Electric automatic take-up device

The technology of a wire take-up device and a wire winding device is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc. It can solve the problems of damage to the cable sheath, occupying space for winding wires, inconvenient use, etc., to prevent The effect of damage, mobile storage and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be described in further detail below with reference to the accompanying drawings.

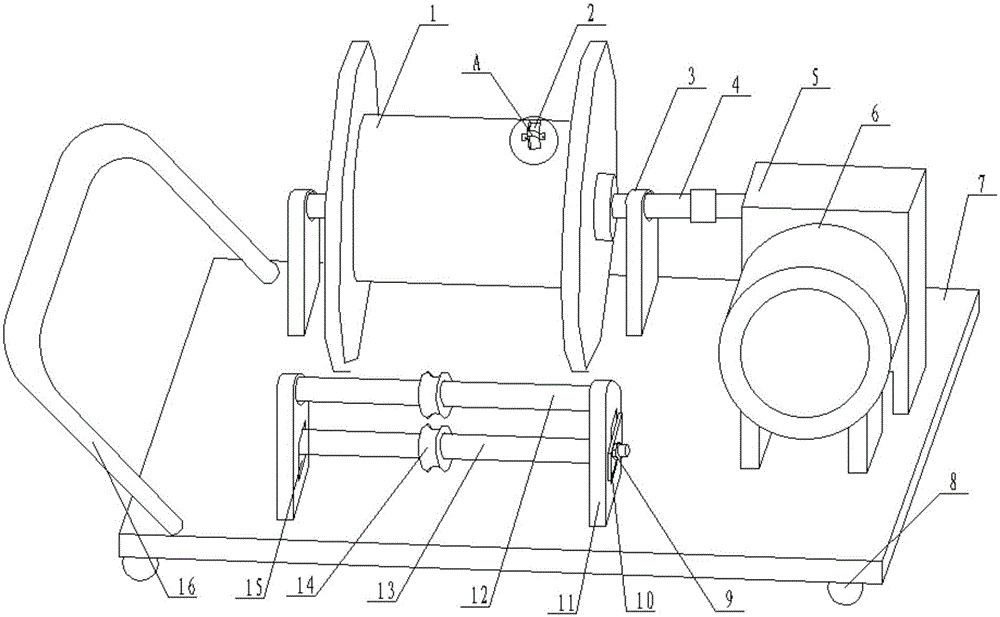

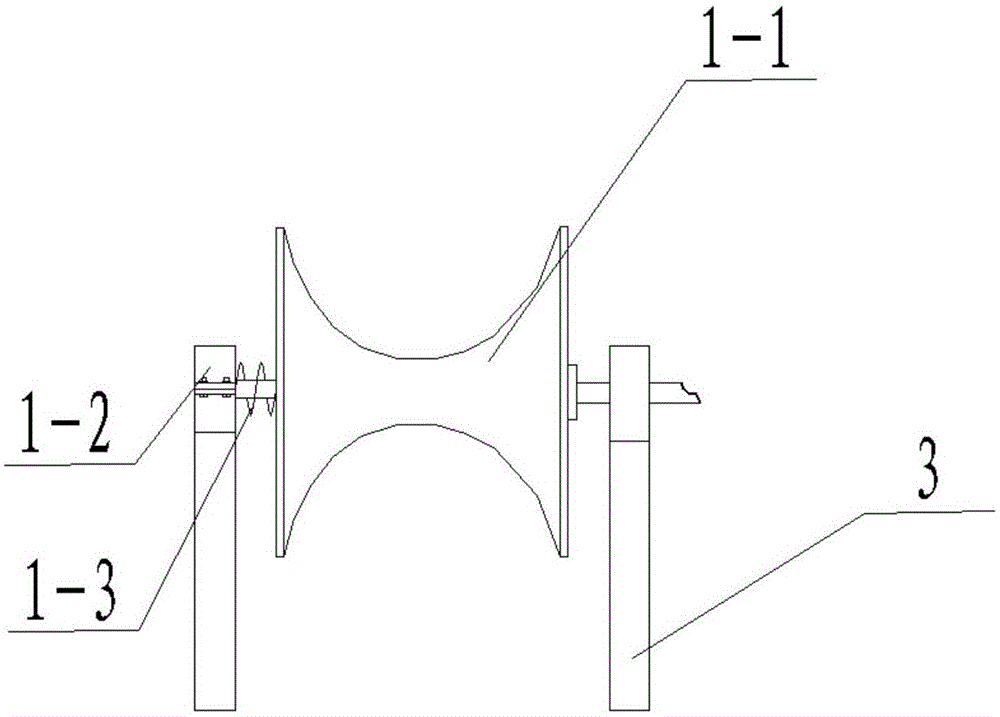

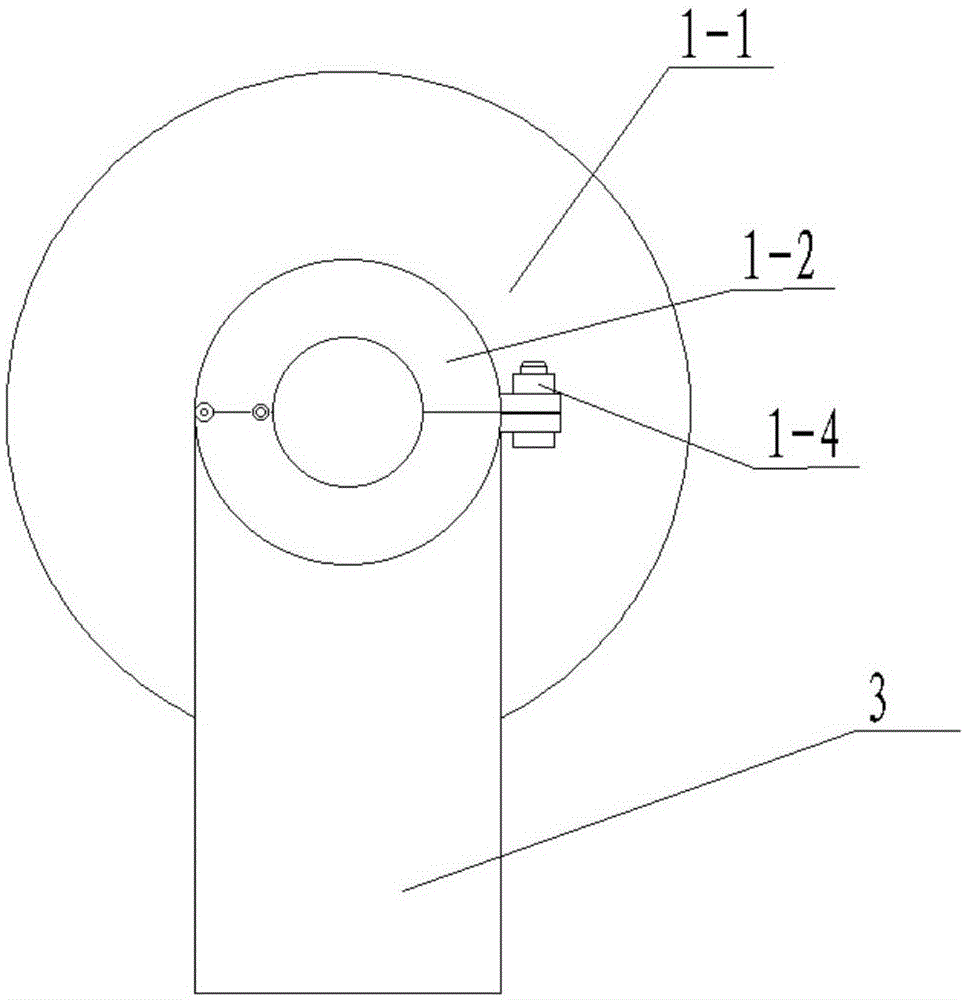

[0020] Such as figure 1 , figure 2 , image 3 and Figure 4 The automatic take-up device for electric power shown includes a chassis 7, a motor 6 and a reducer 5 are fixed above the chassis 7, the motor 6 is connected to the reducer 5, the output end of the reducer 5 is connected to the rotating shaft 4, and the other end of the rotating shaft 4 A winding device 1 and a support seat 3 are provided, the winding device 1 is installed on the rotating shaft 4, the rotating shaft 4 is installed on the supporting seat 3, the supporting seat 3 is fixed on the chassis 7, and one side of the winding device 1 is provided with Cable regularization device, cable regularization device is fixed on the chassis 7.

[0021] The winding device 1 comprises a winding wheel 1-1 and a connecting sleeve 1-2, the rotating shaft 4 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com