Pipe electrode with flexible supporting function and function of promoting discharge of machined products and small deep hole electrical machining method thereof

A technology for flexible support and processing products, applied in the direction of processing electrodes, electrode manufacturing, electric processing equipment, etc., can solve the problems of easy deflection of the center line of the tube electrode, limited application, difficult discharge of processed products, etc., to eliminate eddy currents, improve Processing stability and the effect of facilitating timely discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described below:

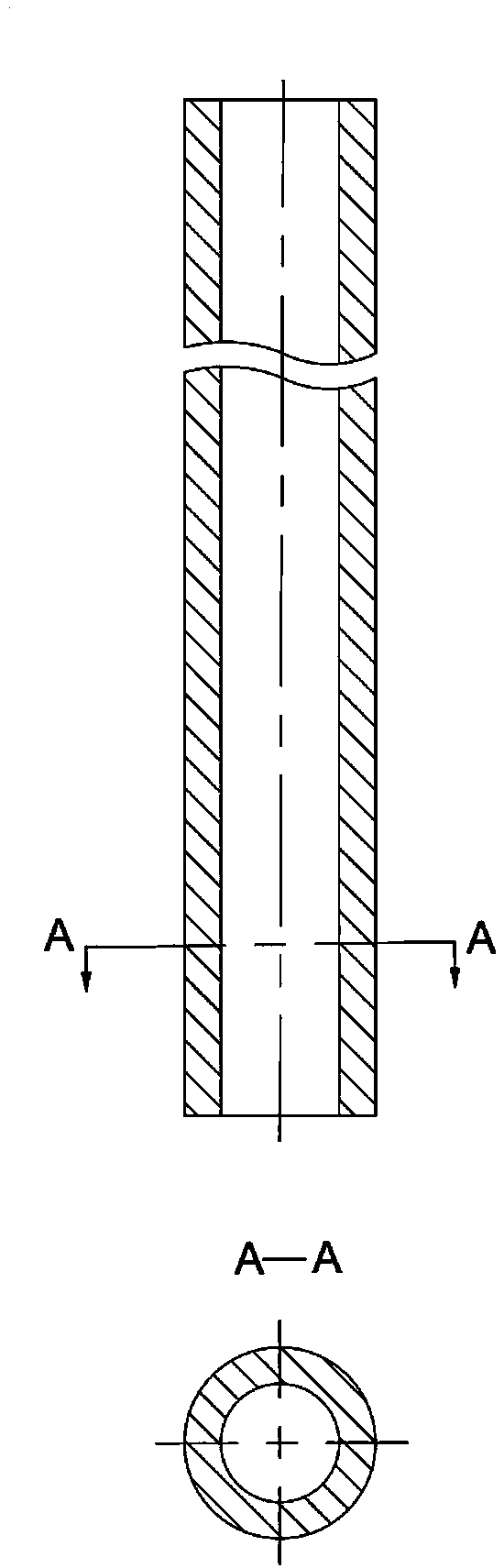

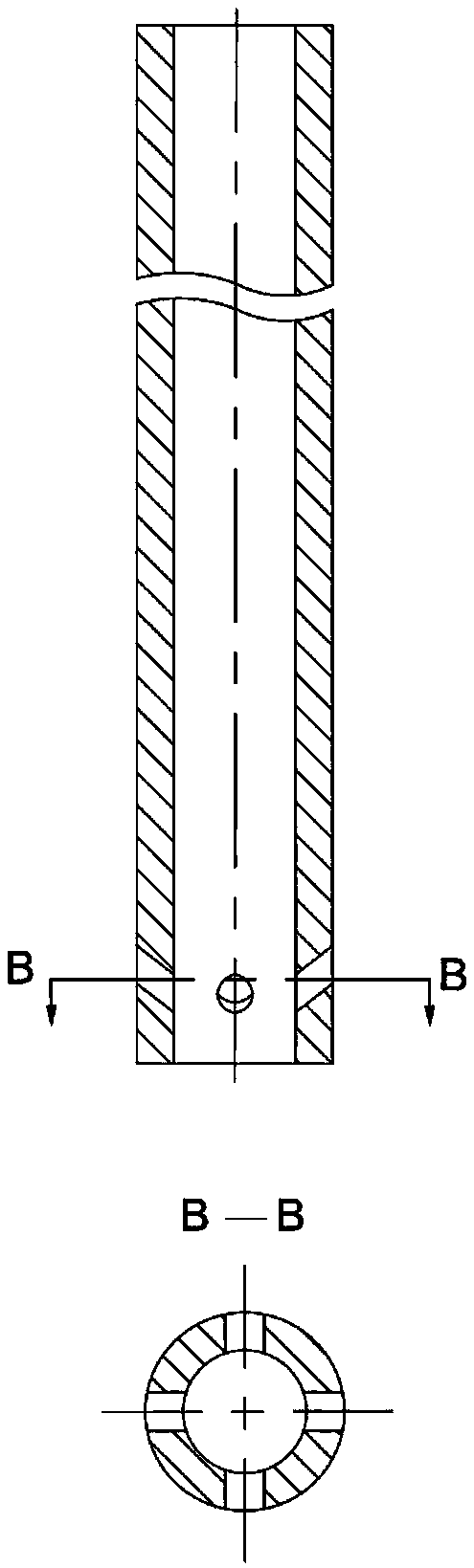

[0024] A through hole is drilled near the discharge end of the tube electrode for EDM, electrolytic machining and combined EDM and electrolytic machining of tiny holes.

