Automatic assembly line of reverser

An assembly line and commutator technology, applied in other manufacturing equipment/tools, metal processing machine parts, metal processing, etc., can solve problems such as backward automation equipment, high work intensity, and large personnel mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention is further described:

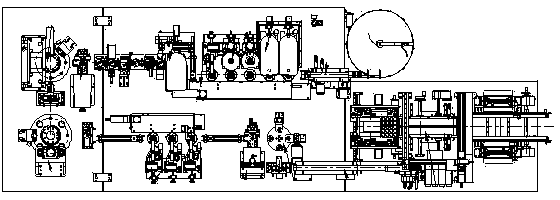

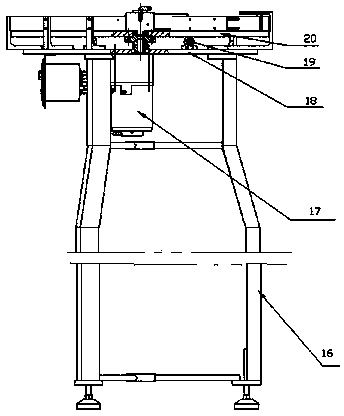

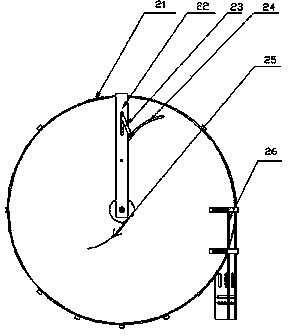

[0032] Such as figure 1 Shown is the plane layout of the automatic assembly line of the commutator. The working sequence is as follows: manually put the blank workpiece into the automatic rotary feeding machine of the disc, and send the product to the belt line with the rotation of the disc, and grab it through the lifting and translation of the electric cylinder The mechanism puts the product into the polishing process. After each product is polished by the abrasive belt and the steel wire wheel, it enters the reaming process through the delivery slide cylinder. Inner hole detection, good products are sent to the next process, and products with bad inner holes are discharged; after the inner hole inspection is completed, the product enters the hook process after being detected and positioned by the camera; in the hook process, the product needs to be pre-bent three times and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com