Work roll shifting method used for hot rolled strip steel same-width rolling conditions

A hot-rolled strip and work roll technology, applied in metal rolling, profile control, etc., can solve the problems of serious work roll wear, affecting adjustment ability, uneven wear, etc., to reduce work roll wear, maintain adjustment ability, The effect of dispersing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0018] The object of the present invention is to provide a kind of work roll shifting form design method that makes work roll wear uniform for hot-rolled strip same width rolling condition, the roll shifting position expression of the work roll designed by this method is:

[0019]

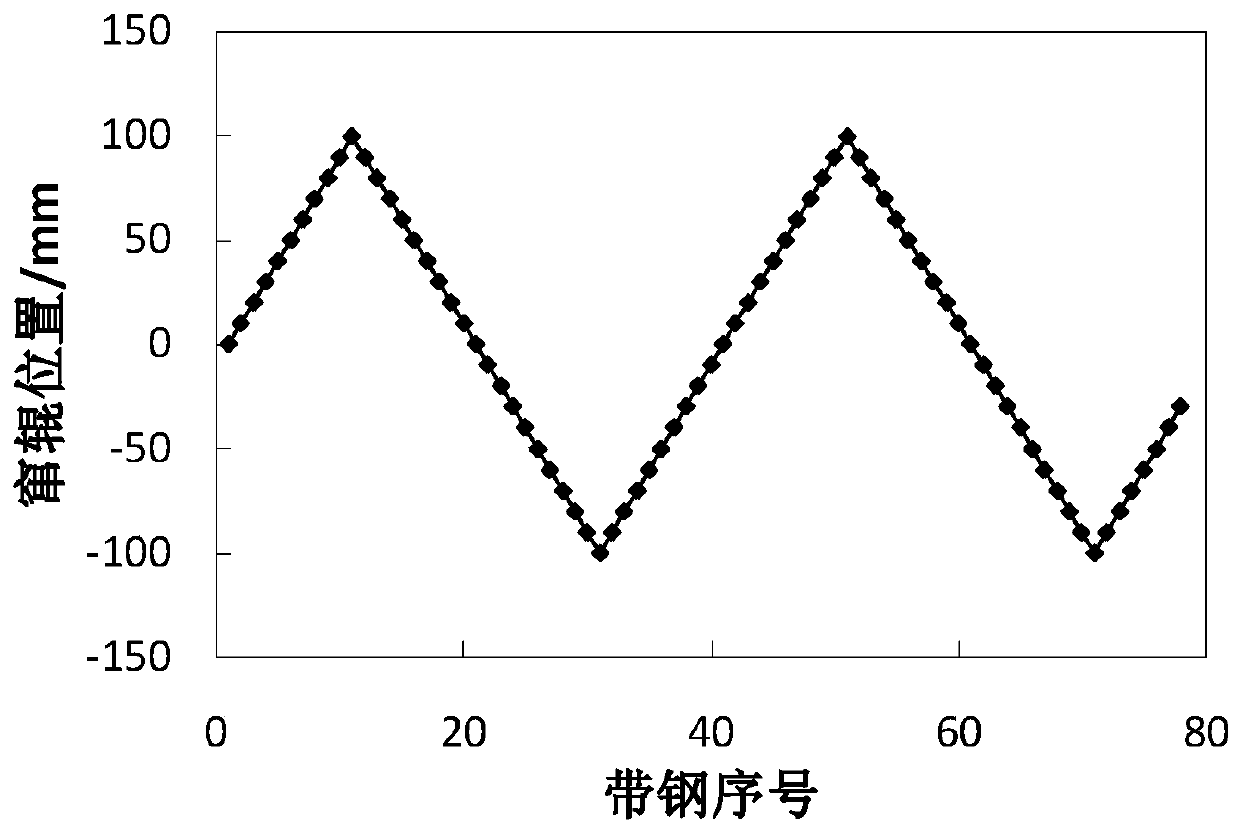

