Desulphurization method for sintering flue gas by using pyrolusite and rhodochrosite

A technology of sintering flue gas and rhodochrosite, which is applied in the field of flue gas desulfurization, can solve the problems of difficult desulfurization by-products, lack of flue gas desulfurization technology, high construction and operation costs of flue gas desulfurization equipment, and achieve increased equipment investment and stable desulfurization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

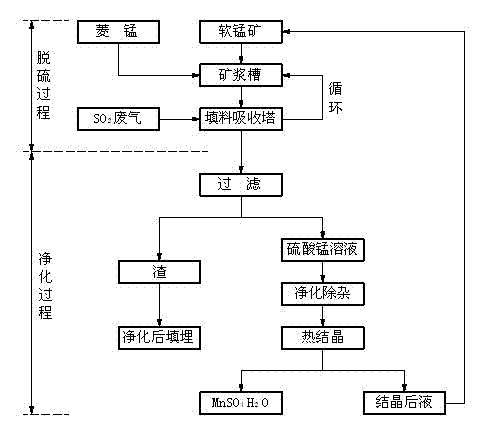

[0015] A method of desulfurizing sintering flue gas by using pyrolusite and rhodochrosite, utilizing the reducing SO in sintering flue gas 2 and oxidizing MnO in poor pyrolusite 2 Oxidation-reduction reaction occurs in the manganese ore slurry, and the reduction reaction temperature is 80-120°C, and the SO in the sintering flue gas 2 Removal; crush pyrolusite and rhodochrosite into particles with a particle size of 0.075mm, add 5 times of clear water to the rhodochrosite and mix to make a manganese slurry with a pH value of 2.5 to 3.5, and the flue gas enters the absorption after dust removal The desulfurization and manganese leaching process is completed in the absorption tower; the desulfurization rate is greater than 92%, and the manganese leaching rate is more than 80%. The mother liquor is filtered, pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com