Slide bearing, slide bearing unit with same, and motor with the bearing unit

A sliding bearing and radial bearing technology, applied in the field of electric motors, can solve problems such as the inability to stably maintain the bearing accuracy, and achieve the effects of improved quietness, prevention of external leakage, and high rotation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

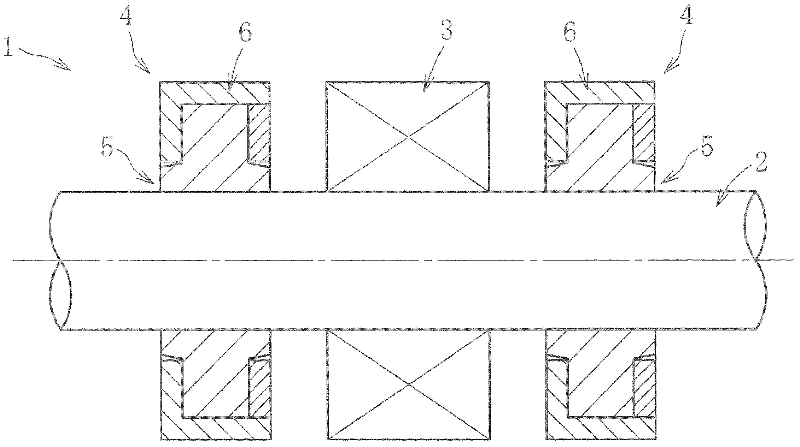

[0049] figure 1 It is an axial sectional view of the sliding bearing unit 1 incorporating the sliding bearing according to the present invention. The sliding bearing unit 1 shown in this figure includes a rotating shaft 2 as a rotating side member, a pair of sliding bearings 4, 4 arranged separately in two places in the axial direction, arranged between the sliding bearings 4, 4 and fixed to the rotating shaft. The motor rotor 3 on the outer peripheral surface of the motor 2 is used as a constituent member. This sliding bearing unit 1 is used by being incorporated into, for example, a ventilating fan motor (more strictly speaking, an inner rotor type motor for a ventilating fan) installed in a living room of a house. Fans (blades) not shown in the figure are installed accordingly.

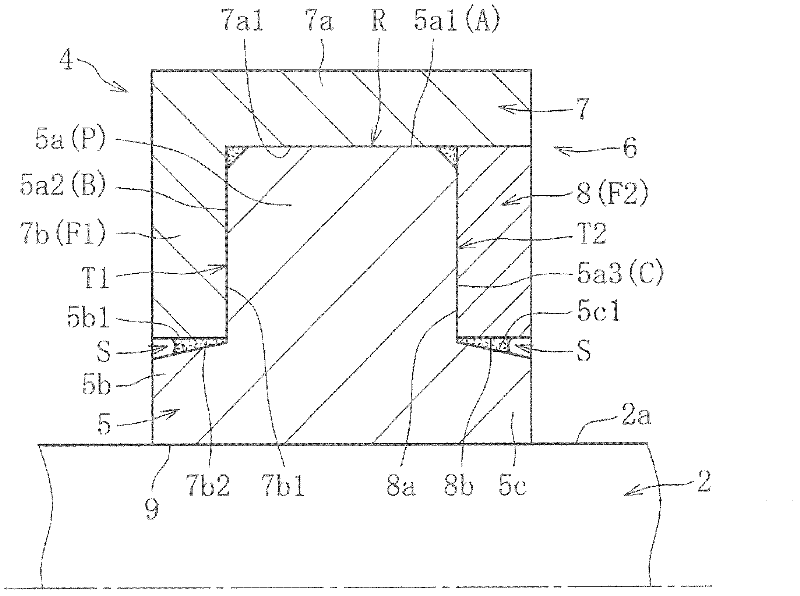

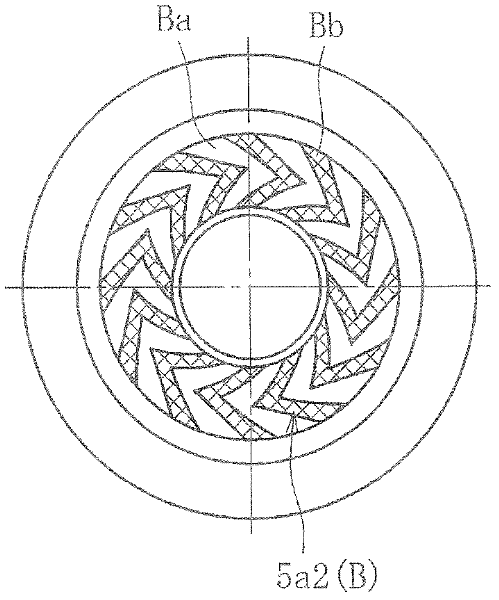

[0050] figure 2 It is a sectional view showing the sliding bearing 4 according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com