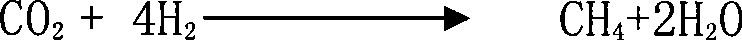

Novel methanation catalyst and preparation method thereof

A methanation catalyst, catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high cost and achieve good conversion rate and selectivity , the effect of simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 500g of pseudo-boehmite, add 350ml of nitric acid solution with a mass percentage content of 2%, knead for 30 minutes, extrude into φ3 strips, dry at 120 ° C for 12 hours, and then calcine in a muffle furnace for 5 hours to obtain Catalyst carrier JWZ-1, carrier specific surface 194m 2 / g, pore volume 1.2ml / g, take 900g of nickel nitrate hexahydrate, 55g of lanthanum nitrate, 52g of magnesium nitrate, dissolve in 100ml of deionized water, put the carrier JWZ-1 into the dipping solution, keep the dipping temperature at 80 ℃, dipping After 6 hours, the remaining impregnating liquid was filtered off, put into an oven for 18 hours at 120 °C, and then placed in a muffle furnace for calcination. The heating rate was 4 °C / min, the temperature was 500 °C, and the constant calcination time was 4 hours. The methanation catalyst JW-1 was obtained. The specific surface is 146m2 / g, pore volume 0.44ml / g.

[0036] The reaction temperature is 300℃, the reaction pressure is 1MP...

Embodiment 2

[0038] Weigh 500g of pseudo-boehmite, add 150ml of acid nitrate solution with a mass percentage of 2%, weigh 55g of lanthanum nitrate, 45g of cerium nitrate, and 52g of magnesium nitrate, dissolve in 220ml of deionized water, and add to the pseudo-boehmite. The kneading time was 30min, extruded into φ3 strips, and then dried and calcined. The conditions were the same as in Example 1, and the carrier JWZ-2 was obtained with a specific surface area of 186m. 2 / g, pore volume 0.9ml / g. Dissolve 900 g of nickel nitrate in 110 ml of water, put the carrier JWZ-2 into the impregnation solution, keep the impregnation temperature at 50°C, and the impregnation time for 6 hours, then dry and calcine to obtain the catalyst JW-2 with the same conditions as Example 1. The specific surface area measured by BET is 167m 2 / g, pore volume 0.53ml / g.

[0039] The reaction conditions are the same as in Example 1, and the conversion rate of carbon monoxide is 100%, and the selectivity is 100%. ...

Embodiment 3

[0041] In the process of making the carrier in this example, 0.9g of calcium nitrate was added, and the preparation method was the same as that of Example 2, to obtain the carrier JWZ-3 with a specific surface of 193m. 2 / g, pore volume 0.87ml / g. The catalyst preparation method is the same as Example 2. Get catalyst JW-3

[0042] The catalyst specific surface is 166m 2 / g, pore volume 0.49ml / g.

[0043] The reaction conditions are the same as in Example 1, and it is determined that the conversion rate of carbon monoxide is 100%, the selectivity is 99.91%, the conversion rate of carbon dioxide is 99.90%, and the selectivity is 100%. The catalyst is subjected to a heat resistance test. After the test is run at 700° C. for 2 hours, the conversion rate of carbon monoxide is 100%, the selectivity is 100%, the conversion rate of carbon dioxide is 99.30%, and the selectivity is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com