Low-dielectric constant microwave ceramic dielectric material and preparation method thereof

A technology of microwave ceramics and dielectric materials, applied in ceramics, inorganic insulators, etc., can solve the problems of low dielectric constant, inability to manufacture microwave dielectric devices, small Q f value, etc., and achieve the effect of excellent dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

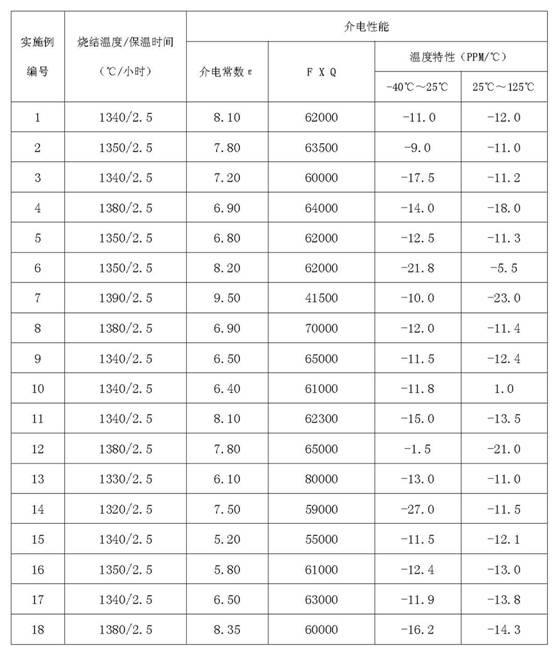

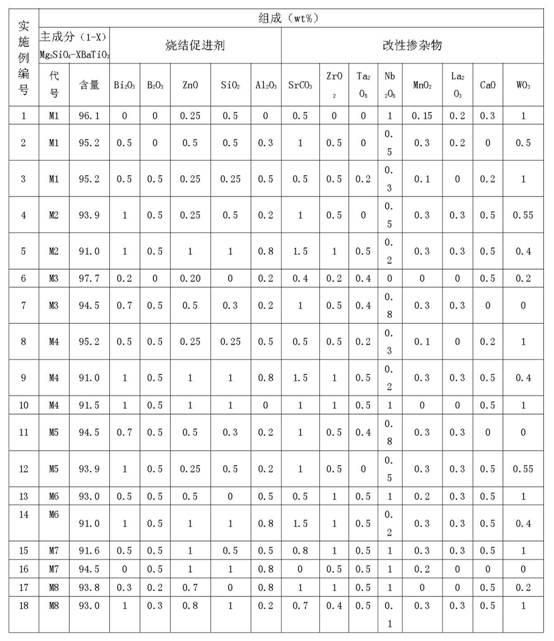

[0014] A microwave ceramic dielectric material with a low dielectric constant εr=3~8 and its preparation method described in the present invention will be further described below in combination with examples according to the above-mentioned content of the invention.

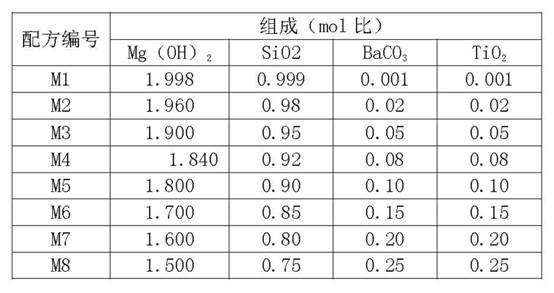

[0015] (1) To analyze the pure raw material BaCO 3 、TiO 2 , Mg(OH) 2 , SiO 2 According to the composition ratio in Table 1, according to the preparation process of the main material described in 1 of the Summary of the Invention, (1-X)Mg was prepared after ball milling, drying, pre-calcination, crushing, filtration, etc. 2 SiO 4 -XBaTiO 3 .

[0016] Table 1 Main material (1-X) Mg 2 SiO 4 -XBaTiO 3 Example recipe of

[0017]

[0018] (2) According to the composition of Table 2, the main material is (1-X) Mg 2 SiO 4 -XBaTiO 3 , where X=0.001~0.25 add analytically pure SrCO 3 , ZrO 2 、 Ta 2 o 5 , Nb 2 0 5 , MnO 2 , CaO, La 2 o 3 、WO 3 、 Bi 2 o 3 , B 2 o 3 、Al 2 o 3 , ZnO, SiO 2 , addi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Τf | aaaaa | aaaaa |

| Dielectric properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com