Preparation method for rare earth oxide doped tungsten powder

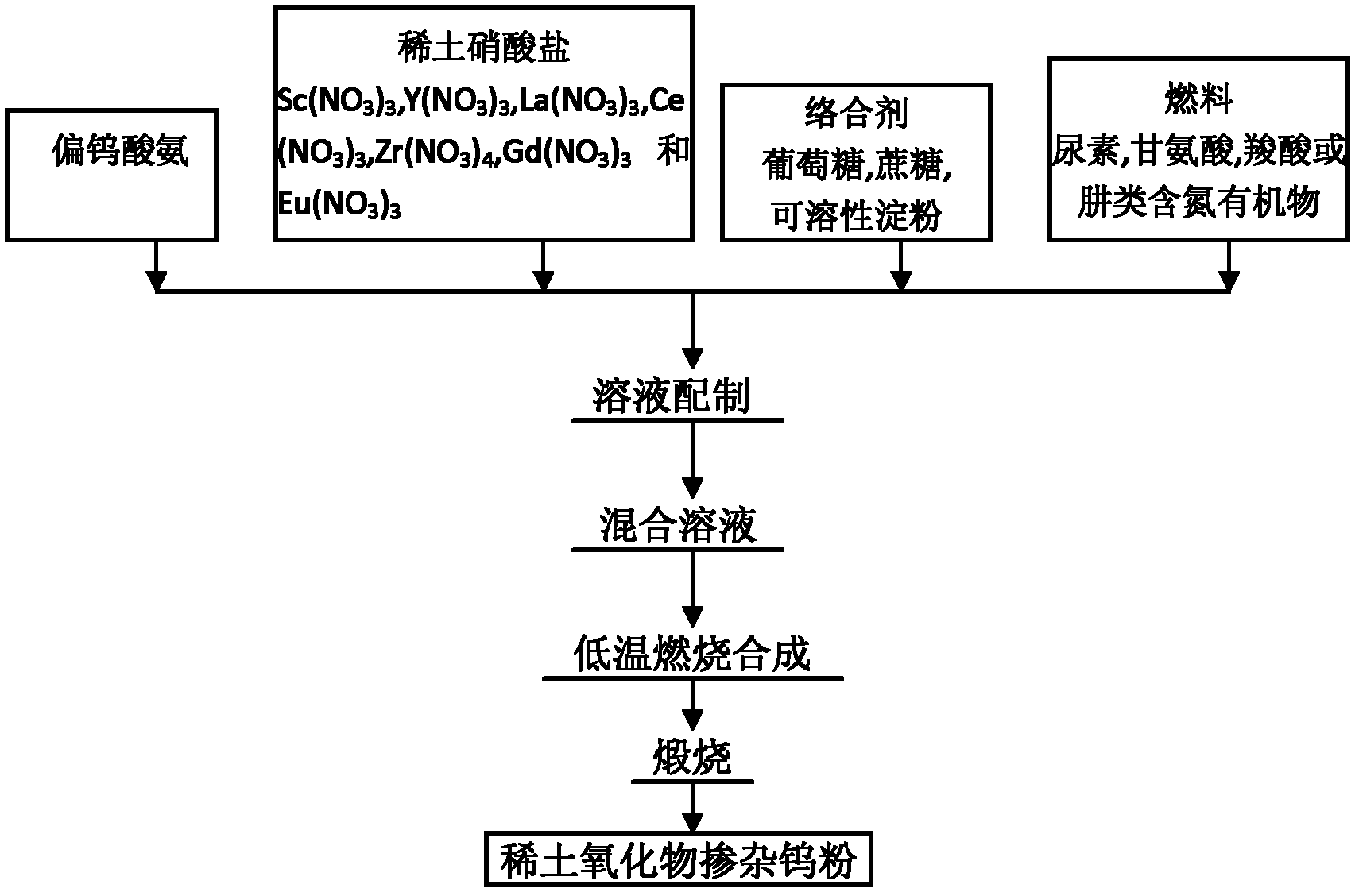

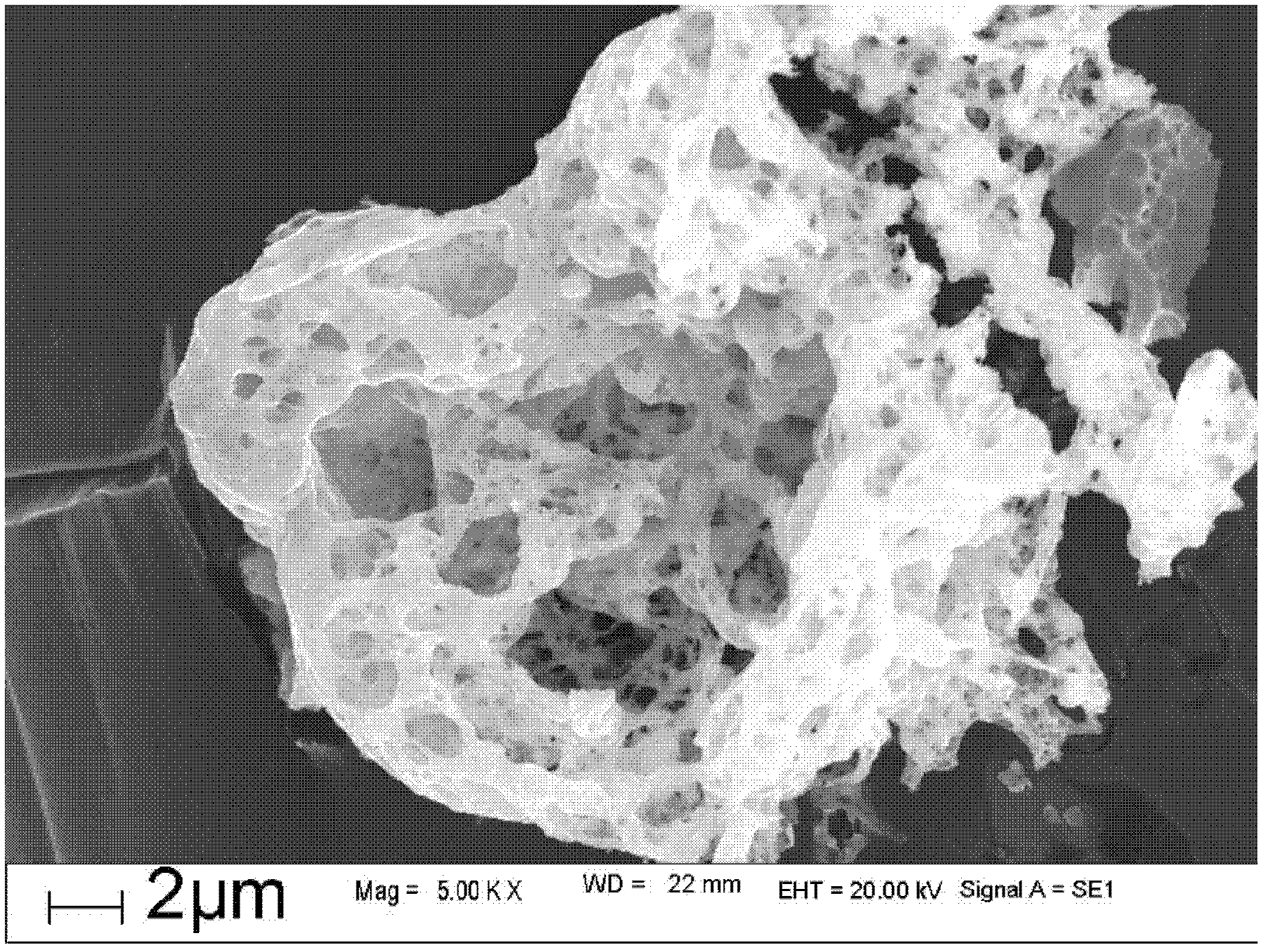

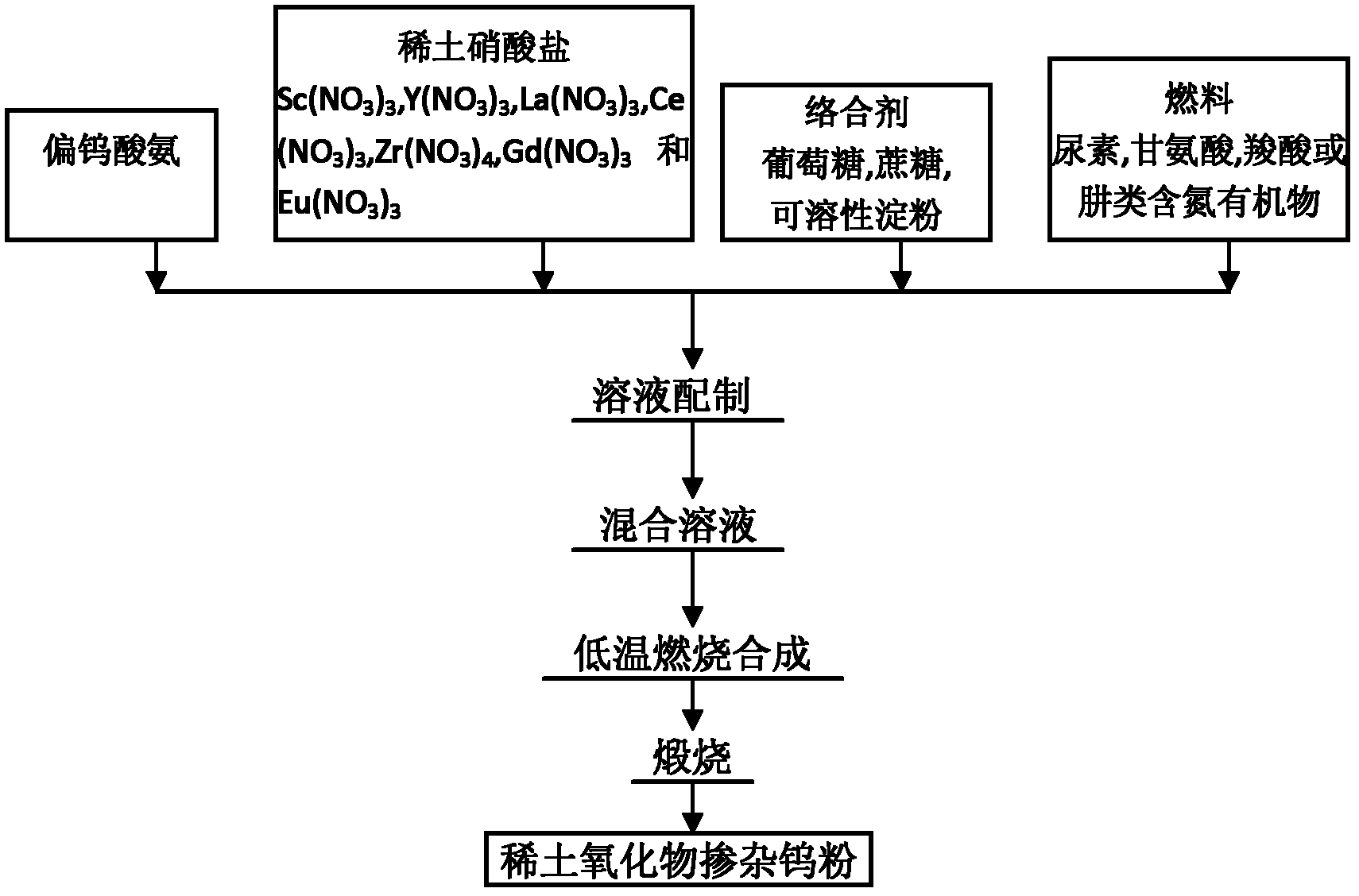

A rare earth oxide and tungsten oxide technology, which is applied in the field of preparation of rare earth oxide doped tungsten powder by low-temperature combustion synthesis method, can solve the problems of rare earth oxide uniformity limitation, oxide segregation, and easy particle growth, and achieve particle size Fine, prevent agglomeration, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: One yuan rare earth oxide doped tungsten powder (W-0.05wt.%La 2 o 3 ) preparation

[0017] To analyze pure ammonium metatungstate, La(NO 3 ) 3 , urea and glucose as raw materials, (NH 4 ) 2 WO 4 and La(NO 3 ) 3 The molar ratio of the sum of the moles of the urea to the urea is 1:0.8, (NH 4 ) 2 WO 4 and La(NO 3 ) 3 The molar ratio of the sum of the molar amounts of the glucose to the glucose is 1: (0.5~2). Weigh according to the composition ratio, dissolve in a small amount of deionized water, and stir evenly to obtain a mixed solution; the mixed solution is heated in a temperature-controllable furnace