Device and method for processing coking wastewater by adopting suspended filler-anaerobic membrane bioreactor

A technology of membrane bioreactor and coking wastewater, which is applied in the field of coking wastewater treatment, can solve the problems of high operating cost and serious membrane pollution, and achieve the effect of reducing operating cost, low operating cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

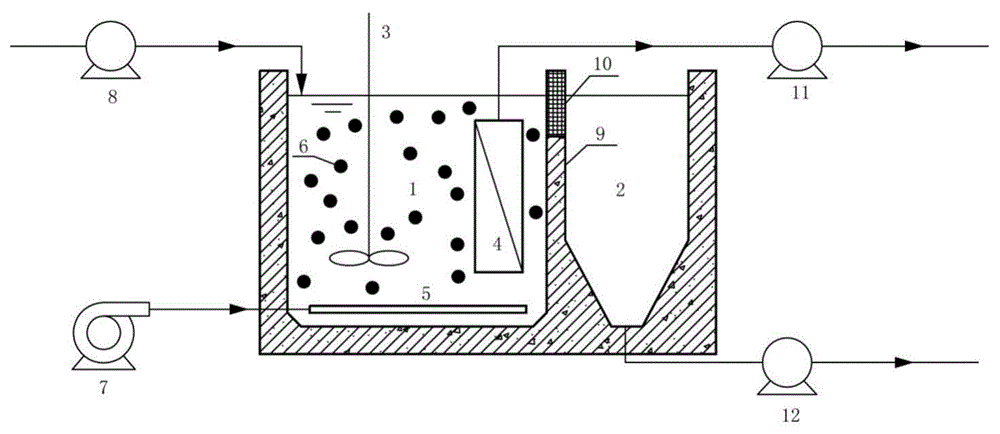

[0020] Such as figure 1 Shown is a schematic diagram of the device structure of the suspension filler-micro-oxygen membrane bioreactor of the present invention for coking wastewater treatment. The device includes a micro-oxygen reaction tank 1 and a sludge settling tank 2. In the micro-oxygen reaction tank 1, a stirring system 3, Membrane module 4, microporous aerator 5, suspension filler 6, pump aerator 7, water inlet pump 8 and suction pump 11; built-in baffle 9 separates micro-oxygen reaction tank 1 and sludge settling tank 2 Open, the upper part of the built-in baffle 9 is equipped with an anti-loss net 10; the influent water is sent to the micro-oxygen reaction tank 1 by the influent pump 8; the membrane module 4 is connected to the suction pump 11, and under the action of the suction pump 11, the effluent is filtered through the membrane module 4 Discharging: A sludge discharge pipe is laid at the bottom of the sludge settling tank 2 and connected to the sludge pump 12 f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com