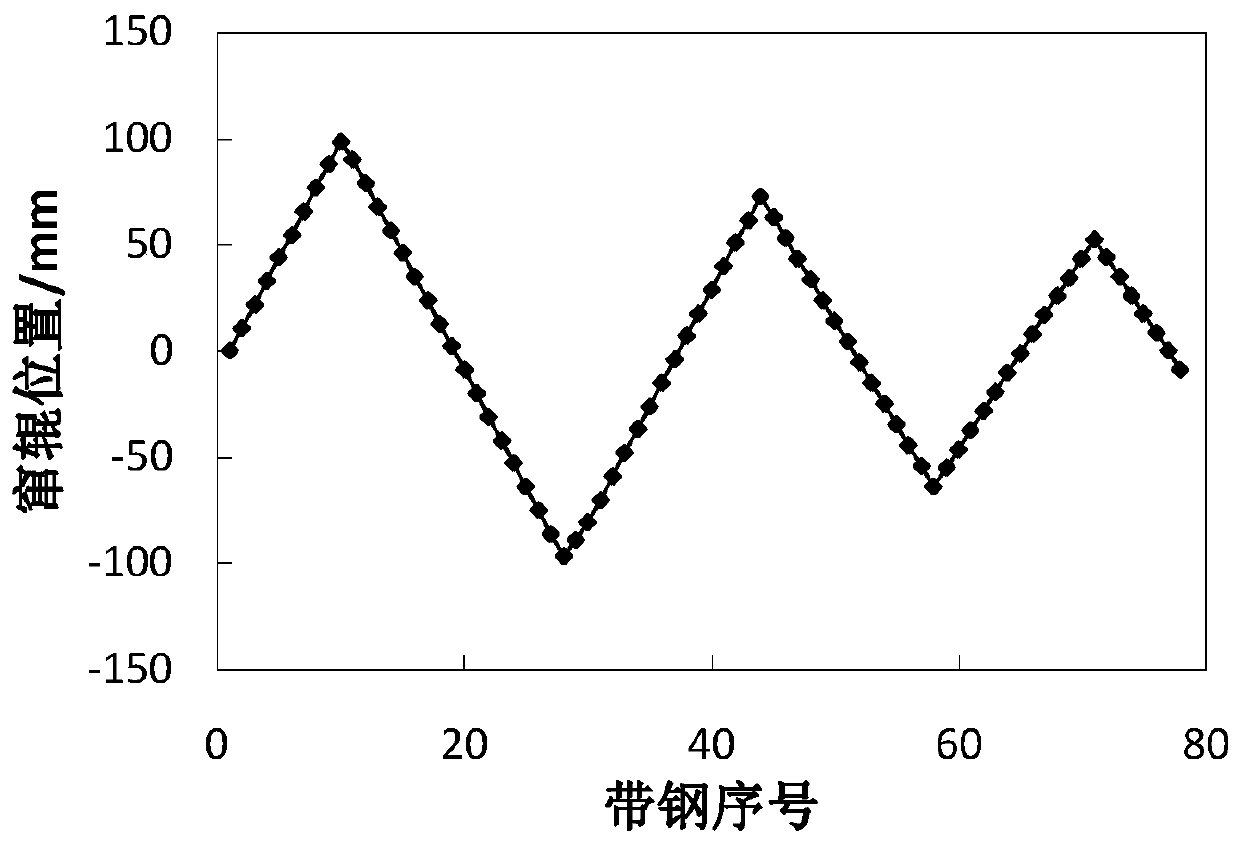

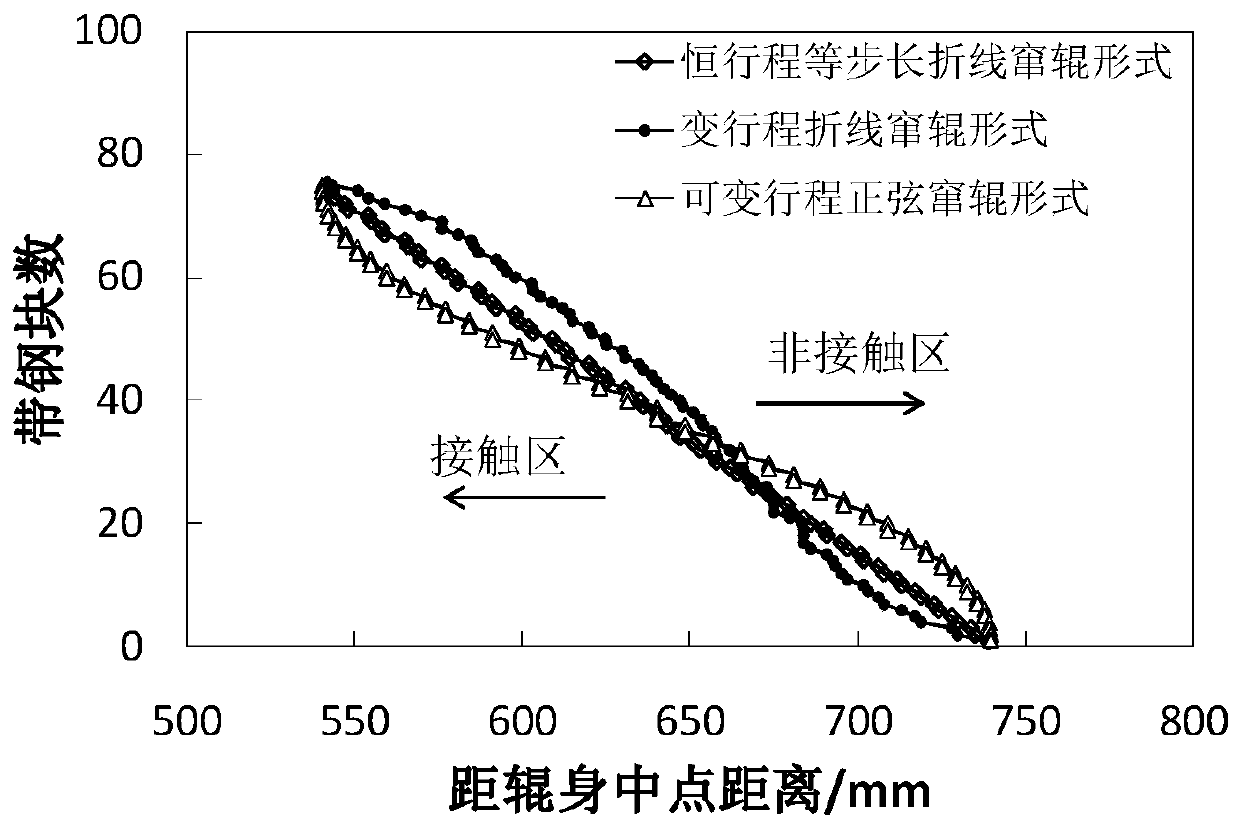

[0020] In the formula, S(n) is the roll shifting position of the work roll when the nth piece of strip is rolled, and the unit is mm; it is defined that the roll shifting position of the work roll to the transmission side is a positive value, and when the roll shifting to the operation side The roll shifting position is a negative value; n is the serial number of the strip, no unit; the serial number of each rolling unit starts from 1, and the serial number of each block increases by 1; A i is the work roll shifting stroke of the i-th rolling unit after the work rolls are on the machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com