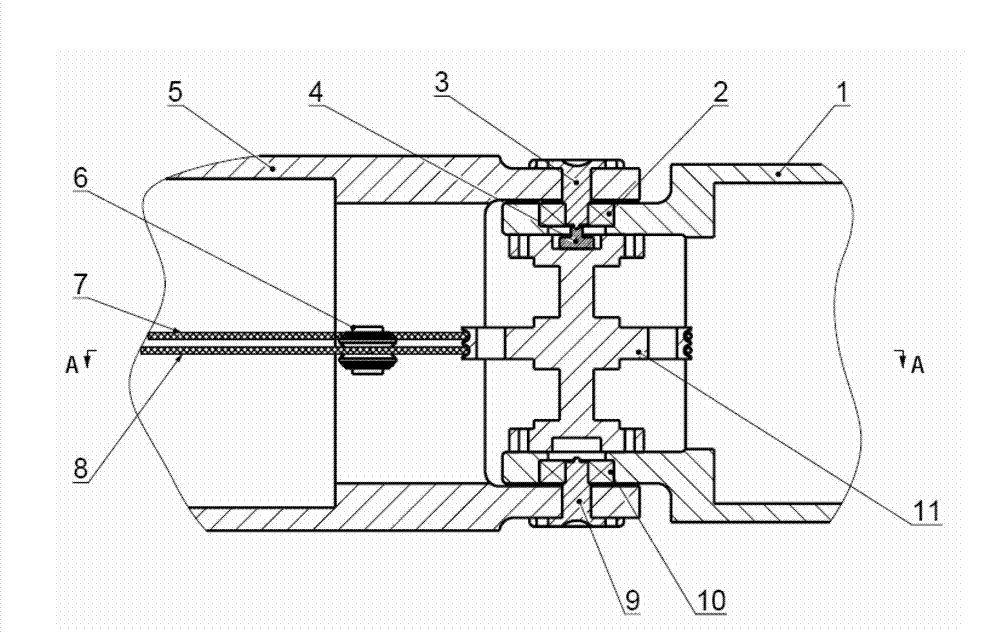

[0031] figure 1 A cross-sectional schematic diagram of the overall structure of the large-angle controllable rotary joint device of the mechanical arm driven by double wire ropes of the present invention is given. Such as figure 1 As shown in , the large-angle controllable rotary joint device of the mechanical arm driven by double wire ropes in this embodiment includes: the front-stage mechanical arm 1, the first bearing 2, the first rotating shaft 3, the angle sensor 4, the rear-stage mechanical arm 5, and the steel wire rope Pretensioning device 6, left-handed steel wire rope 7, right-handed steel wire rope 8, second rotating shaft 9, second bearing 10, steel wire roulette 11.

[0032] The non-output shaft end of the angle sensor 4 is placed at the bottom of the cavity of the flange at the upper end of the rotating shaft of the wire roulette 11, and the output shaft of the angle sensor 4 is adjusted to maintain a coaxial relationship with the rotating shaft of the wire roul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com