Helical tape mixing machine

A ribbon mixer and ribbon technology, applied in mixers, dissolving, chemical instruments and methods, etc., can solve the problems of uneven mixing of materials and high powder content, so as to increase the stirring amount, reduce the powder content, reduce the The effect of contact frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

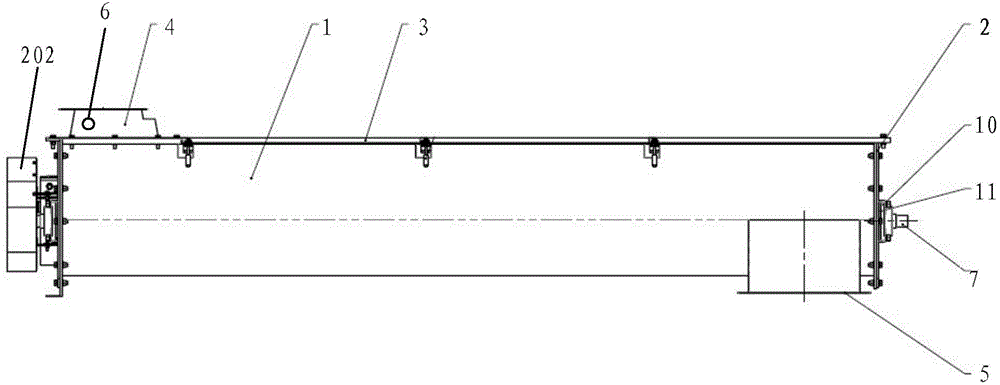

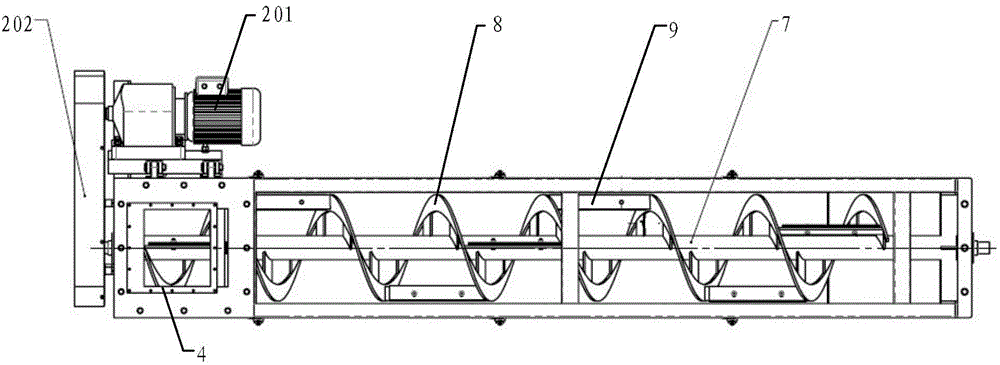

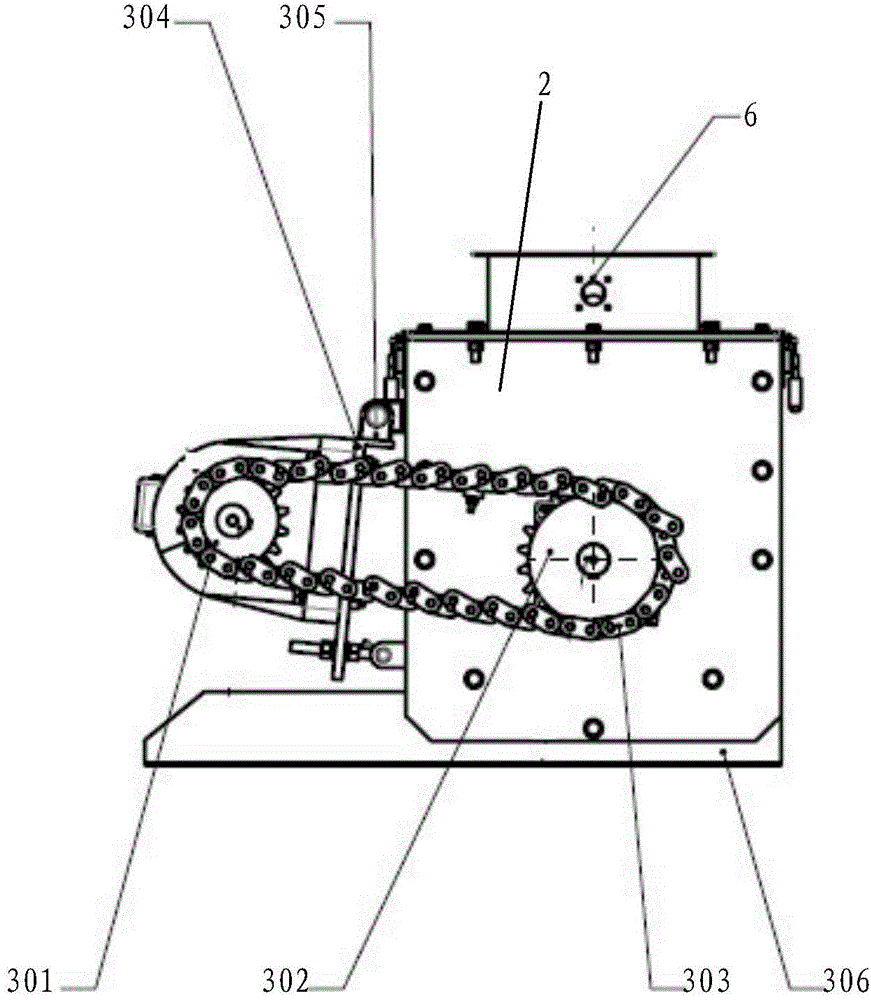

[0032] The embodiments of the present application provide a ribbon mixer, which solves the technical problems of uneven material mixing and high powder content in the prior art when a conveyor is used to transport materials and a mixer is used to agitate the materials. The technical effects of improving the uniformity of the mixed material and reducing the powder content are realized.

[0033] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiment of the present application is as follows:

[0034] The present application provides a ribbon mixer for mixing and transporting the first material and the second material, including:

[0035] A hollow shell, the top end of the hollow shell and the two opposite side ends are both open; the end faces of the two side ends are respectively fixed with a side plate; the end face of the top end is fixed with a cover plate;

[0036] The material inlet and the material outlet ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com