Steel pipe polishing and painting robot

A robot and painting technology, applied in the direction of grinding machines, coatings, portable grinding beds, etc., can solve the problems of uneven paint application, high work intensity, low efficiency, etc., and achieve the effect of ensuring uniformity, protecting the environment, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

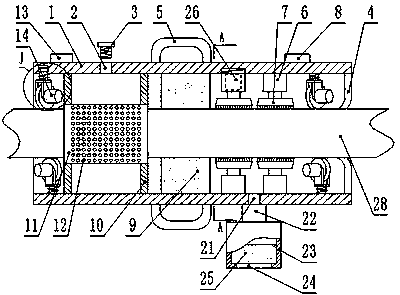

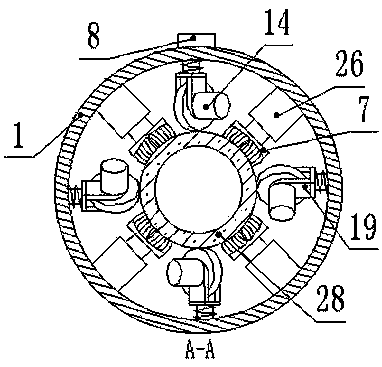

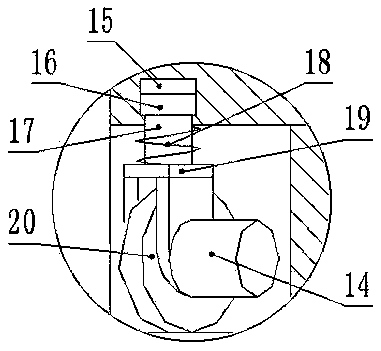

[0019] Such as Figure 1-4 As shown, a steel pipe grinding and painting robot includes a cylindrical shell 1, a dust removal device, a painting device and a driving device. The sponge layer 9, the dust outlet hole 21, the suction fan 22, the dust storage housing 23, the square hole 24, the sponge block 25 and the battery 26 are formed. One side of the cylindrical housing 1 is provided with a retaining ring 4, and the retaining ring 4 is vertically arranged with the cylindrical shell 1, and the inner wall of the cylindrical shell 1 is provided with a plurality of grinding shells 6 which are evenly arranged in a ring, and one end of the grinding shell 6 is screwed with the inner wall of the cylindrical shell 1. Then, the inside of the grinding housing 6 is provided with a battery 26, and the other end of the grinding housing 6 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com