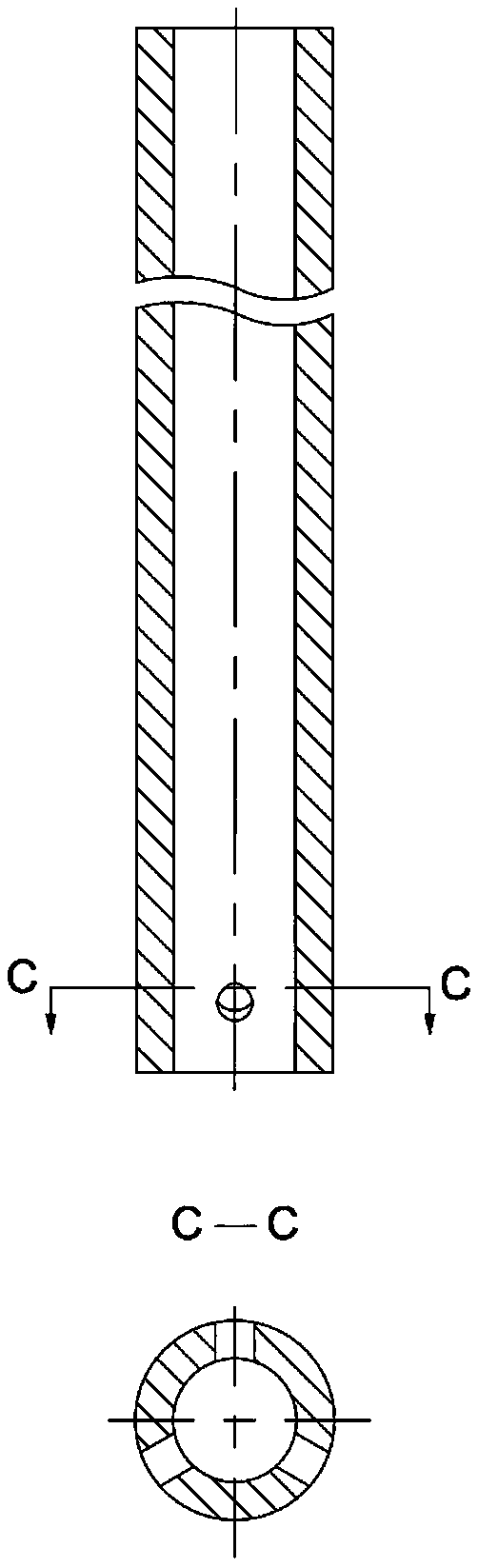

[0025] In order to facilitate the description of the details of the present invention, a specific structure is now selected as an example, that is, four oblique upward symmetrical through holes are processed along a certain cross section at a suitable position at the processing end of the tube electrode, and its processing state is as follows: Figure 8 (a) shown.

[0026] Such as Figure 8 As shown in (b), after the hole processing is completed, part of the working fluid flows out from the processing end of the tube electrode, impacts the bottom of the deep hole, and then flows out from the processing side gap. The other part of the working fluid flows out from the through hole, joins with the working fluid flowing out from the bottom, and flows ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com