Inorganic potassium lithium silicate solution composite organic fluorosilicone coating and preparation method thereof

A technology of potassium silicate solution and lithium silicate, which is applied in the direction of antifouling/underwater coatings, coatings, paints containing biocide, etc., which can solve the problems of insufficient washing resistance and weather resistance, insufficient penetration of primers, and film formation To solve problems such as poor performance, to achieve the effect of wide application range, excellent weather resistance and stain resistance, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

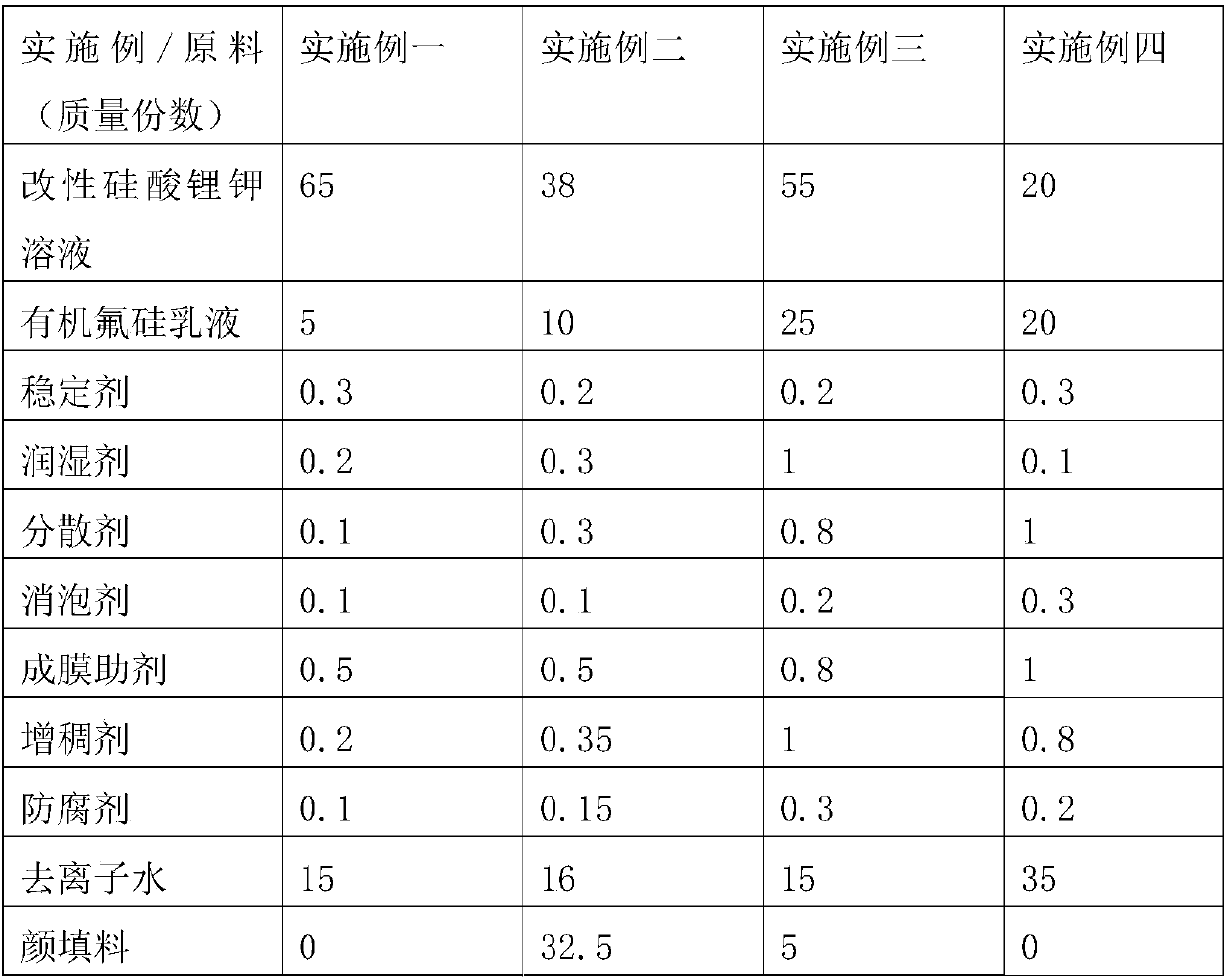

Examples

Embodiment 1

[0034] The raw material composition of embodiment 1 is carried out proportioning modulation, is used for the coating of floor hardener.

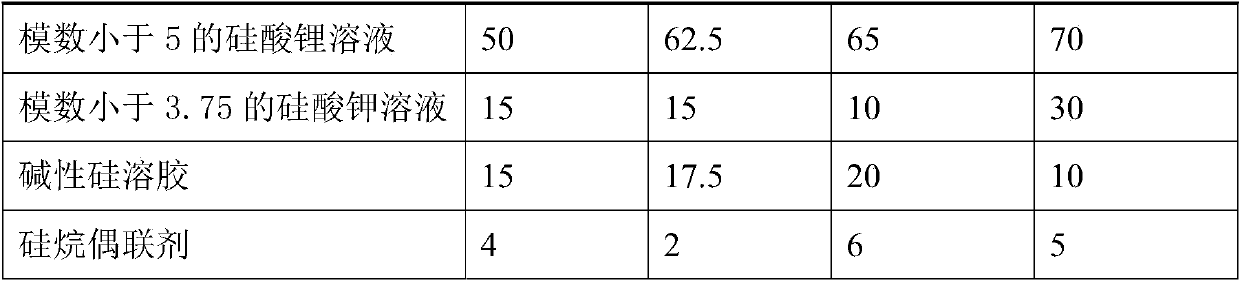

[0035] 1. Preparation of modified lithium potassium silicate solution:

[0036] A. Add 500g of lithium silicate solution (modulus 4.8, mass content 23%) and 150g potassium silicate solution (modulus 3.5, mass content 35%) into the reactor, start stirring and keep the speed at 500-1500 rpm / min Stir well to mix evenly, and slowly heat to 60-65°C.

[0037] B. Increase the stirring speed at 3000-4500 rpm, slowly add 150g of silica sol (silicon dioxide solid content 30%, average particle size 8-20nm) into the reactor dropwise, and complete the dropwise addition within 0.5h-1.0h .

[0038] (3) Slowly add 40g of methyltrimethoxysilane dropwise within 0.5h. After the dropwise addition is completed, under high-speed stirring, keep the temperature at 60-65°C for 1.5-2 hours to prepare about 840g of translucent Modified lithium potassium silicate ...

Embodiment 2

[0047] The raw material components of Example 2 are prepared in a proportioning manner, and are used for the high-grade exterior wall paint with the bottom surface integrated. Its preparation process is detailed below.

[0048] 1. Preparation of modified lithium potassium silicate solution:

[0049] A. Add 250g of lithium silicate solution (modulus 4.8, mass content 23%) and 60g potassium silicate solution (modulus 3.5, mass content 35%) into the reactor, start stirring and keep the speed at 500-1500 rpm / min Stir well to mix evenly, and slowly heat to 60-65°C.

[0050] B. Increase the stirring speed at 3000-4500 rpm, slowly add 70g of silica sol (30% silica solid content, 8-20nm average particle size) dropwise into the reactor, and complete the dropwise addition within 40 minutes.

[0051] (3) Slowly add 8g of γ-aminopropylmethyltrimethoxysilane dropwise within 0.5h. After the dropwise addition is completed, under high-speed stirring, keep warm at 60-65°C for 1.5-2 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com