to volatilize the aqueous solution. As the reaction proceeds, the heat released will cause pyrolysis and carbonization of the complexing agent, and the target element will be converted into extremely fine nano-sized oxide particles and tungsten oxide particles, thereby obtaining mono- or multi-element rare earth oxide particles, tungsten oxide an...

Embodiment 2

[0018] Embodiment 2: Unary rare earth oxide doped tungsten powder (W-1.5wt.%ZrO 2 ) preparation

[0019] To analyze pure ammonium metatungstate, Zr(NO 3 ) 4 , urea and glucose as raw materials, (NH 4 ) 2 WO 4 and Zr(NO 3 ) 4 The molar ratio of the sum of the moles of the urea to the urea is 1:0.8, (NH 4 ) 2 WO 4 and Zr(NO 3 ) 4 The molar ratio of the sum of the molar amounts of the glucose to the glucose is 1: (0.5~2). Weigh according to the composition ratio, dissolve in a small amount of deionized water, and stir evenly to obtain a mixed solution; the mixed solution is heated in a temperature-controllable furnace to volatilize the aqueous solution. As the reaction proceeds, the heat released will cause pyrolysis and carbonization of the complexing agent, and the target element will be converted into extremely fine nano-sized oxide particles and tungsten oxide particles, thereby obtaining mono- or multi-element rare earth oxide particles, tungsten oxide and Precu...

Embodiment 3

[0020] Embodiment 3: One elemental rare earth oxide doped tungsten powder (W-5wt.%Sc 2 o 3 ) preparation

[0021] To analyze pure ammonium metatungstate, Sc(NO 3 ) 3 , citric acid and glucose as raw materials, (NH 4 ) 2 WO 4 and Sc(NO 3 ) 3 The molar ratio of the sum of the moles of the citric acid to citric acid is 1:0.8, (NH 4 ) 2 WO 4 and Sc(NO 3 ) 3The molar ratio of the sum of the molar amounts of the sucrose to the sucrose is 1: (0.5~2). Weigh according to the composition ratio, dissolve in a small amount of deionized water, and stir evenly to obtain a mixed solution; the mixed solution is heated in a temperature-controllable furnace to volatilize the aqueous solution. As the reaction proceeds, the heat released will cause pyrolysis and carbonization of the complexing agent, and the target element will be converted into extremely fine nano-sized oxide particles and tungsten oxide particles, thereby obtaining mono- or multi-element rare earth oxide particles,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com